Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Bonded contacts on two cylindrical surfaces

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Bonded contacts on two cylindrical surfaces

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Bonded contacts on two cylindrical surfaces

Hello Everyone

I am trying to use bonded contacts on two cylindrical surfaces; however, I get this error "Selected surfaces can not be used for this connection".

I believe this error because I have cylindrical surfaces to connect.

Can anyone help me in how to use bonded connection for cylindrical surfaces?

Thank you in Advance.

- Labels:

-

Creo Ansys Simulation

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You didn't describe your application but can you add points to the line contact on both cylinders and then make rigid links between the points? That will make the connection.

If you are trying to do something in compression you could make them contact surfaces and then Simulate will add springs in the background and make the connection that way.

You could also make small flats on the cylinders and then mate them at the flats.

You will have to judge what is best based on your application.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you Chirs

I am working on a modal analysis, where I need 2 cylindrical surface to be bonded.

Does using rigids and bonded contacts gives the same result?

I can connect them using rigids but not using bonded surface.

Same error as mentioned in this post: Article - CS151670 - Error Selected surfaces cannot be used for this connection appears when creating a bonded interface (ptc.com)

However, it doesn't explain how to use bonded constraints.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Rigid Links (otherwise known as RBE2s) are similar but not the same as a bonded constraint. You need to be careful with RBE2s because they make the references rigid which can add stiffness into your model that may not be there in real life. Ridgeid Links (RBE2s) are so named because they remain rigid without any flexibility. If you are not focused on any data coming out of the surfaces constrained with RBE2s then it could be fine. Doing FEA is a bit of an art and something that comes with lots of practice.

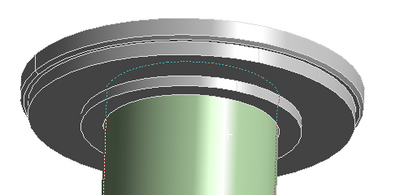

It appears from your picture that you have a shaft in a hole? I was picturing two shafts in tangent contact in my mind when you first posted. If you have a shaft in a hole then all you need to do to make it a bonded surface is to close the air gap (ie make the hole the same diameter as the shaft). You can add material in a local region if needed. Part of doing FEA is modifying the geometry to make it work for the analysis (ie eliminating small surfaces, interferences and gaps).