Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Standards holes - How to enable thru thread ho...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Standards holes - How to enable thru thread hole with up to surface?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Standards holes - How to enable thru thread hole with up to surface?

Hi,

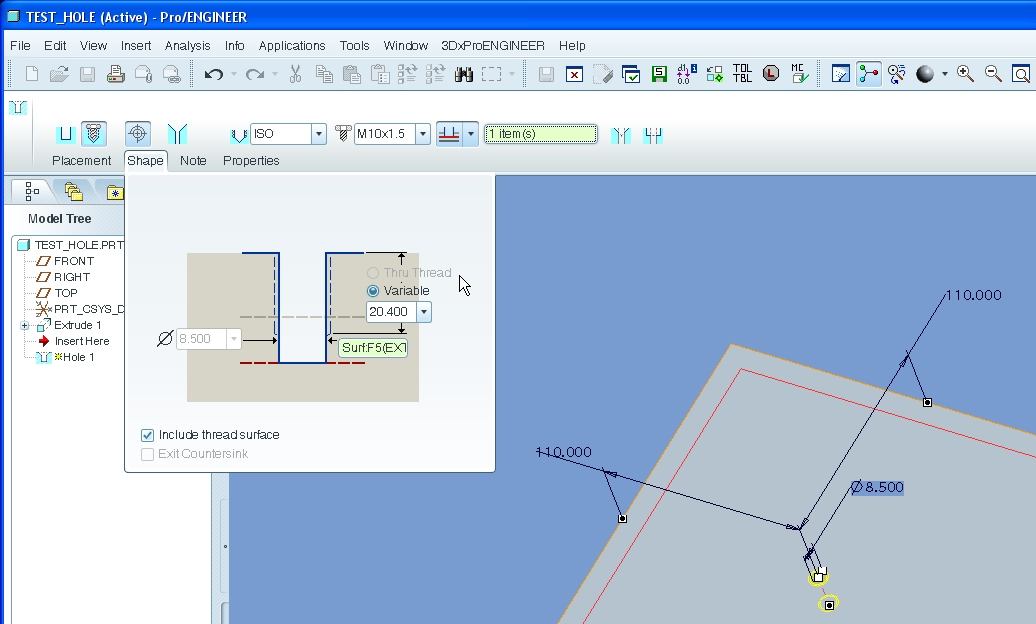

I'm trying to do a standard hole with ISO standard and I can't use Thru thread with up to surface. Can I change the hole configuration to be able to use this option?

I'm using Pro-engineer Wildfire 5.0.

Thanks!

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can set thru on the drill hole, first.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

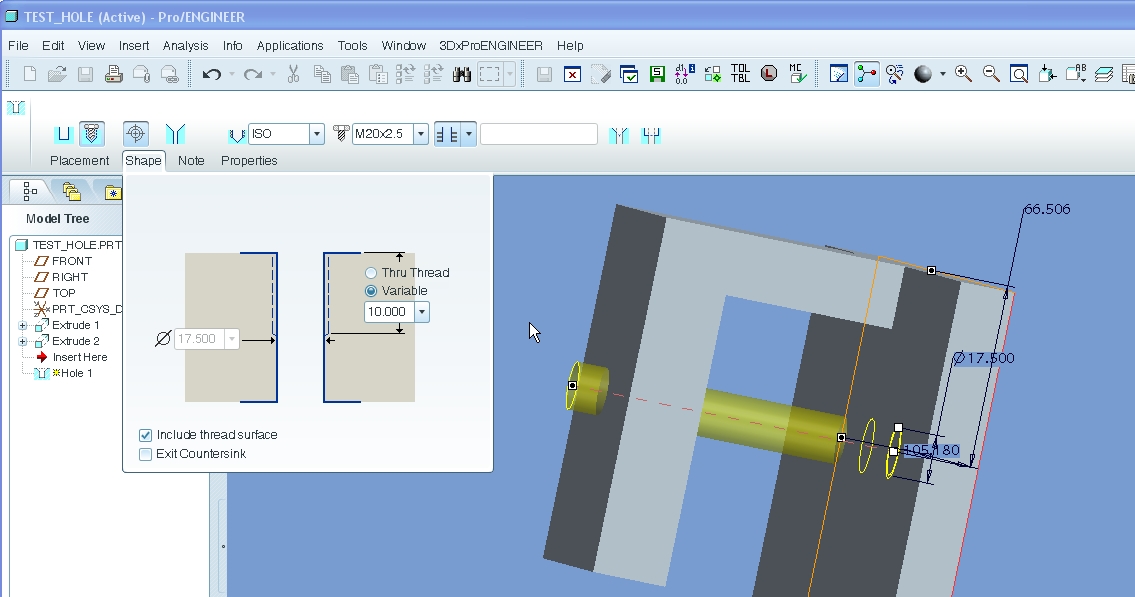

Thank you Matt, But I can not because on other parts I do not want to go through other surfaces. I want my hole on the first floor only (see picture). I don't want the situation on picture.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ah, ok well you can fake a couple ways, either type in a larger number on the thread depth, or almost the same way make it blind but deeper than the thickness of your plate.

Or put the hole in the model before you extrude the piece over it (probably the more correct way) then it stays parametric if you change you plate thickness later.

Or pick the other surface for direction (flip the hole).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Threads can't go deeper than the hole itself.

You can use feature relation to control thread depth.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks for your good idea, but I don't want to trick anything. I prefer make the good configuration in the standard table of pro-e.

Did anyone know how to unlock option?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ok, well, relations can get tricky.

What option do you want to unlock?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That was the premise of the question with which this began.

"Can I change the hole configuration to be able to use this option?"

I am not sure there is a configuration that is currently available to be unlocked to do this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Oh, right. Sorry, I didn't catch that the first, and also the second time. ![]()

There is no such config.pro option as far as I know.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There is no such option apparently but you don't have to trick the system to do this. There are several reliable ways to make the threads the same length as the thickness of the member but they all involve using relations. Typically you would create the feature and in subsequent actions, add the relation to the feature.

In the case of the example, however, you could reverse the face and use "through all" and "full thread" so it doesn't go through the other surface.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here d13 is a reference dimension in the body sketch.

D10 is the thread length dimension in the hole feature.

Setting d10 = d13 in the hole feature makes sure they track.

it would be helpful if the hole feature were to add a reference dimension for the hole depth when you use to-surface option.