Community Tip - New to the community? Learn how to post a question and get help from PTC and industry experts! X

- Community

- Creo+ and Creo Parametric

- Analysis

- AutoGEM and Analysis & Design Study give different...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

AutoGEM and Analysis & Design Study give different mesh results

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

AutoGEM and Analysis & Design Study give different mesh results

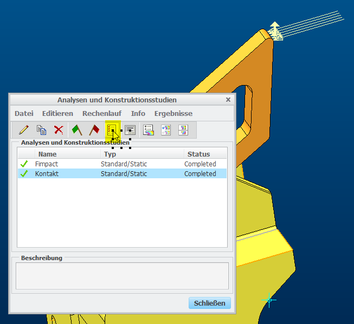

I have a model that I'm trying to run an analysis on but I can not get it to mesh properly. It is a very odd situation because I can mesh it no problem in AutoGEM and view the mesh results with no errors or warnings but when I start the Analysis and it attempts to mesh the model, I get a completely different number of elements in the mesh and errors. I have tried deleting all the existing mesh files, deleted the folders for the Analysis and even copied everything to a new folder and I get the same results....AutoGEM makes 125k elements, Analysis and Design studies makes 105k elements with all of the default options.

Anyone have a clue what could be going on here?

- Labels:

-

Simulate

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

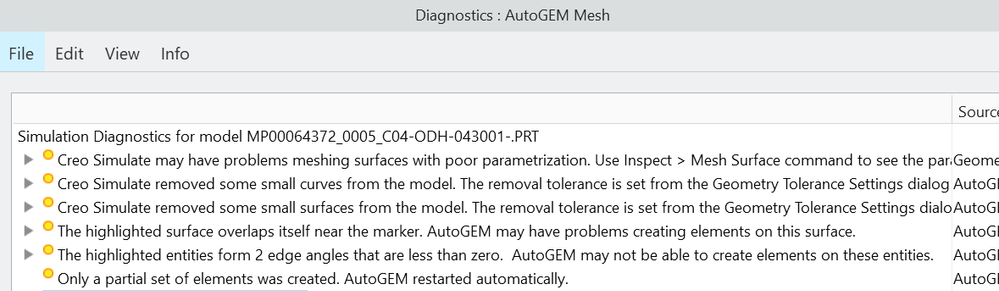

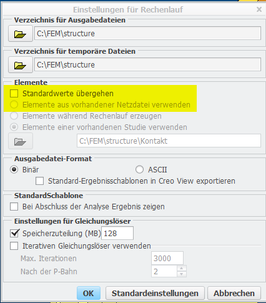

I have tried every combination of the "Elements" options including overriding defaults and disabling it altogether. It makes no difference in the results. However, I have noticed this message whenever I try to run the analysis:

Copying elements from an existing mesh file ...

Element copy failed. Creo Simulate will automatically remesh.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think it is a large model, with screws or rivet elements?

I had something like that very many years ago.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

After playing around with the geometry I have received a new error message when running the Analysis, but I don't know what it means or how to determine where it is located:

AutoGEM created solids that penetrate the boundaries of volumes

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

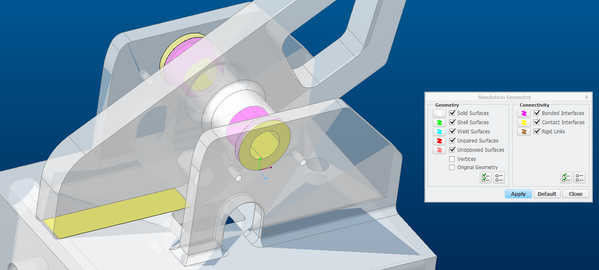

The source of the problem is bad geometry. Likely you imported the or parts of the model from another CAD system, but not necessarily.

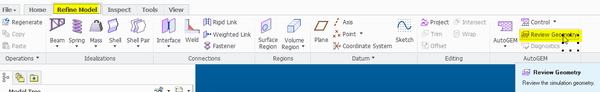

When running with an existing mesh the mesh is compared to the geometry to see if it is a complete mesh. If there are significant approximations of the mesh to fit the geometry then this check will fail and it will try to re-mesh, however due the underlying existing mesh it has a harder time. The mesh diagnostic is the primary way to find where the geometry needs fixing so "A complete mesh already exists..." is successful. Not every error needs to be fixed so it takes some judgement and trial an error to find the root cause geometry problem. Also, if I remember right there are some mesh settings that may not be treated exactly the same pre-meshing vs mesh at analysis run, so sometimes one or the other way is more successful at meshing for that reason. The diagnostics are pretty good at highlighting the geometry with trouble but in a pinch you can do the old method of a binary search by cutting your model in half and seeing which half works and which half doesn't and then continuing to divide in half until you can identify what geometry is the culprit. We use import data doctor a bunch because our models are generally imported and almost always have trouble areas to fix. If you want more specific help and you are allowed to upload the model, someone at the community could take a closer look and show the exact issue and get you on your way again and better for the experience.