Community Tip - You can Bookmark boards, posts or articles that you'd like to access again easily! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Show-Off Your Projects!

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Show-Off Your Projects!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Show-Off Your Projects!

No humble brag here. Show us what you're working on or have done in the past. Impress us!

Who's got the biggest assembly??

Who has the most complex part??

Let's see it...

- Labels:

-

Assembly Design

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here's my large assy! Unfortunately, it's almost completely obscured by rogue datum planes.

800,000 lbs of mostly steel 563" (14315mm) tall

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is what it looks like on in storage on a ship.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Looks like a lot of weldments. how many parts?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Part count is a little tricky. I rarely open the entire assy.

The "lower" assembly I have open now has just over 1000 workspace objects. The upper assembly has a larger part count but I don't have it readily available.

A quick look tells me ~3900 parts in the lower assy but i'm not sure if that includes items excluded via simplified rep.

Rough guess 10000 parts in the the whole creo assembly. Would be considerably more but some of the hydraulic controls stuff has to be completely dumbed down so I can show them.There 2 hydraulic pods that probably have ~10000 parts each and 2 that have ~2000 each. I can't handle those assemblies with all the other stuff so I just make envelope parts to show in my models.

My job is the big picture and includes the big weldments. Other groups are responsible for the hydraulics, valves, electrical etc that actually do the work so to speak. It's really passive safety equipment so a normal workday means nothing actually gets used or only gets functioned for testing, in general.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

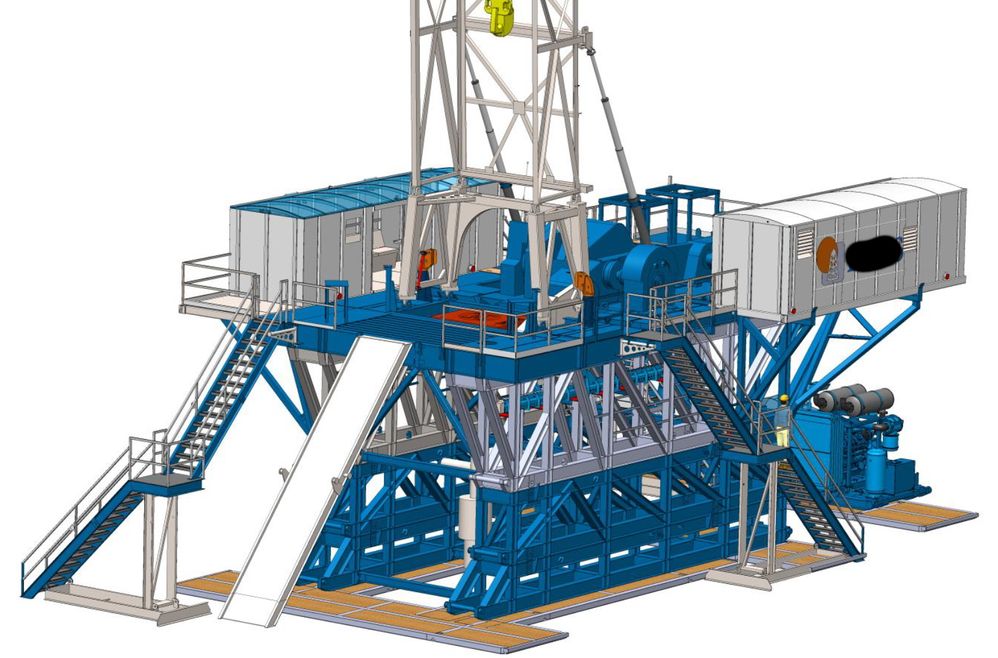

Thanks, I was doing O&G stuff for awhile on SWX. Here's one drilling rig that was over 10k parts and growing.

Here's a pump truck, can't remember how many parts this was:

Can't imagine having to go back to 2D or paper...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Other parts of my company does rigs and trucks and, well, pretty much everything else energy related.

Creo, Solidworks, NX, Inventor, Autocad are all common within different groups.

I worked on trucks/skids at Halliburton. Looks very similar except RED/Gray. Only it's was all 2-1/2D wireframe (CADAM mainframe) so there was no shaded views (1990-ish)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

you must be in Texas?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes sir, Houston. But the Halliburton gig was in Oklahoma.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I worked for a few years for FormaCars, a builder of custom, high end kit cars based on Factory Five kits. Their big differentiator is modern, custom interiors. The blue and white is the custom interior I developed for their Type 65 coupe builds. A couple of CAD screenshots and a picture of the finished product. The red and gray is for the Factory Five Mark IV (Cobra).

The tube chassis is from Factory Five, constructed in Creo based on measurements, so we could make the interiors within it. Parts are largely 3D printed, FDM or the new HP 3D print technology, and upholstered in vinyl.

I did a bunch of other projects, including HVAC systems and more, but the interiors are among the most complex and the fun ones to look at.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

stitched leather? That must have been fun.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

curved "brows" were a bit challenging, but the rest was pretty

straightforward. Well, once we figured out how break up the printed parts

to allow for simple wrapping and to hide the excess vinyl and the seams. I

had to make sure to account for the multiple layers of vinyl in the 3D

printed parts, however.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We use Creo for jumbo structural glass building facade projects and other facade projects. We typically have very simple parts but very large assemblies.

Capture6 below is a photo of the final project. I didn't have time to open the Creo model.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is some cool stuff there. I don't generally expect to see these types of projects in Creo.