Community Tip - You can Bookmark boards, posts or articles that you'd like to access again easily! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Profile with ramp

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Profile with ramp

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Profile with ramp

Did anyone achieve a profile sequence where the tool follows a ramp trajectory? I tried differrent ways but it always keeps a 90 degree step down.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

Data Exchange

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

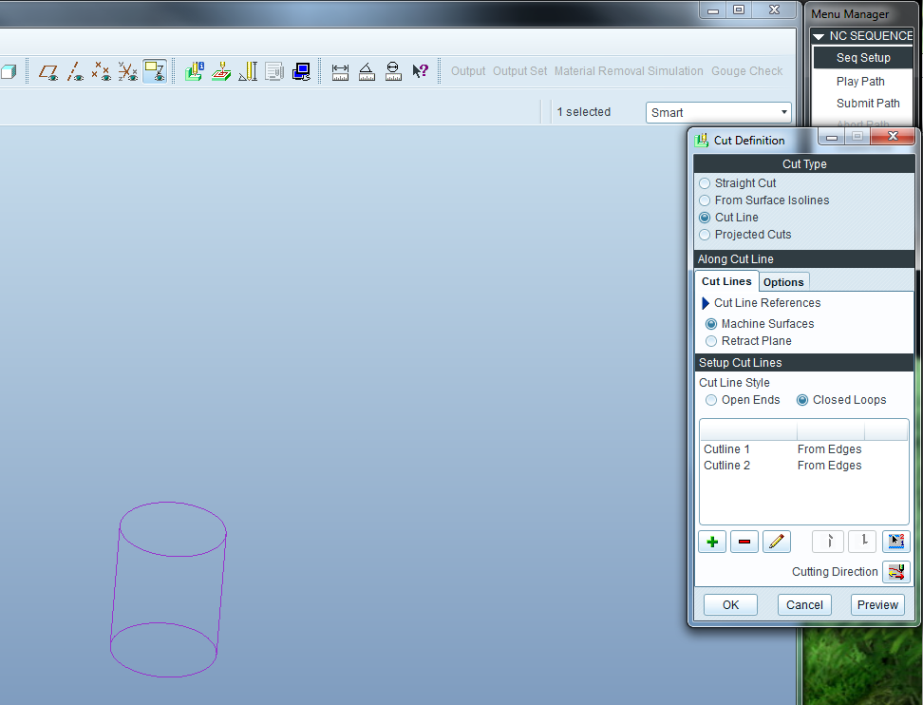

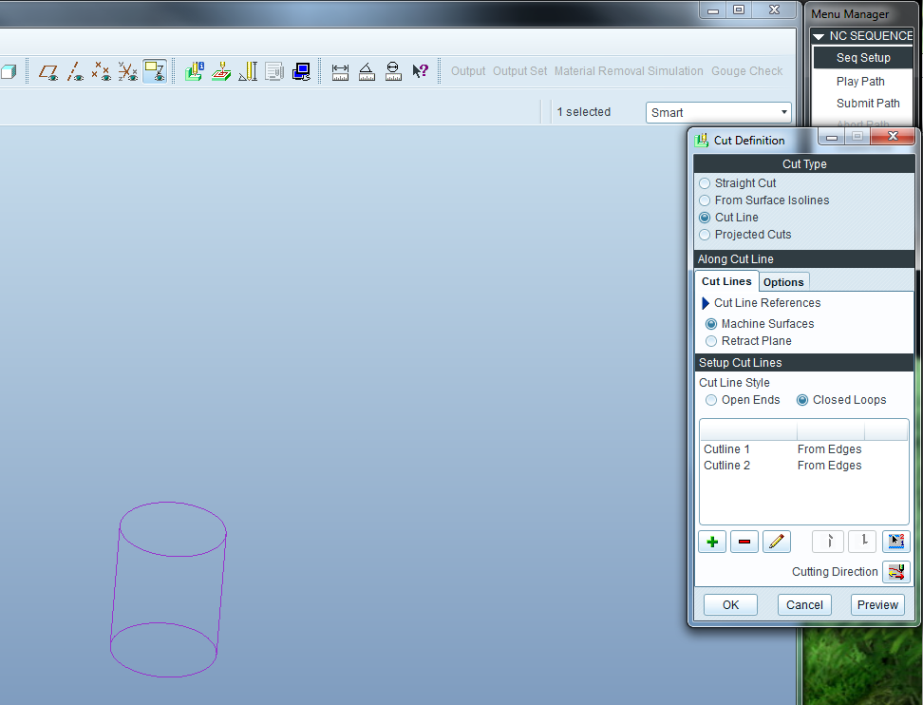

If you are milling holes I can help. create a surface mill sequence choose the surfaces of the hole or define your mill surface. Use cutline closed loops

after that is setup, go back into the parameters and choose scan type TYPE_HELICAL. Your step over will control the angle of the helix. Be aware that this will generate all point to point CL data. (no circle statments will be created)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I belive that functionality is under development.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That's rich. Why would they sell the software then?I' m starting to loose my patience with PTC.If it would really work, I could use a spiral trajectory when machining holes. Instead of Volume Rough I could use Profile, if only the ramp option would work.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you are milling holes I can help. create a surface mill sequence choose the surfaces of the hole or define your mill surface. Use cutline closed loops

after that is setup, go back into the parameters and choose scan type TYPE_HELICAL. Your step over will control the angle of the helix. Be aware that this will generate all point to point CL data. (no circle statments will be created)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I usually use volume rough with profile and ramp. Step depth bigger than the depth of the hole and upcut instead of climb. Sometimes it works , sometimes it doesn't , even on the same type of holes. The idea is to get the fastest method to do the sequence. The more design tools needed, the more time spent unnecessary. I'll try your method also. Thanks.

Have you read what I wrote about the re-roughing? What do you think?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I also suggest trying a Finishing sequence and exlude the surfaces you do not want to finish or use the slope angle to control what to finish. I am using Finishing more and more with excluded surfaces. you can create a auto window in a few clicks then depending on your geometry use exclude surfaces or parameter settings to control where to cut.