Community Tip - Did you know you can set a signature that will be added to all your posts? Set it here! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: assembly family

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

assembly family

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

assembly family

Hi,

I have a simple assembly containing 2 parts A & B.

I've made a family table for assembly and parts :

Assy1 : A1 & B1

Assy2 : A2 & B2

A have a variable number of holes, driven by it's family table

B have the sames holes, repeated by reference.

My problem is :

Assy generic : A_generic & B_generic (5 holes)

Assy2 : A2 & B2.

A2 got 6 holes in family table.

But B2 still repeat 5 holes of generic part.

How can I do B2 follows A2 ?

Thanks,

Dominique

Solved! Go to Solution.

- Labels:

-

Assembly Design

- Tags:

- family table

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Dominique,

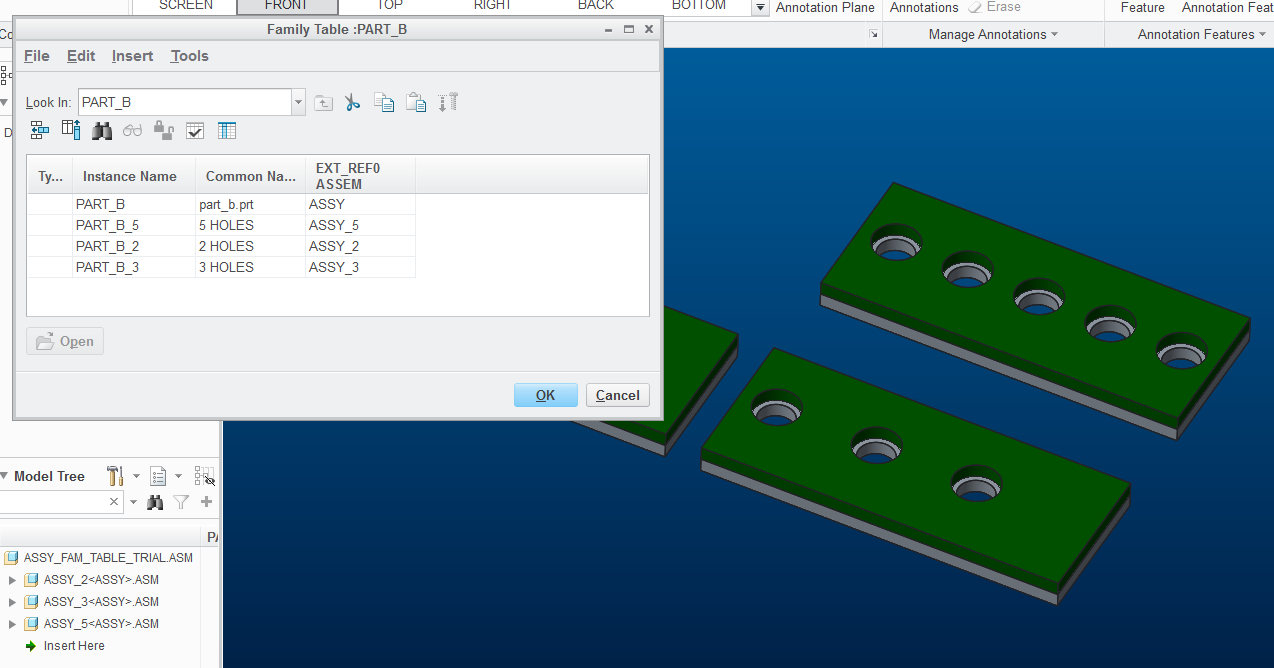

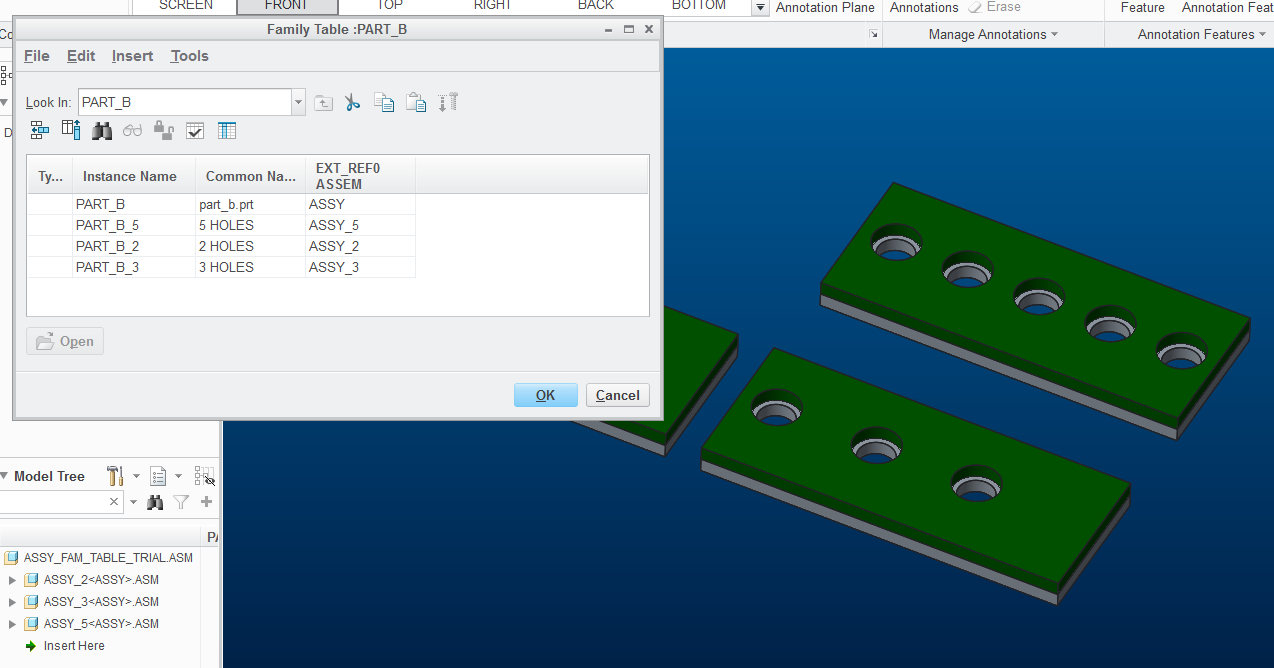

I tried to set up your situation and I am wondering what your family table for part "B" looks like. You have to let Creo know what reference model it uses when it regenerates the instance's reference pattern. You do this by setting up the reference model column in the family table:

As you can see, in this column you specify the assembly where the reference pattern gets created.

It seems work, although in my example, I had to manually update the reference pattern in new instances of part "B" by going through the "edit definition" cycle:

Help page is here:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Dominique,

Apprently you need to :

- Share some dimensions or parameters (eg number of holes in a pattern) through several parts.

- AND drive them from a family table of top assembly.

For me, in that case, the best way I could suggest is using parameters and relations.

(use skeleton in assembly could work but it would be more complicated to drive it throug a family table)

1- on each part create your pattern (start with two member repetition, it's enough but take care of using same dimensions on each to drive your pattern)

2- Create parameters in assembly level (let's say "number_of_holes" and "pitch")

3- create relations (working in assembly window)

(pick the parameters and dimensions name through the "relation" tool in creo).

add a relation in part A, pick the dimension or parameter to be driven on the part

then pick the assembly parameter in the param table

That's it

Now you can add the two assembly parameters in your family table

For example if you have a p7 parameter for your pattern and d12 pitch dimension in part A and P11 and D5 in part B you finally will have :

p7:0=number_of_holes:1 }

d12:0=pitch:1 }in part A

P11:2=number_of_holes:1 }

d5:2=pitch:1 }in part b

NOTICE THAT

0: ; :1 and :2 may vary depending on order and numer of parts you have in your assembly.

That's why you should create the relations beeing in asembly windows

Be careful : it is possible to modify the dimensions in each part in an independent way !

But as soon as you go back to assembly en regenerate it will go back to assembly parameters

Regards

Christian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks very much,

This process is working fine and solved my problem.

However, it would be fine to use repeat by reference.

I thought it would be possible, but it seams not.

It would be much nice and simple to have

a family table controled from number of hole on part A for repeated pattern

and a family table for part B, with repeated function by reference from part A.

Any idea ?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Dominique,

I tried to set up your situation and I am wondering what your family table for part "B" looks like. You have to let Creo know what reference model it uses when it regenerates the instance's reference pattern. You do this by setting up the reference model column in the family table:

As you can see, in this column you specify the assembly where the reference pattern gets created.

It seems work, although in my example, I had to manually update the reference pattern in new instances of part "B" by going through the "edit definition" cycle:

Help page is here:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Paul,

That's exactly what I wanted to do.

I didn't know "reference model" in family tables.

Thanks very much...