Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: how do I make inner acme/trapezoidal thread?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

how do I make inner acme/trapezoidal thread?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

how do I make inner acme/trapezoidal thread?

I found a few videos on how to model outer threads, not inner threads (nuts). I'm struggling to get all the dimensions correct for a Tr16x4 nut.

I printed a prototype already. The hole size seems accurate, and the trapezoidal screw threads in initially, but it gets stuck halfway through. Can you help me figure out what I'm doing wrong?

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

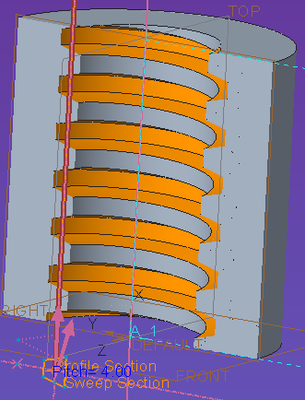

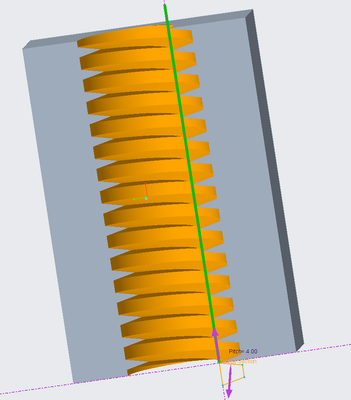

Those threads do not look correct. Should look more like this:

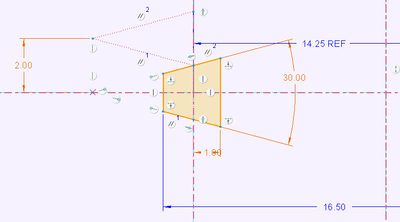

This is how I created it using the PD to control it. The pitch diameter is increased .25 from nominal for clearance.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Female threads are modeled using a helical sweep typically in the same manner as a male thread profile. If you feel that you have accurate geometry in your CAD model and the thread is not engaging correctly then it is likely an issue with the 3D printer tolerances.

"I'm struggling to get all the dimensions correct for a Tr16x4 nut."

Which dimensions are you struggling to implement in Creo? I presume this would be in the sketch used in a helical sweep for the thread profile.

I am not able to open a Creo 10 model (I have Creo 9 installed). If you have an issue with the sketch section of the thread in the helical sweep, then post an image of the problematic sketch geometry. Other than the sketch there is also the pitch dimension used in the helical sweep. I would also suggest that you disclose what reference material you are using to guide your design of the thread (i.e. Machinery Handbook or other reference).

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

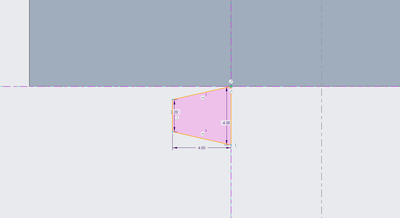

yes here's the sketch for the helical sweep. this is what I have drawn, pitch is set at 4mm

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Your inquiry is still not clear to me. Do you have a thread specification that you are having difficulty modeling in Creo? Is the issue that you built an accurate model in Creo and are asking why the 3D printed parts are not meshing well? Threads in metal parts are made using processes that generally hold much tighter tolerances than you will get on any 3D printer.

Here is an online calculator for this type of metric trapezoidal thread. Use the calculator (at your own risk) to generate the dimensions for your threads and then check them against your Creo model.

https://www.threadspecification.com/tr/

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

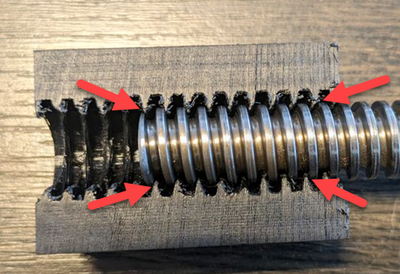

I printed the black block in which that thread is supposed to go. it screws in nicely at the beginning on both end but gets stuck in the middle. I tried it with multiple blocks and checked my printer settings but the dimensions are correct. its just the dimensions of the helical sweep that im doing in creo that im unsure about. Im thinking thats where the problem lies but I dont know what to adjust.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would put money on it being a 3D print issue and not a Creo issue. I doubt if an FDM printer is capable of maintaining the tolerances and geometry required for your purchased lead screw to work correctly with the 3D printed block. I doubt the screw threads are even on axis within spec through that printed block.

A lead screw is typically used where there is some requirement for precision, so it seems incongruous to use one mated to an FDM printed thread.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Those threads do not look correct. Should look more like this:

This is how I created it using the PD to control it. The pitch diameter is increased .25 from nominal for clearance.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes this is what I was doing wrong, thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Make sure the thread profile is normal to the axis, not the trajectory.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've printed acme threads before. both male/female. I think I added "extra room" for the threads.

Cut your block in half (or take 1/4 out, expose the threads. then you can see where the problem is, maybe.

I'm thinking you just need a little clearance

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I do need more clearance. what should I adjust here?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think this looks like a pitch problem. It looks like your OD and ID is good, so i'm thinking it's not scaling.

But your threads are touching on both opposite sides. To me that is your binding and I'm thinking the pitch is wrong.

Verify your threaded lead screw is the pitch you think it is. I would physically measure threads per inch or whatever it is in metric on both pieces.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I guess my major question is why do this anyway? Print the part solid or near solid, with a hole in it the minor diameter of the threads, and CAREFULLY thread it with a tap. You can help by heating the tap up (not red hot but almost to the melting temp pf the plastic). This is an ACME thread, so, it'll definitely be more difficult than a regular thread, so you'll need it in a vice on a precision drill stand, and make sure the tap isn't too hot, and that you "feel" the pitch of the thread. Don't try and do it all at one, "peck" at it, tapping a little, backing out, repeat as needed. Once a couple threads are established it will guide itself as to pitch, the first thread or 2 are the tough ones.

Best of luck!