Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- Analysis

- Assembling different materials in Creo Simulate 3....

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Assembling different materials in Creo Simulate 3.0

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Assembling different materials in Creo Simulate 3.0

Hello,

I have a cantilever composed of a rectangular tube made of Alu into which is inserted a Steel U to strengthen it.

There are no games between the two parts.

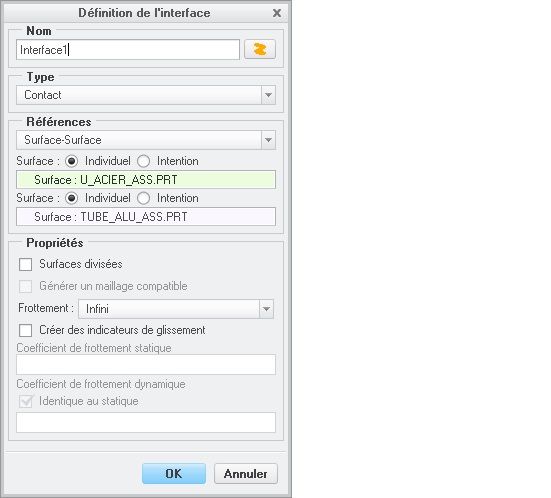

The 5 faces in contact are defined manually with infinite friction.

But in the final result the two parts do not remain in contact, there is displacement through the matter.

What more should be proposed for contact?

Cordially.

Denis

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Denis,

Do you have the press fit control turned on in your analysis?

Silulate sometimes does not like line to line components and sometimes ignores the contacts.

Another option is to cut back the outer surface of the internal part so there's a very small air gap between the 2 parts so the contacts are invoked.

Hope this helps,

Don Anderson

Don Anderson

No time Like the Present!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Danderson-3,

The part between iron, between the two parts is zero,

I do not understand this control:

Do you have control of the pressure adjustment activated in your analysis?

Contact surfaces are defined manually (not automatically)

Cordially.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Denis,

Verify that you have press fit enabled within your analysis to ensure the contacts are are processed for the line to line surfaces.

Don

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Denis,

You may also want to verify that you are displaying the results 1 to 1.

If you scale up the deformation for the display of the results the system may be exaggerating or displaying interface/result.

Don

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Dandorson,

Thank you for this information, I'll take it back in a moment.

I would keep you informed of the results.

Yes, if we increase the scale of the results there are exaggerated deformations.

Cordially.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Danderson,

I had filled the page for the contactes.

See the attached page.

Cordially.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Denis,

I would set the value for the press fit control to 0.5 or something just over zero.

This will make sure all of the outer surfaces of the internal part are pulled inside the outer component and allow the contacts to be fully processed.

Thanks,

Don

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Danderson,

I just redo the simulation with the 0.5 mm and it has not changed anything, it's exactly the same picture.

Cordially.

Denis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Denis,

Verify the displacement result's are being displayed at 1:1 ratio?

Would your load being applied be high enough to shear/displace the alumuinum where the load being applied?

Don

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello,

Thank you for this very complete example.

This is pretty much what I had done, but blocking the two pieces on one side and loading the two pieces on the other.

Now why the springs, two in the front and one in the back, I had never done that.

Why this BLANK material in assembly?

Sorry to ask you these questions but this way of doing things is new to me and very interesting.

Cordially.

Denis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Denis,

The springs have a down side as they may add a singularity and they do add additional calculations to the analysis.

They were added to stabilize the component with no bonded constraints or displacement constraints who's location was controlled by contacts. The blank material was just a place holder that I forgot to remove from the assembly.

Don