Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Screw Connection Cast Iron/Cast Iron

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Screw Connection Cast Iron/Cast Iron

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Screw Connection Cast Iron/Cast Iron

Hi everyone,

Here David, new user of PTC Creo Simulate.

Hope you can help me with this question.

As far as I´ve read about screw connection, there are different possibilities to simulate a screw connection.

As you can see in the file Pic.jpg, my assembly is a round plate, supported in the inner face of a round structure. There is a screw connection along the contact surface between plate and structure.

At the begginig I wanted to be the most accurate possible. So I created with the Intelligent Fastener Tool all the screws (10.9. M24x100). Once I had them. What should I do? I started to create "interfaces" (Simulate>Refine Model>Connections) between each screw and plate, and also each screw and structure. Also structure and plate interface. I wasn´t sure about it, there were a lot of connections. In my experience with Marc Mentat in University, you can select easily all the contacts with a contact table.

Anyway I did that. I wasn´t sure so I choose other option: create fastener in Simulate>Refine model>Connections>Fastener

Once I've done it, what should I do? Create also interfaces between each screw with structure and plate?

Also, Interface between plate and structure should be created??

Thanks a lot in advanced, as you can see, I have a "interface" doubt, don´t know

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Can't help with the details of how to approach the fasteners; but your part appears from the sketch to have cyclic symmetry. If your load also has cyclic symmetry, then for analysis purposes I would cut away all but a single 'pie slice' of the model, and just analyse one sector with one fastener. This will slash your run times and/or allow you to use a much better mesh / more detailed model. It will also mean you only have to create interfaces and other features for one fastener instead of all of them!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for the answer.

My draw was without details, but not, it´s not symetrical, it has kind of windows, and a hole where an input shaft comes in.

My question anyway:

Should I create always Interfaces?

Because If I don't, the simulation would think that both parts are one (like one piece),

am I right?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can simulate all sorts of things, but the first question is: what are you trying to accomplish? Without going into FEA terms that is. For example: "I want to check if the pretension in the bolt is sufficient for this application", or "I want to check if the bolt does not strip the threads from the cast iron part".

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I want to see If how much is the allowable stress, to calculate with that my safety factor.

Should I always create interface between two parts in Simulate (because they are different .prt in the same assembly)?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Paul,

Thanks for this nice example.

For those that might be interested, I found a document a little

similar to the WF 4.0 but in German.

Kind regards.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Paul,

Bravo it is beautiful.

I had not made the rapprochement between the names. Sorry.

I have the first version 2009 WF4.

Well, it seemed to me that the model was similar to the book.

I have other books of SDC Publications on the subject.

You edit a Creo 3.0 Simulate version?

If this is the case, from what seems to be I the command.

Since the inception of RASNA, it is difficult to find books

Advanced ProMechanica simulation.

Kind regards.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Denis,

my (last) "Pro/MECHANICA" is Creo Simulate 2.0 M080.

I will write no more book of Pro/MECHANICA.

Regards

Paul

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Paul,

You say that your latest work extends to Creo Simulate 2.0 M080.

but the indication on the book is:

Pro/ENGINEER Wildfire® 4.0 für und Creo Elements/Pro 5.0 (Wildfire® 5.0).

It is the latest version of 2012.

Kind regards.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sorry,

not my book, I use Creo Simulate 2.0 M080.

Regards

Paul

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

No worry.

Thanks for the information

Kind regards.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks!

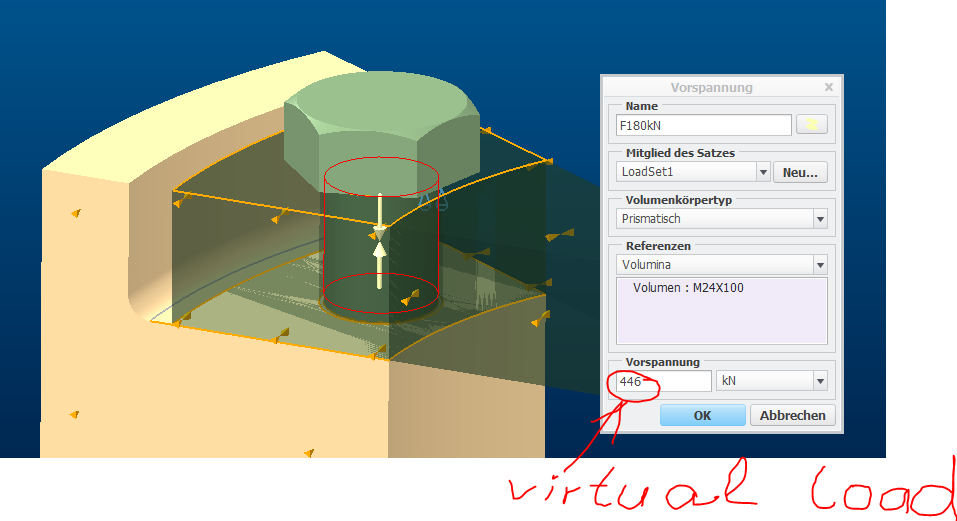

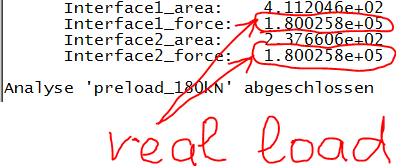

How you made to apply the preload in that part of the screw?

I mean, I see with a volume region, but why those measures?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

bolt preload:

Regards

Paul

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

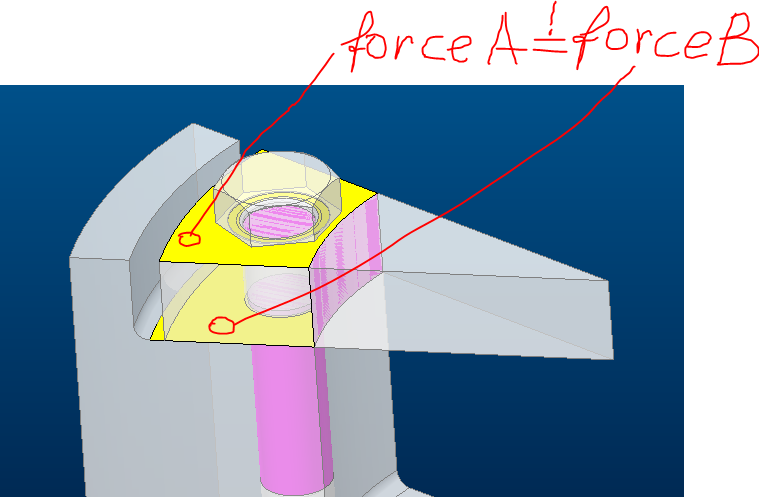

Hello Paul,

I would like to take to ask some information.

It is interesting to see how you did.

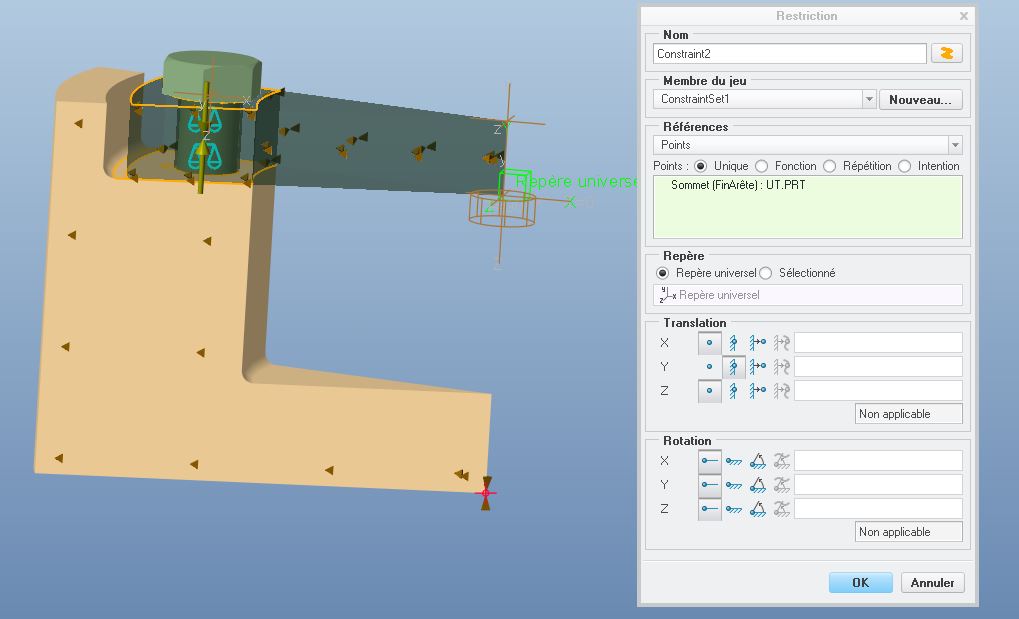

For the restriction you could use:

define a cyclic symmetry restriction?

Is there a downside to using it?

The point that you have forced to the center of the tank, see the attached image, is to stress the whole?

Otherwise would it have been possible to use the inertial balance loading, which removes the possibility of Non-linear.?

Kind regards.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Denis,

cyclic symmetrie ist for rotation, simulate help:

Y-fixed point is for static analysis significant.

contact is non-linear, always

Regards

Paul

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Paul,

Thank you for these valuable explanations and demonstrations.

Kind regards.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Good day David - welcome to PTC Community and I am glad to see you were able to find an answer to your question.

Best,

Toby