Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: bulk loading Elec Parts into Windchill

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

bulk loading Elec Parts into Windchill

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

bulk loading Elec Parts into Windchill

We are well established using Windchill PDMLink to manage MCAD files from Pro/E & Creo-Parametric 2.0 & 3.0, as well as SolidWorks v2012-v2015 with the WGM.

I am now in the process of testing the ECAD WGM, for use with Mentor Graphics VX1.1 (initially Design Capture & Expedition, and later DxDesigner), and I have done the basic setup on a test server so we can create Board and Schematic viewables, and generate a BoM from the Schematic. We have also got some OIRs for the ECAD Types.

When we generate the BoM, there are options to generate new Elec Parts for the PCB components if they don't exist in Windchill already, or else ignore them. If we generate new parts, then they are named and numbered according to the Elec Part OIR, which we have setup to put our company names & numbers on the parts that will be associated with the bare PCB and the built PCA. What we really want is to get the manufacturers' part numbers as the Windchill Elec Part name & number, for all catalogue parts.

So what I think we need to do is to take our existing PCBCAD component library, export it as an Excel file, edit that file to only have columns for the Name, Number, Description, and maybe one or two other company attributes, then save it as a CSV file. I believe this can be imported by some method into a PDMLink Library to make all the Elec Parts in a batch process. Can anyone tell me if this is the right thing to do, and how to do it ?

Thanks in advance,

Nick

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

Routed Syst. Design

- Tags:

- group discussion

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

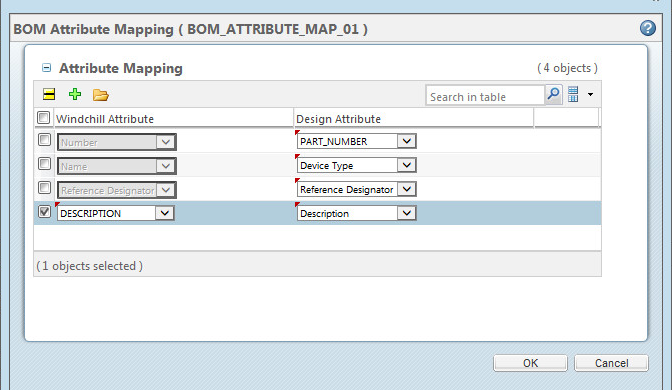

Nick, I think what you want to do is to change your BOM Attribute mapping to have the values from the Manufacturer's Part Number to be populated as the Elec Part name & number. You may need to change how the BOM is being generated from the schematic. I don't know the Mentor toolchain all that well, but there should be a template or set-up area where you select which fields from the schematic are included in the BOM. You would want to include the Manufacturer's Part Number in the BOM that gets generated for the import data process. Then, once that's in there, the BOM Attribute Map (BAM) would do the translation from Manufacturer's Part Number to WC Part Name and WC Part Number.

If you don't do that, then when you bring the parts in, they still won't match what you would have done in the CSV file. Plus, you would have to constantly be running a manual sync between the Mentor library and WC.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Patrick,

We have setup a BOM Attribute mapping, and found out how to add more rows to that table in order to map Global Attributes (which are inherited by the ECAD Document type as a sub-type of CAD Documents… which we already setup for MCAD), along with the additional configuration as per CS53983.

The PCBCAD Design Attribute "PART_NUMBER" does already have the value of the Manufacturers' Part Number in each component instance (and we will change Windchill Name to be the same the next time we edit this mapping file).

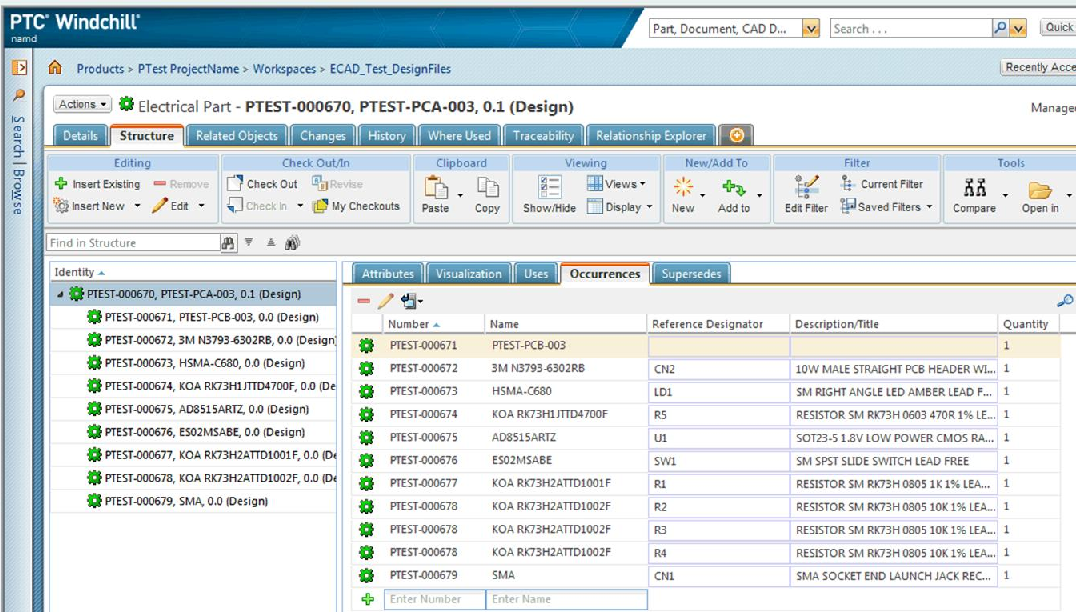

When we use this to generate a BOM from a Schematic, we get the following result - and the problem we have with this is that the new Elec Parts made by the generate BOM function have been made with new Numbers based on our Elec Part OIR as they were not already present in Windchill, rather than the Manufacturers' Part Numbers as set by the BOM Attribute Mapping. I think this indicates that the Elec Part OIR is overriding the BOM Attribute Mapping.

Our Elec Part OIR is set to use a numbering scheme that will be appropriate for the new Parts needed to go with PCB's and PCBA's, ie. when we build and associate Parts with the ECAD Documents for Boards and Schematics.

My understanding (and hope) is that if we have already loaded the Elec Parts into a Windchill Library with the correct Name & Number, then the Generate BOM function will spot that they exist already and not create new Elec Parts using the OIR (which will also store them in the active Product repository), but instead make links to the existing items in the Library.

The crux of this question is how to use Manufacturers' Part Numbers for components on PCBs but our own Part numbers for the Boards and Board-Assemblies that we design.

Nick

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ahh, now I follow fully. I missed that the OIR was giving you numbers that weren't the Manufacturer's PN, but that makes sense. Yes, if they exist in WC, then it will automatically use the ones that are there. That's what I'm doing. As I'm guessing you know, PTC has a tie-in gateway with Cadence ADW (or EDM depending on what version you are talking about) for library sync, but they do not have a similar option for Mentor tool users.

I am using Cadence and have the gateway configured, so I know a little about what's going on in the background. Maybe that can help a little.

Basically what happens is out of Cadence, I get an XML file with all the information from the library. Then, there's an Infoengine task that runs and takes the XML file and creates new parts or updates existing parts and maps the metadata fields from the XML export to attributes in Windchill. The gateway actually has a method to send parts and metadata back to Cadence, if you want, but I'm not using that piece of the tool.

So, going back to your original question. Yes, if you can create a copy of everything in your ECAD library in Windchill, then an ECAD design should use the same parts, if the Part Numbers match. Now, how to do that without the gateway, I'm not really sure.

One word of caution, and I'm not sure how you deal with this at your company or not. But, Manufacturer's Part Numbers do change. It's not common, but for instance in my library, I have around 14,000 active parts, and I get a handful of PCN from the Manufacturer's every month with part number changes. Depending on the size of your library, it can be a big effort to make sure they stay synced. And don't even think about it if we go through another RoHS regulation (probably 60% of our part numbers changed due to RoHS when that happened). Plus, in our system, we're not allowed to change Part Numbers in Windchill once they have been released. The one-time import is one hurdle, but the maintenance and even just adding new parts going forward is something to make sure you have captured in your process. Just food for thought.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Patrick,

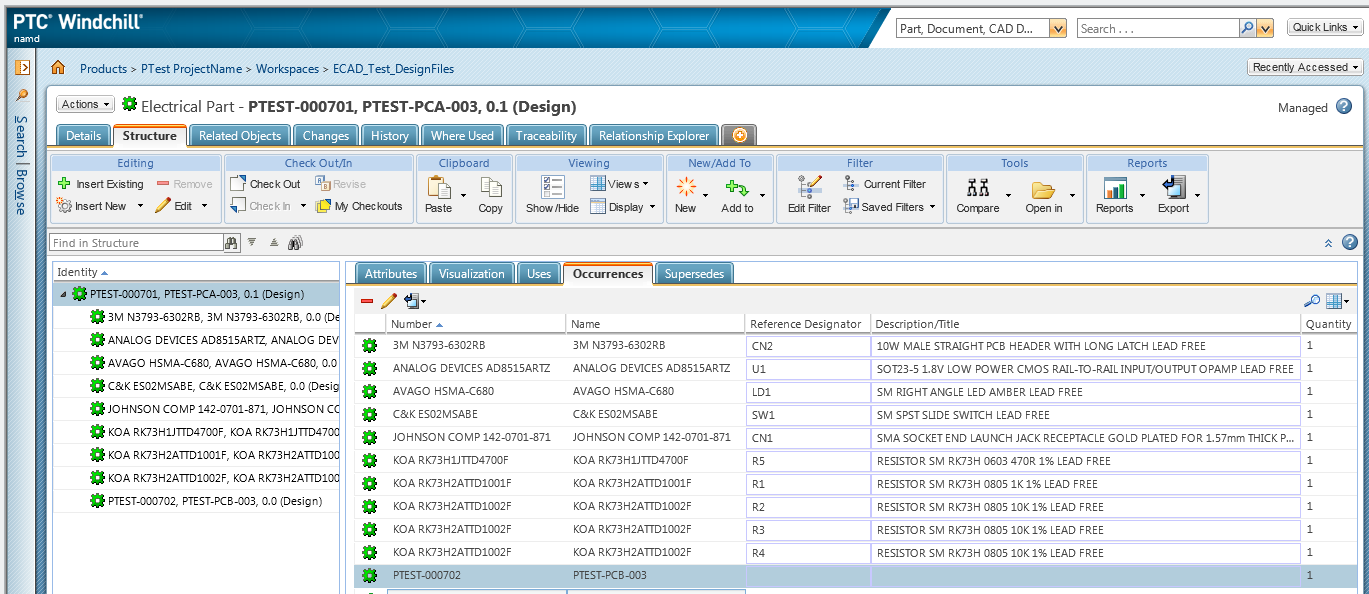

We have now found out about the alternative, simpler method to bulk import Parts - see the WHC and search for "How to Import Data from Excel".

There are some example Excel files in a folder on the server, and a Workspace Action to 'download an importable spreadsheet' that can be used on any example Part. It took a couple of test runs to get the formatting just right, and what's really nice about it is that it can handle incremental updates to add new parts or update attribute values (and I am told this process can even be automated with a listener process that looks out for updates to the imported file...). I expect that a correction to a part name or number will still require a rename action, but they should be very rare.

We have tried using this method for a few parts, including a couple of our own IBA's, and then generated a new BOM during an ECAD Check In, using our own BOM Attribute Map and it worked as required, ie,

- we got the pair of new ECAD Docs for Board & Schematic, together with Electrical Parts for Board & Assembly in the Product area, all named using our OIRs, and

- we have the Electrical Parts for existing components, named and numbered with manufacturers' p/n's in our ECAD Library, parts folder(s).

My next step with this topic will be to work my way up to trying the full 28,000 parts, but at least this method allows them to be done in batches and directed to be stored in sub-folders if/as required for easier browsing.

Thanks for the help,

Nick