- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Sketching multiple options, then passed to a s...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Sketching multiple options, then passed to a single extrude via a family table?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sketching multiple options, then passed to a single extrude via a family table?

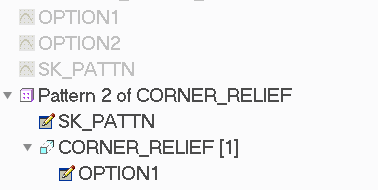

I have a part that is going to have a series of corner relief options as sketches (OPTION1, OPTION2 in image below) to be used in an extrude feature (CORNER_RELIEF) that is patterned. Is there a way to use a Family Table to pass the name of the sketch (OPTION#) to a single extrude feature to create all the part variations? I'm trying to avoid have to create the same extrude pattern in each instance referencing a different sketch.

Solved! Go to Solution.

- Labels:

-

Flexible Modeling

- Tags:

- family table

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Family tables AFAIK are not a conduit to swap out a sketch in a feature(s). The table can include or extrude a feature as you probably already know.

If I understand, you have a part with a patterned cut present. You want to be able to redefine the sketcher geometry reference of the pattern leader in order to switch between two sketched shapes.

Have you considered using a reference pattern scheme that would define the location and orientation of each pattern member and then using that as a reference for different shaped cuts? This way you manage the pattern control in a single pattern and reference that as required for different shapes.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Family tables AFAIK are not a conduit to swap out a sketch in a feature(s). The table can include or extrude a feature as you probably already know.

If I understand, you have a part with a patterned cut present. You want to be able to redefine the sketcher geometry reference of the pattern leader in order to switch between two sketched shapes.

Have you considered using a reference pattern scheme that would define the location and orientation of each pattern member and then using that as a reference for different shaped cuts? This way you manage the pattern control in a single pattern and reference that as required for different shapes.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

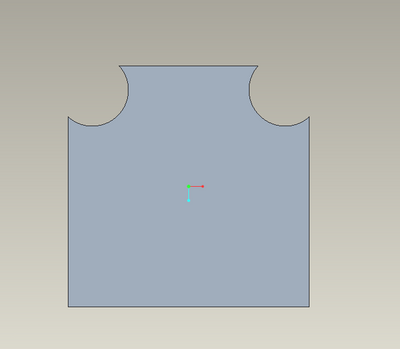

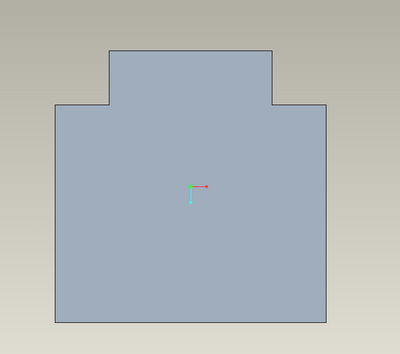

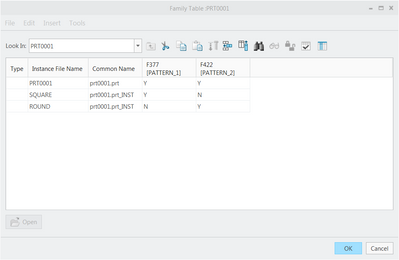

Here is an example of using a family table to implement what I think you are trying to do. It is a Creo 7 model with two instances one for a round corner cut and one for a square cut. Because I am not clear on the context of your design intent with this, I am not sure this would be the preferred method to solve the problem.

The location of the cuts is driven by a point pattern where the points are defined in sketch 1. Both the square and round cuts are patterned using the sketch and then a family table was created to include one instance for each shape cut. I think that using UDFs for the corner reliefs would probably be a good idea. If you define those udfs to locate and orient off of corner of the wall then you would be able to swap out the shape with UDFs and then pattern this one lead UDF using a scheme analogous to what you see in this model.

You do not have to use a sketch to define the pattern, I used as an example of how to define the location and orientation of the pattern members in a separate feature used to drive the pattern placement.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric