Community Tip - Have a PTC product question you need answered fast? Chances are someone has asked it before. Learn about the community search. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Surfaces in Pro Engineer

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Surfaces in Pro Engineer

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Surfaces in Pro Engineer

Hi Guys

Can anyone help me sort out surfaces please.

I have a very simple model that I am using to learn this part.

All I want to do is change the flat surface to a slighly curved one.

Have attached what I have so far.

Best

F

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I suggest you start off with a surface free form. Then project a surface from the profile to intersect. Once trimmed and closed, you can solidify the feature.

You can also use sweeps, sweep blends, boundary blend, etc. if you need more control.

If you want to maintain a constant thickness along the edges, you have a bit more work to do.

We need a "blow up balloon" feature ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

HI

Am trying,but cannot get it to work for the time being.

What I want is to be able to have a curved surface 2mm at left and 2mm thick at right but 3mm in the centre.

Oh well, back to playing for an hour.

Best

F

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I guess that all depends on what you consider left and right ![]()

If all you want is a curve cut straight through the part, you start with a 4mm thick part and extrude a curved section to be 2mm and 3mm as you describe.

I was thinking a "bulge" in the center. That is a bit more work.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is what I was thinking... not completely happy with it, but it worked.

attached is a Creo 2.0 file

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi

Well I finally made something, its not what I wanted, not quite but will do.

Thanks very much for the help. Its a shame that we can't select a surface and pull it outwards or inwards

but no doubt one day...

Very best

F

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The attached model is still flat. I am still not sure what you are trying to achieve.

We can do a lot with surfaces but it is a challenge with core Creo. There are special surface modeler extensions for Creo. But that is for the ID guys. I bet it has something much closer to what you are looking for.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I normally don't have to much luck with Boundary Blends but I had it work on this part for some reason.

Have a look at the attached file and see if this is what you were after.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi

its ,prt but I can't open it.

Have been working on the main part thats 125mm deep.

Which version are you using?

Mine is wildfire 5.

Best

F

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yep, can't open it...IGES?

Is Creo 2 the upgrade to wildfire five?

I get confused by all the namings?

F

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You should be able to open a step file in WF5.

Yes, Creo is the latest.

IGES attached

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi

I got that one loaded ok, its actually very close to what I have.

I may try a slightly deeper version from 6mm just have to finish this part first.

Have tried Creo 2 and decided to stay with W5 though can't remember why, think is the Cam program

and letters, i.e text. Will get the latest demo and see.

Thanks again

F

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

solutions:

1. You can use the "warp" tool under the "editing" menu to manipulate existing geometry (bend, stretch, sculpt, etc..)

2. You can sketch the exact shape you want on the front surface and shoot it back, then extrude downward to cut away the exact shape you want from the top.

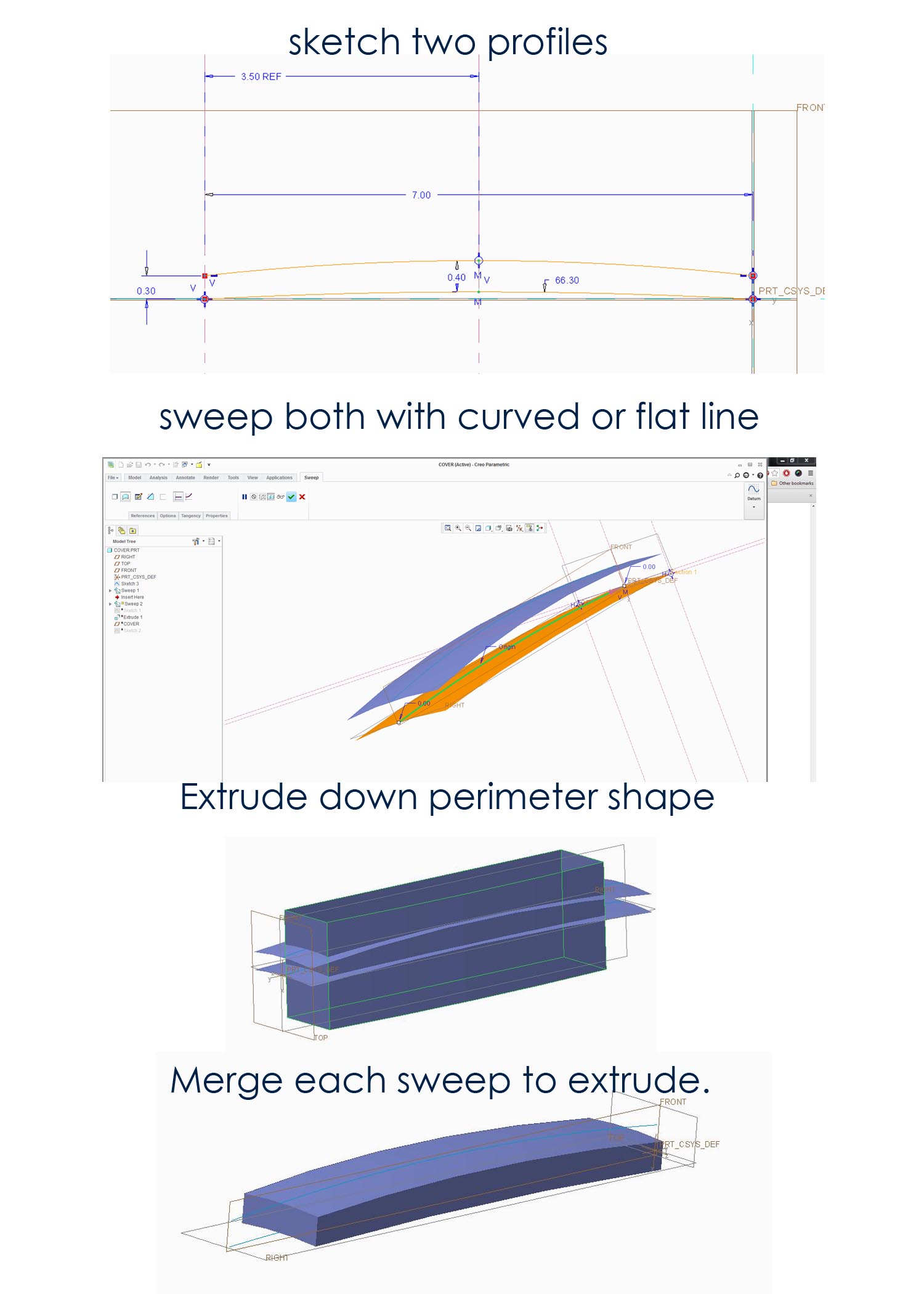

3. On the front plane, you can sketch two lines that have the correct distances between them (top and bottom of model), then sweep a curved surface for each. Then extrude downward the exact shape you want from the top, merge all and solidify.

#3 is what I would do, you have complete contol of everything, and it's easy.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hopefully you can zoom on this image. Didnt want to make it too large.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ian, the surface freeform works very much the same. I was challenging myself to maintain all the edges at the same thickness. This makes for a much more complex feature. And that complexity also translates to result.

I find that the warp feature still lacks a lot to be desired.

Does WF 5 even have Warp?

I like the second method much better. Controlled surfaces. I tried the VSS around the end rounds and I couldn't get it to do it as nice as the boundary blend.

This is all about style. What is the ID visualizing. This all helps to make the decision of how to tackle any one of these problems. In this case, i don't even know what it is, much less know what the intent is ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

WF does have warp. It was under the Edit drop down menu.

To maintain a constant thickness around the perimeter will be difficult, especially with the cookie cutter shape you have. Unless the constant thickness around the perimeter will be needed for functionality, it shouldnt be necessary. Aesthetically the eye will not differentiate between the tiny distance of 1mm. It would be a waste of time and there are no grounds for the struggle, as I can see.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Again, it is all about what you are truly envisioning. A lot of times, the edge "thickness' is a huge deal specially if it has to match up with a flat object or other curved surface. Of cource, shapes such as the convolutions really have a huge impact on the surface.

With the boundary blend, I used tangent to tame the inverse. Not following the convolutes minimized the edge distortion, but as an inlay, it will stand out like a sore thumb.