Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Sheet Metal unbend (eccentric) cone with marku...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Sheet Metal unbend (eccentric) cone with markups

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sheet Metal unbend (eccentric) cone with markups

Hi,

I have drawn an eccentric cone part, that I can unbend without any problems.

But, if we would like to make this part ourself, we need some markups on the flat pattern. (bend lines that show where to place our press to bend the part)

I need to define the lines/markups/... in the bended situation. They need to be transferred to the flat pattern correctly.

We need these markups for almost every sheetmetal part we want to make.

Does anyone know how to do this?

We are switching to Creo (version 2.0 M030) at this moment, we used autocad until now.

thanks a lot,

Jeroen.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As long as I aligned the default datums between the two part, it all lined up perfectly. If I aligned the datums created in the flat state, things shifted. Funny how that happens! Anyway, see attached Creo 2.0 files to see how this was accomplished:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You will have to create the bends individually in the part arranged as you envision them being formed by the tools. Doing this will provide the flat pattern with the bend information for the shop.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creating the bends individually isn't an option for us...

In this particular case, where we try to approach a perfect cone by bending the plate in X steps (for example every 5°), you are correct in theory. But I think it is not usefull to draw this eccentric cone in many individual bends because our bending will result in a nice eccentric cone, not a plate with 20 bends.

Another thing we really need, and this is pretty much the same issue:

We produce large vessels. The cylindrical parts have cut outs for nozzles. These openings are nicely unfolded and positionned on the flat state. But we also make markings on the plate. These markings are defined in the folded state, in the 3D model. These markings are needed to position internals, externals, references, ...

It is ease to place a datum point or a datum CSYS or whatever on the correct place. But these points/CSYS/ ... need to be visible on the flat state on the correct position. While lasercutting these plates, we also create these markings at the same time.

This issue is the same problem as for the eccentric cone: we need to transfer some 3D-information/positions to the 2D flat state (points, lines, CSYS, ...).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Now I understand better. You should be able to make the part by forming it in the shape you want. You can unbent it and add the features you want to laser onto the faces. And then you can bend back the form to get the end result. For the drawing you can use the unbent state. In most cases, you can use relations to control exact positioning on the flat form. It is your choice as to what types of features you want to use for the laser etching, but my recommendations might be to make them shallow extrudes.

Alternatively, the markings could be done with a decal. You can apply the decal parametrically and you can use it in the drawing, but you will still need features to dimension to.

You really can make those 5 degree bends fairly smooth in Creo. Is the fabricator using dies with varying bend radii (conical) along the length? I don't know that Creo will do this with sheetmetal. For something like that I would go back to core modeling. It wouldn't be the 1st time I've had to use two models to define a product; one in the flat and on "rolled out" (rather than unfolded) when it comes to intricate cylindrical machining requirements.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for your answer.

But I my request is slightly different.

We would like to mark the correct position on the 3D model (bent state) . In the flat state, we can then add features or shallow extrudes to show the laser markings. But we need the correct position in the first place.

But I have tried many things to do so. Sketches, datum objects, ... all of them stay floating in thin air when unbending.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I was suggesting using circumference relations at specific locations on the cone when in the flat state. Cut a section through the cone in two places where you want to put the reference ticks. Measure and capture that diameter with a dimension. In the flat state, lay out an arc on the flat pattern that represents that earlier section. Now use distance along that arc to find your tick marks. Place one low on the cone, and one high on the cone. You can then connect the tick marks.

Of course, you can punch holes in the formed cone and then unbend and fill them in after you use them as references.

I have noticed how awkward many of the non-physical features are with bend and unbend states. Sometimes they move, and other time they don't. We just have to become more clever than the machine.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I was affraid that this would be the correct answer 😉

I was hoping on a setting or method to let CREO project the markings to the flat state. Hopefully something for a next version of Creo?

Nevertheless, thank you very much for your answers!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You got me curious and I learned a few things more about sheetmetal. 1st of all, how to unbend a cone ![]()

But I did get "Project" to work in the cone and retain the definition through to the flat pattern. The idea is that you can project a datum curve onto the face of the cone.

Where things go wrong is when you want to engrave or otherwise change the thickness of the unbent version. You can cut through the material, but you cannot make shallow cuts. I suspect you have to use forms in order to make "impressions" in order to have the bend/unbend/flat pattern features continue to work.

I have included all 3 feature types that are supported in the attached image. This is Creo 2.0... let me know if you would like the model to review.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Edit: Cool tip #1: ...and sort of interesting.

You can revolve/remove along the outside of the cone and as long as you flatten the form feature in flat pattern, it will still function. Therefore, I did finally get a "thinned section" that create the flat pattern as long as the "flatten forms" is selected but you can no longer unbend the affected section. This might be helpful as a last feature in the formed state.

I have attached the 2 files needed to have a look (cone_test.zip). Again, Creo 2.0 full version.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you like to experiment, I'll give you a nice one... 😉

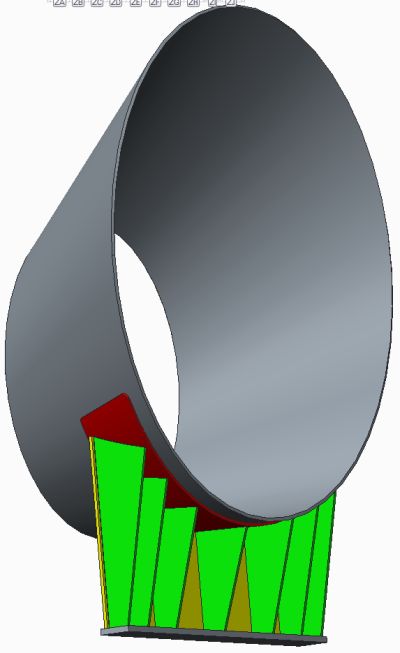

I'm working on a saddle for a pressure vessel. The saddle is on the eccentric cone part, like you can see on the picture below from a previous project. The saddle is made from a base plate that is mounted on the floor, a vertical plate with several ribs to provide rigidity, and a formed plate that connects to the vessel. The formed plate is pretty much an eccentric cone, but not quite.

The internal face of the eccentric cone is a mathematical correct eccentric cone. But, because of the fact that it is a sheetmetal part (both in creo as in reality), the thickness of the cone is (almost) constant NORMAL to the internal surface. The outside of the eccentric cone, will be the inside of our formed plate. This is an eccentric-ish cone, and this is the starting point for our formed plate.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Wow! What a pain for such a simple requirement.

I think I have a robust solution:

- Make the original cone with the controlled surface on the outside (thickness to the inside)

- Make sure it unbends easily perferably with the fixed geometry at the saddle

- Create datum planes as needed to control the saddle shape in the flat state

- Copy the part

- Reverse the material direction (and thickness, if applicable). The "outside" now becomes the "inside"

- Unbend

- Extrude the desired shape (works very well if a rectangular form is desired as a work piece) in reverse (save only the extruded region and remove the rest of the cone)

Now the part Bends Back and Unbends without issue.

Let me know if that makes sense.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As long as I aligned the default datums between the two part, it all lined up perfectly. If I aligned the datums created in the flat state, things shifted. Funny how that happens! Anyway, see attached Creo 2.0 files to see how this was accomplished:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you very much for the information and the effort you put into this.

To situate what we are doing:

2 years ago our company decided to 'evolve' from 2D (autoCAD) to 3D.

There were many requirements from our side, so we made a list of things that we think are very important for us to be able to do in 3D. Afterwards we contacted all large players in 3D CAD design, and they all said very quickly that it wasn't a problem to do so with their program.

Then we asked to prove this with a little proof of concept. All of them failed, except for a company (Savaco) that is specialized in Creo, and they showed us a working proof of concept, built in Creo (Pro/E), with the use of EVX.

And so Creo it is...

1,5 years ago we started an advanced training to master Creo (with 2 persons, the other designers get their training after we built up the vessel designer). We finished the complete training, but then due to some internal issues, the training was put on hold.

Now, 1 year after the original training, we are again working with Creo. To refresh our knowledge we started to go through the tutorials again, and we tried to create some basic models we use. And then we tried these saddles.

Many of our vessels use these saddles, so it is interesting to make them very adaptable with parameters and relations. The idea is to draw this once, and afterwards we only need to regenerate the drawings to build the saddle.

So, to make a long story short: It was difficult to start over again after 1 year of not drawing at all, and we never used Creo or Pro/E before. Thanks to many ideas and hints we gathered on the internet, and with your help of course, we now have a fully working model that van be used for almost all our vessels, just by adjusting a few parameters.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Your company's situation is certainly not unique. The demand on the cad platform is indeed more than one would first glean from what would seem simple. Having gone through the exercise, I certainly understand.

That EVX is an interesting module.

I am glad you are up and running and am happy to be of some help in the process.