miter cut / corner releif of a chane flange bend

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

miter cut / corner releif of a chane flange bend

Hi, trying to understand how to get what I want. While I have options, nothing seem to change when various option are chosen..

1) I made a chain flange to have a nice flange about the 2 sides of an 'L' shape.

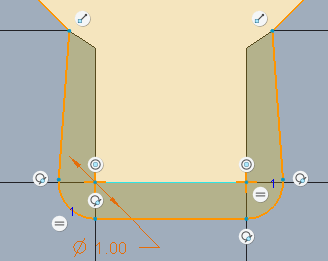

It then makes the flange, and creates both a corner relief and a mitered cut. If I choose "closed" I get a closed off corner, which is what I believe I want. But it does give a bit of a weird shape on the flat pattern.

It also gives a gap. The end of the gap isn't really 'tangent' to the inside of the corner bend radius, which I would have expected.

Now, if I have an open corner, the gap creates a little 'tooth' on each side of the mating mitered flange edges. (See mitered.jpg) I then need to do an unbend / bend back with an extrusion cut to remove these "bits", and get a simple 45°cuts on the flat pattern.. (See miter 2 & miter 3.jpg..)

2) while I have options to vary the corner relief, nothing seems to change with options chosen. So, no idea what these do or control.

I feel I am stuck with whatever Creo is programmed to spit out..

any help or direction to a better / concise explanation on how / what these options control?

dunno really how else to explain it..

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you change the 1.1*Thickness to 0 the nubs will be removed leaving only the small gap.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, thanks.

No. The smallest I can enter the gap is 0.0008", I still get the nubs. (although teeny tiny!)

Unless I missed something else..

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have always found the sheetmetal reliefs a bit lacking in Creo.

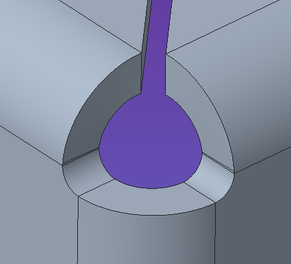

The small nubs are Creo trying to keep the edge perpendicular to the surface as it goes around the corner. The only way to create a "clean" relief is to create it yourself.

Unless you need a tight corner fit, to reduce stress concentrations, I would suggest this type of relief cut:

There is always more to learn in Creo.