Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- slider mechanism with no axes

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

slider mechanism with no axes

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

slider mechanism with no axes

Our mechanical assemblies will always need clearance for sliding parts so for the last two decades we have modeled these assemblies with offset surfaces.

The has worked well. This method of assembly is a fast, accurate, and robust way to locate components or sub-assemblies.

So the reason I’m venting here is that it would appear that this method is simply not available if the modeler uses the slider constraints.

Then the modeler is required to create some offset axis (or edge ) strictly for the damn slider functionality.

Then the user or some future user must play diagnostician and perform the damn detective work if a component or assembly is changed so the mysterious damn axis (or edge, like you said) fails to align and causes the assembly to fail.

Do remember we’re talking about the design phase here. The components and assemblies are changing (being designed)

To require the user to create an arbitrary axis (yes, or edge) is an obvious example of lazy development on the part of PTC.

The slider functionality should be easy and robust. I couldn’t imagine a much better and simpler scenario- the user defines two offset surfaces. This completely locates the part in all modes of movement except translation in one axis (get it? slider) what could be simpler. Of course then the user would define travel in the free direction (or not)

I’m sure PTC will address this issue at such a time that it can be reasonably determined that hell has frozen over.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

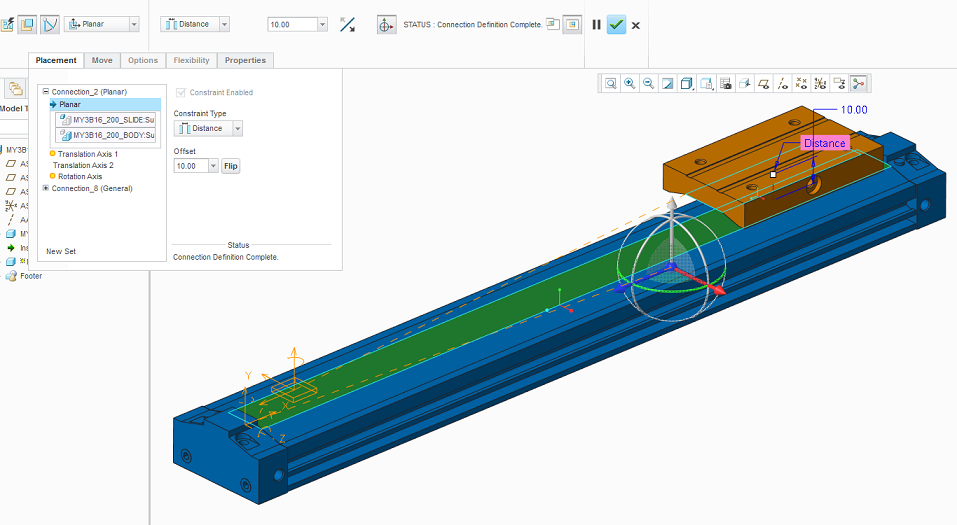

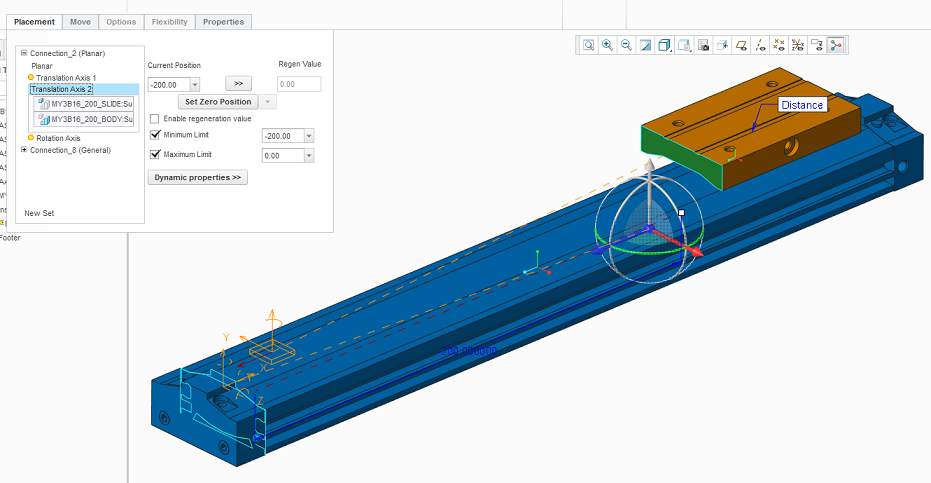

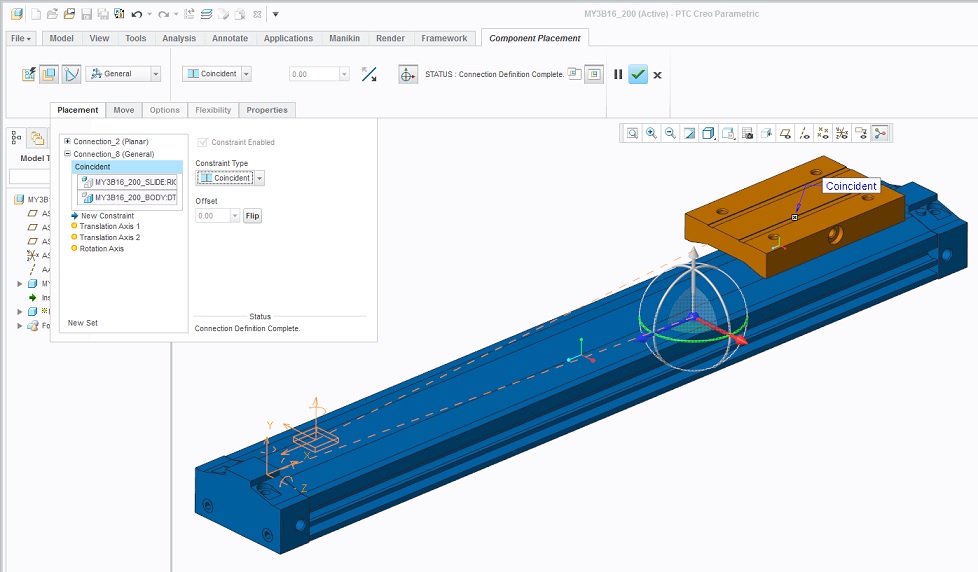

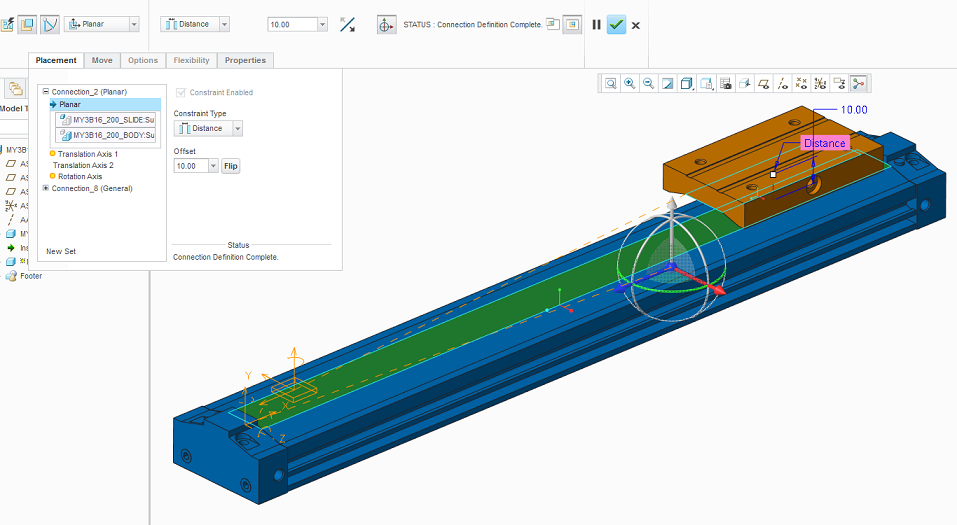

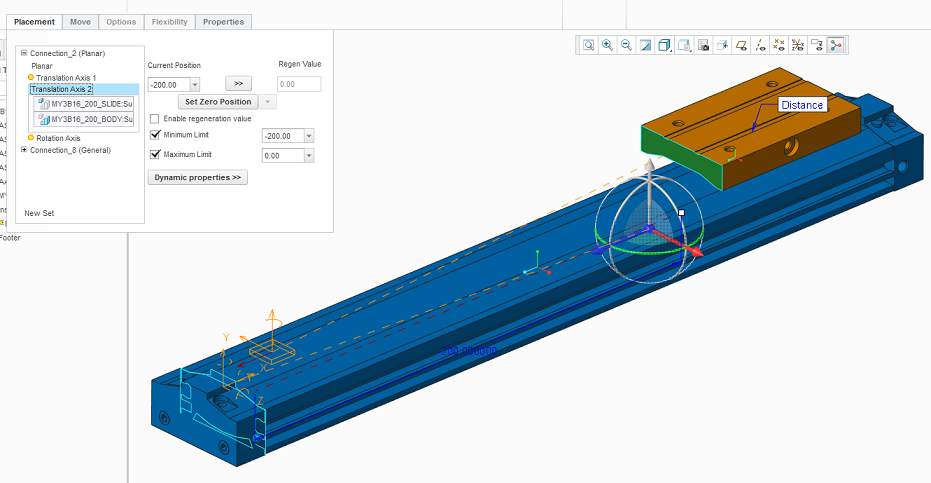

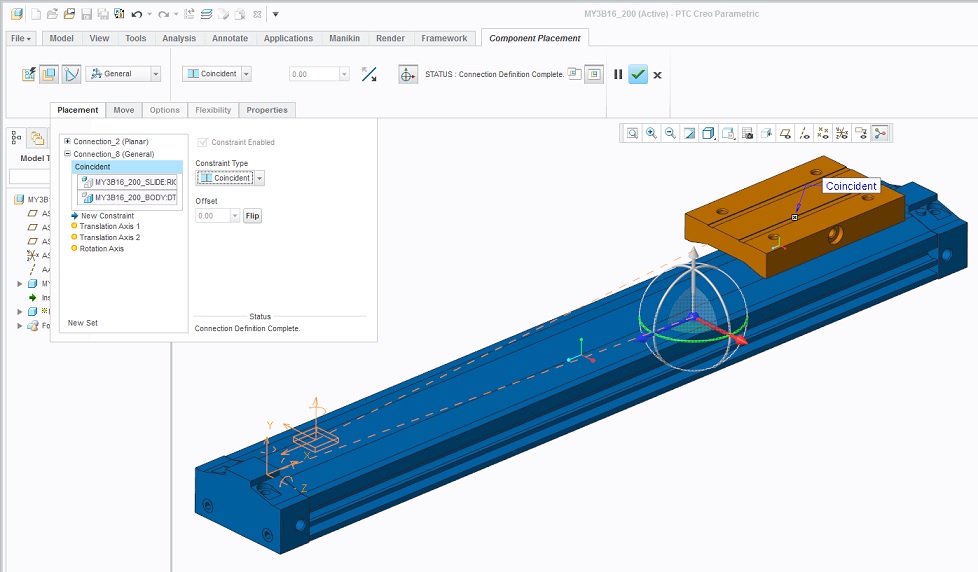

I use planer in one set and general in another set to fix sliding mechanisms. If you see in the second image you will see one of the arrows of the planer mechanism icon is highlighted in red. Is this the thing you were after?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I use planer in one set and general in another set to fix sliding mechanisms. If you see in the second image you will see one of the arrows of the planer mechanism icon is highlighted in red. Is this the thing you were after?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Miles,

You were first I guess that's a correct answer.

I had forgotten to use multiple constraint sets.

I'll try this on the challenging full extension bearing rail with the multiple segments.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Make the two distance constraints. (not offset planes needed)

Select the mechanism button and it will default to General.

Select Translation 1 and pick your movement references.

Set your zero/regen and limits.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Kevin,

It looks like you arrived at a totally different correct answer but a few hours after Miles.

As I remember the General mechanism wasn't happy with with the telescoping segments of the full extension bearing rail but I'll try it on the more basic assemblies.

Vince

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is a multi stage slide extension, I created a couple days ago, that was assembled with General mechanism and works well. Each stage has to be constrained to the previous stage, not the first.

There is always more to learn in Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That looks great. Do the stages stay evenly spaced through the travel?

I was pleasantly surprised to find that was the default behavior when I made this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

They stay roughly even when pulling the last one, but I don't believe that that is a hard constraint. I can move the 2nd stage and the higher stages will maintain their position relative to the 2nd stage.

Diving deeper into mechanism there probably is a way to add that constraint.

There is always more to learn in Creo.