Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- multiple thickness shells

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

multiple thickness shells

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

multiple thickness shells

Hi,

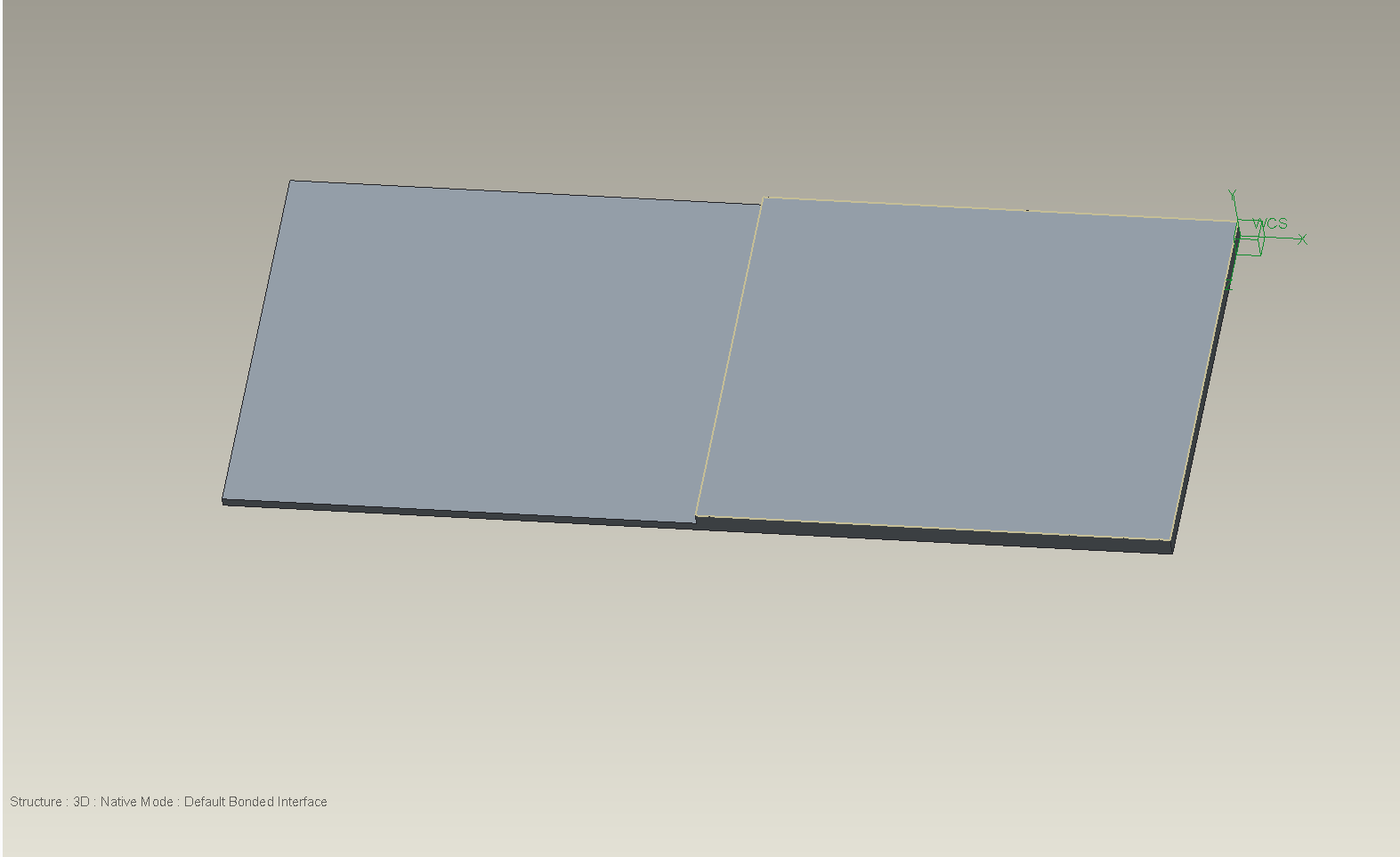

how can you create mid surface shell pairs in a part that has 2 different thicknesses?

Solved! Go to Solution.

- Labels:

-

Surfacing

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

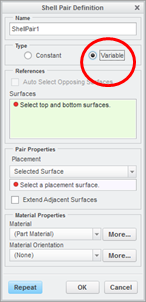

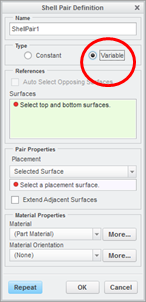

You need to use 'variable' in the shell pair definition

As there can be no common mid-surface you need to define where the mid-surface is. Note 'select placement surface'. This is an approximation and actual mid-surfaces will be moved so that they align. This will change the stiffness of the structure.

The process works in a similar way if your plates are a single part or an assy of two plates.

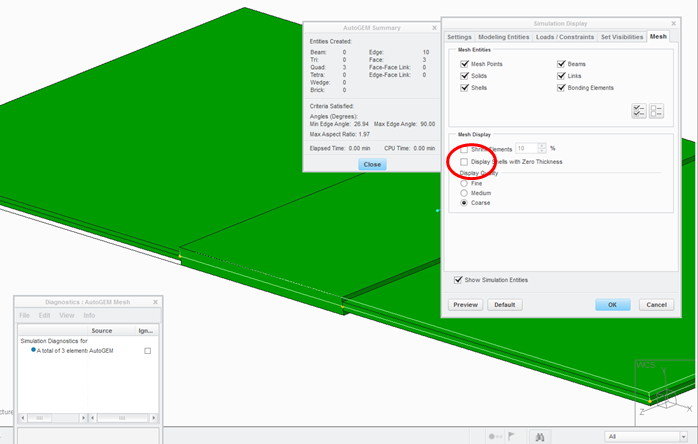

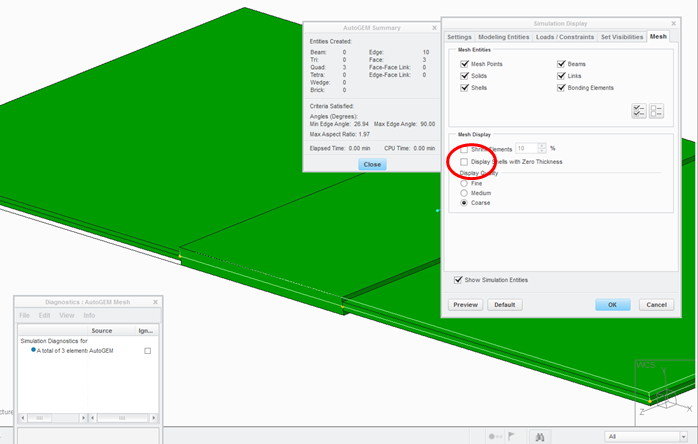

When you mesh, switch off 'display shells with zero thickness' and you will see what the numerical model will be ...

Regards

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

You need to use 'variable' in the shell pair definition

As there can be no common mid-surface you need to define where the mid-surface is. Note 'select placement surface'. This is an approximation and actual mid-surfaces will be moved so that they align. This will change the stiffness of the structure.

The process works in a similar way if your plates are a single part or an assy of two plates.

When you mesh, switch off 'display shells with zero thickness' and you will see what the numerical model will be ...

Regards

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

thx!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

I have the same problem but in CREO Parametric. Is there a possibility to solve it?

Regards