Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: flexibilty question

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

flexibilty question

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

flexibilty question

hello! I have a model of an electrical cable coming off an assembly in creo 4.0, that is modeled straight (as a sweep in a straight line). Is it possible to make this cable "flexible" and orient/route it in many different configurations in both the assembly and the drawings of this part? any help is greatly appreciated!

- Labels:

-

Flexible Modeling

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can "flex" any of the dimensions as long as the new values are valid for the model.

You can also suppress and unsuppress features of the model. This means you can create many different routings and suppress the "extra" routings in the model. Then in the assembly you can suppress the default routing and unsuppress the desired routing.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Short answer: No. Longer answer: Maybe, it depends. Yes you can have a bunch of routings and suppress them at the assy level with flexibility, simplified reps (which just creates a family table in the background), or family tables, but that's a nightmare, especially if there are more than a couple routings, AND you'd need to turn off at least one of the connectors at the connector assy level, so, now you have to have 2 layers of flexibility. TOTAL nightmare. So, what I did that works and is as simple as I could make it, is to use a coordinate system for the mating face of both connectors at the cable assembly level, with predefined flexible dims for X, Y, Z translation, and X, Y, Z rotation. Route the wires at the cable assembly level (not the assy level that the cable is installed at), and then at the assembly level the cable is used in just input the numbers needed to mate the connector coordinate systems to the connector coordinate systems at the next level assy. BUT, some of the wire routings may or will fail or overlap geometry depending on how radical a departure from the original cable routing the upper assy routing is (twists are the worst). Also, there is no way to make the routing the proper length, so, it may look a little funny. I did this back in maybe 2007, so, maybe the cabling module is good for this now, It wasn't back then and we didn't have it anyway so I had to do it manually. For the connectors, I made the CS positive Z facing the direction of the MALE CONDUCTIVE contact for pin 1, and reversed that for the FEMALE CONDUCTIVE contact of receptacle 1. Some connectors LOOK male because of the way they engage the other connector, but I went by the electrical contact. This way constraining the first end of the cable assy is easy, CS to CS, done. Consistentcy is the key, make sure that whatever standard you make for connectors, applies to ALL the connectors.

It's a challenge for sure. I enjoyed it, but some might find it a PITA. Best of luck!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

okay, i appreciate the response @Patriot_1776 but then how would you modify the routing of the cable on the fly? Would you be able to make the cable pass through a gromet in a panel?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That is why I said "maybe". If it's just a routing that is simple, you can get by with what I mentioned. If you're "threading the needle" around standoff and thru grommets, then no. What I would do in that case, is create a cable assembly for that routing. So, you have an assembly that uses 1 or more cables and its filename is: "1234.asm", and your cable filename is: "5678.asm", then make a cable assy 1234_5678_route-01 (-02, -03 etc. for different routings of the same cable). As mentioned, I established a system of connector constraints. So, create the cable routing assy, insert the first connector at the default CS orientation, then constrain that assy at the upper level target assy where the cables are used. Then make that particular cable routing assy "Active", and add the second connector to that cable assy but using the mating connector CS at the target upper level assy. This creates a parent/child relationship, but it is pretty much unavoidable unless you're doing top-down design using a skeleton or master model. While still in the cable routing assembly, now run your wire routings pin to pin between the 2 (or more) connectors. This cable is now parametric (unless the routings fail) so if the location of either connector or grommet moves, the routing will change. Since you're never using this particular routing anywhere else, (another assy or dwg), the affects of the parent/child relationship are not a big deal. If you HAVE the cabling module, I'd use that, if not, you can do it manually as I mentioned.

Either way, it's either a challenge (as I took it), or a PITA, it just depends on your outlook on it. Best of luck, and post pics of the result.

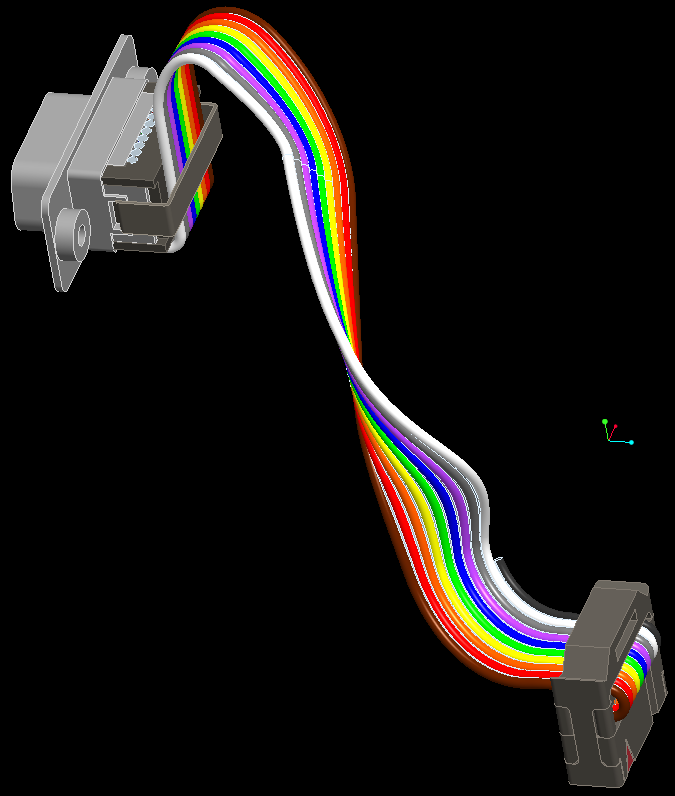

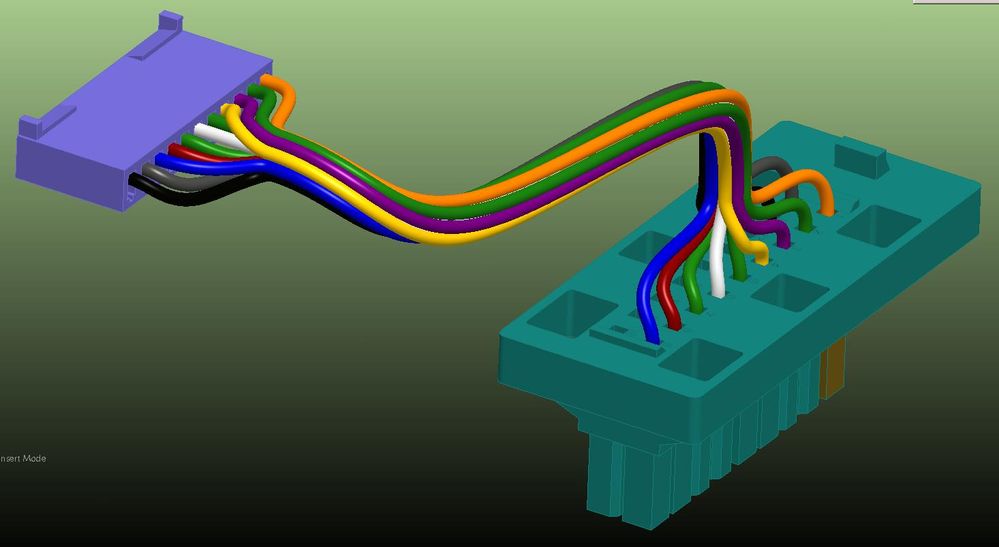

Here's a couple I did years ago, the ribbon cable with 180deg twist done in maybe 2007, the other one done in maybe 2013.:

Note, if you do a twist like that ribbon cable (or even just wires, there MIGHT (WILL be with ribbon cables) be an issue with the cross section of the wires being incorrect unless you get the trajectory right.