Community Tip - Learn all about the Community Ranking System, a fun gamification element of the PTC Community. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: drilling issues

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

drilling issues

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

drilling issues

Has anyone seen this problem?

I have a part with 12 through hole and 12 counterbores on the holes. When I drill the through holes everyting works fine, But when I counter bore the holes I only get half of them. Very frustrating! No matter how I try and select them it will only cut the six holes.

After searching the knowledge base I see there is a SPR (1984609) up there addressing this issue. I will have to wait for M110 for this to get fixed.

I would think PTC could get these basic machining functions fixed and out to customers a little sooner then having to wait until the next rev. cycle on October 21.

I am running Creo/Wildfire5 M100 by the way

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You could try these two option if you haven't already. Select all 12 holes and the start plane. For the depth plane try either of these two set the depth at a blind depth or create a datum plane that is specific to the hole set at the depth you require. We have seen similar issues and have been able to get around it with these two options in some instances.

And I agree that they should be able to handle basic machining without issue. The fact that we have to wait so long for a resolution to a problem only adds to our frustration.

Good luck

Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is a bad issue! Have you tried defining your counter bore sequence for three holes and then creating a refrence based pattern?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Nick,

Thanks for the fast reply.

That is what I had to do. Create a pattern of the first set.

The holes were created using a mirror not sure if thats the issue or not but it is definately a bug in the software.

Best Regards,

Steve

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You could try these two option if you haven't already. Select all 12 holes and the start plane. For the depth plane try either of these two set the depth at a blind depth or create a datum plane that is specific to the hole set at the depth you require. We have seen similar issues and have been able to get around it with these two options in some instances.

And I agree that they should be able to handle basic machining without issue. The fact that we have to wait so long for a resolution to a problem only adds to our frustration.

Good luck

Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think there needs to be more resources allocated to the manufactuing development team. I think there is posative movement in that direction and I hope to see new innovations sooner rather than later.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This has started me thinking... How can we help drive improvements? Should we open a whole bunch of enhancement requests, report bugs, or post ideas on this board? What do you guys think would help?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Enhancement request seem to fall into a black hole to never be seem or heard from again. I know that PTC has been working on a new mechanism for enhancements, but this seems to be progressing at a snails pace. As it sits right now, I wouldn't waste the time to file one.

It is always a good idea to report any bugs that you find. The problem that I have ran into lately, at least for the last 6 to 9 months, is that all manufacturing support has been shipped off shore. It now seems to take days to get an SPR filed for an issue and them months to see a resolution.

Another method is to get involved with the Technical Committees.

Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I hope that you are right. Otherwise, in my opinion, there will be an exodus in customers that rely on the manufacturing tools.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'm pretty sure a large majority of companies have already migrated to other packages out of frustration and lack of development.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Nick I agree,

I think the manufacturing software is some of the best out there. I am not sure whether PTC thinks it's worth all the time and money supporting it though?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

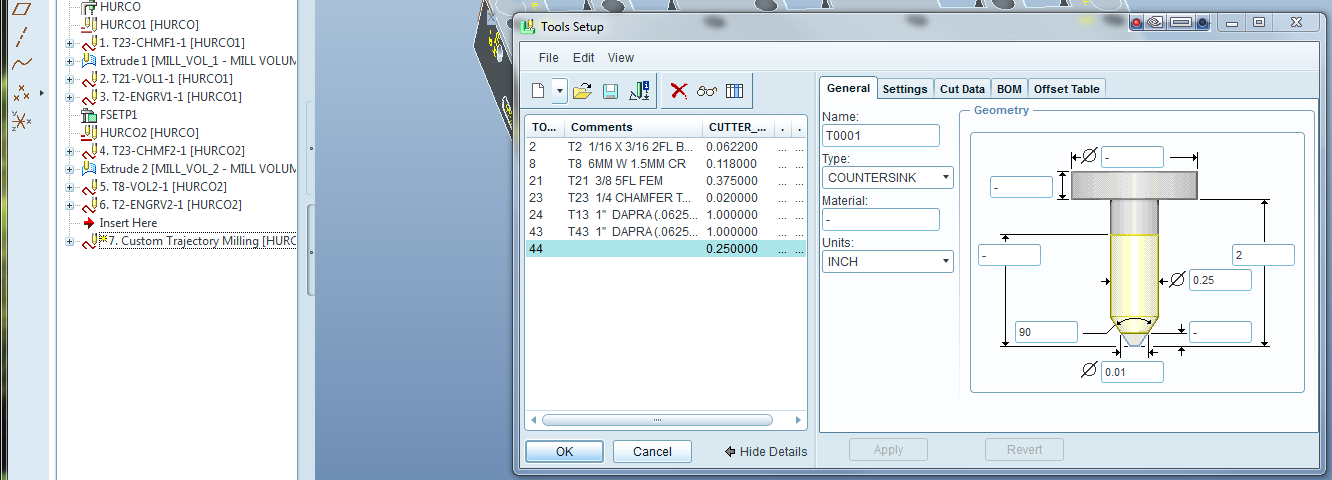

Thing that I find frustrating that I would think would be simple fixes like Being able to counter sink holes and then chamfer pockets or walls with the same tool.

Can't be done with Pro/Man you need 2 different tools cluttering your tool manager even though the tool geometry is the same.

Helical milling holes is another. It can be done, But not without a bunch of hoop jumping.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How are you milling your chamfers? I just use a custom trajectory which does allow a countersink tool to be used

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is the method that we use also.

Either of you have a suggestion to get a roughing and or re-roughing to stay in the cut without jumping around like a kangaroo on steroids? We spend more time with the tool retracting and moving around to a new start location than actually making chips. Extremely frustrating for both the programmers and operators.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is a common issue for me as well most of the parts I program are 3 feet long and 50 -60% of the time my tools are traversing in the air. I know that because vericut tells me now ![]() I put in volume roughing where i can and sometimes I get creative with my mill windows but still the tool moves around alot.

I put in volume roughing where i can and sometimes I get creative with my mill windows but still the tool moves around alot.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We utilize Volume Milling for probably 75% of our programming. The concern that I have though is I keep hearing how PTC is looking to do away with it. They no longer want to support the code that has been around for so long. Roughing sequence were supposed to replace it, but we can't afford all the wasted machine time we see when using a Roughing sequence. That is why in Creo 1.0 the menu manager still pops up for Volume Milling.

We also rely on Vericut quite heavily.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Nick,

again you are correct you can chamfer with a countersink but you cannot countersink with a chamfer tool so I guess I need to change how I do my chamfering

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Are you running WF5 M100? It lets me pick that tool type for custom trajectory.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes Nick WF5 M100

what I was saying is that I can use custom trajectory with a countersink but you cannot countersink a hole with a chamfer tool. it gives you the tool type not valid error message. Sorry for the confusion. it doesn't matter since you just showed me I can use a countersink for chamfering.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Brian,

Nick posted a side milling example on here a while ago. It works great. I use it when ever I can. it works like trochoidal milling.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Brian,

I know what you mean I use mill volume a lot on surfaces where i can trim to them. I works great for that. do you use a stand alone version of Vericut ? I know the pro version is very limited in it's ability. the last place I worked I had a full version and the cut optimization is nice, but expensive.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I just have the one that came with WF5. looked at switching to NC simul but couldnt justify the costs. that brings up another question when is PTC going to develope there on simulation software? And one that ties in with a stock management feature because material removal is not really that great.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Another Question to everyone.

Which do you trust more gougecheck or vericut?

I do not trust vericut. and use gouge check for all my tool path checking. vericut is just a visual check of tool path and hole work because gouge check doesn't do holes. but for tight tolerance surfacing I like gouge check.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I agree with that. However gouge check does not catch tool shank interferance where as vericut does. I use both usually at the same time to limit any errors.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We utilize a stand alone seats of Vericut. The shank interference is the main reason. We do a fairly sizable amount of undercutting with side milling tools.

We looked at the optimization in Vericut, but were told by CG Tech that we would need to rerun the simulation after it was optimized. This eliminated any savings that we would see. All our parts are one of's.

A quality integrated stock removal and or simulation tool is long overdue. Hopefully we will see one sometime soon.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I wonder if Jose Coronado reads any of these posts?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I know that other PM do. I can't recall if I have ever seen Jose on here.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Brian,Nick,

I wouldn't hold my breath while waiting for PTC to do any verification software.

I doubt Jose reads any of this but I am sure some of the techs do.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've learnt that I wouldn't hold my breathe waiting on PTC for anything. I would have keeled over long ago.

The problem is that Jose can only work within the budget he is provided. It is the powers that be above him that control the purse strings. I know by the content at the user conference and the marketing that Windchill is the baby. Manufacturing is something that they keep around but don't really apply a great deal of development dollars too. Unlike other CAM packages that simply focus on CAM, PTC is always looking at where they get the most bang for their buck. They seem to forget that we are maintenance paying customers also.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We demand more money for Jose and his team! ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Brian I agree,

it's obvious where the money is. but for small companies like the one I work for it's not much fun listening to all the hype about windchill and such. it's like if you don't have 10 seat of pro and windchill you get shoved off to the side to a var like tristar and a few others for tech support. Not that there is anything wrong with that. It can be a benefit sometimes. A little more personal than going to the ptc off shore support.