Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Re: Flat pattern of a part which was created using...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Flat pattern of a part which was created using a Swept Blend

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Flat pattern of a part which was created using a Swept Blend

Hello, everyone!

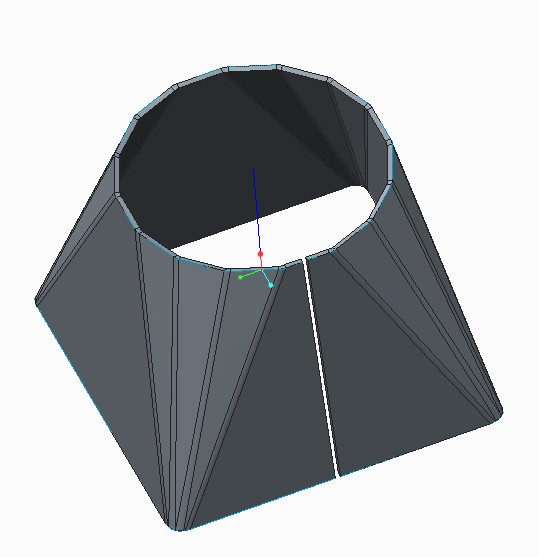

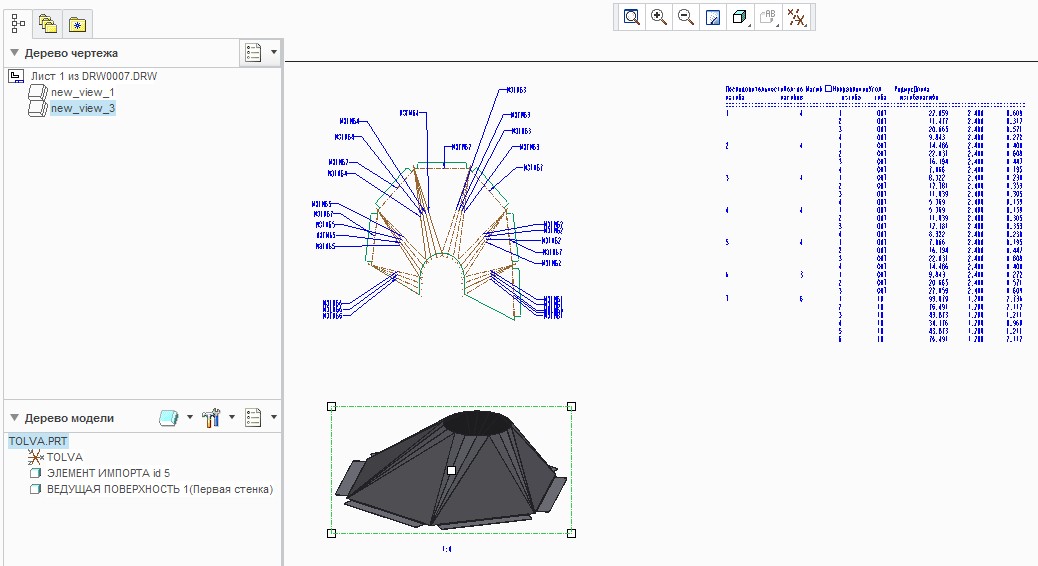

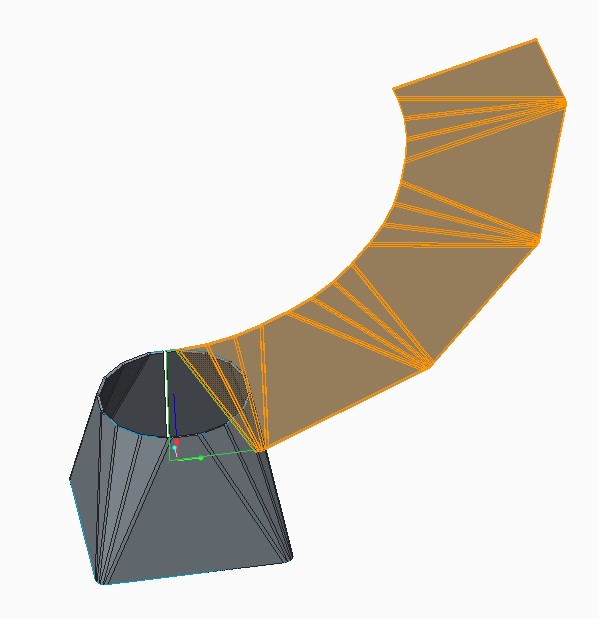

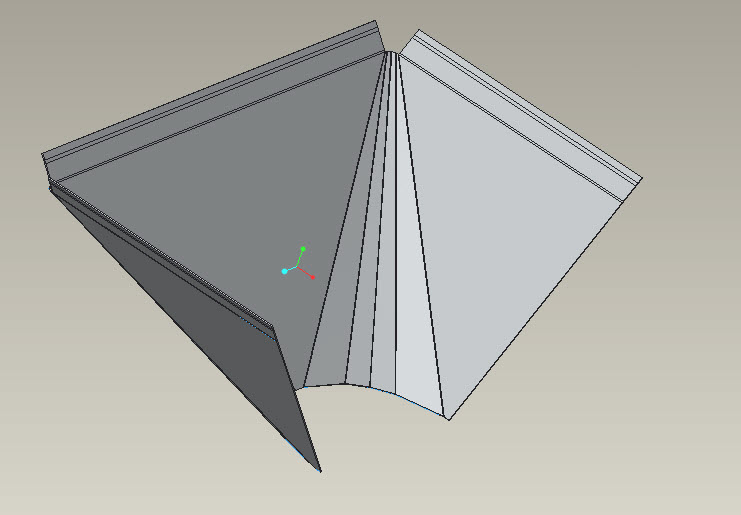

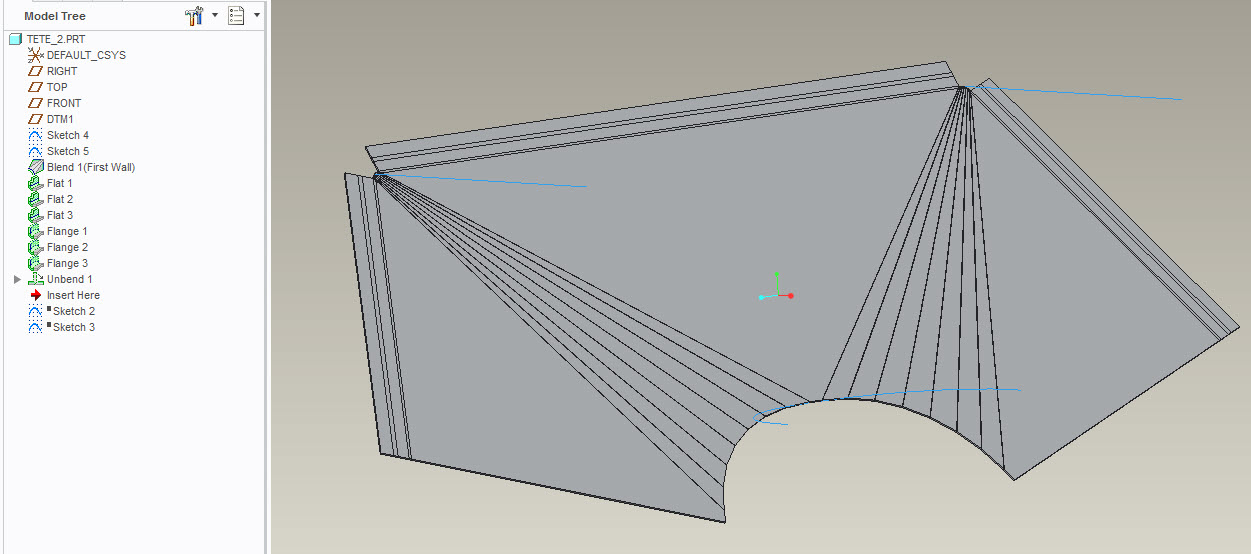

I would like to get a flat pattern of a part, which was created using a Swept Blend in the Sheetmetal Module of Creo Parametric.

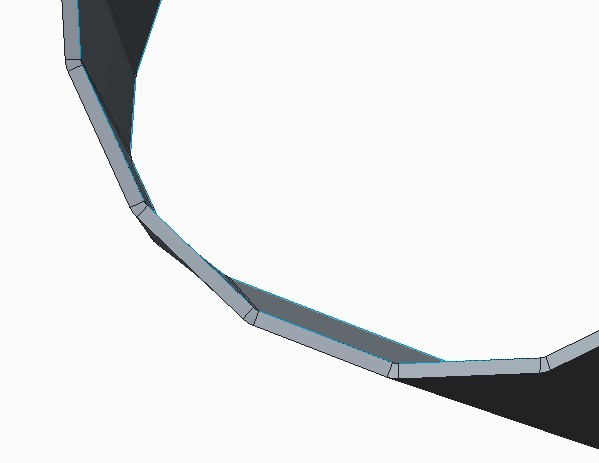

This Swept Blend consist of two sections. Each of them has the same quantity of segments. I used a Convert Tool to add bends on sharp edges to round sharp edges.

But when I was trying to create a flat pattern of this part, Creo displayed a warning message that there is no geometry to unbend.

Does anybody know how to solve this problem?

I attached a picture and a model of this part.

Thank you in advance.

Best regards, Vladimir.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello, Davor, Antonius!

Thank you for your help.

Eventually I managed to get the flat pattern of my model.

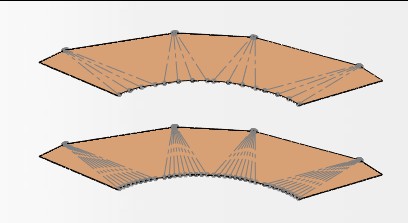

The problem was that some of the sides of my part were twisted. That happend because the lines on the opposite sections, which I used to make the Boundary Blend, weren't parallel to each other.

Best regards, Vladimir.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There may not be enough "flange" along the bottom through the radii to unbend. Maybe try making the triangles parallograms instead.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello, Antonius.

Thank you for you advice. I've tried it but unfortunately it didn't help.

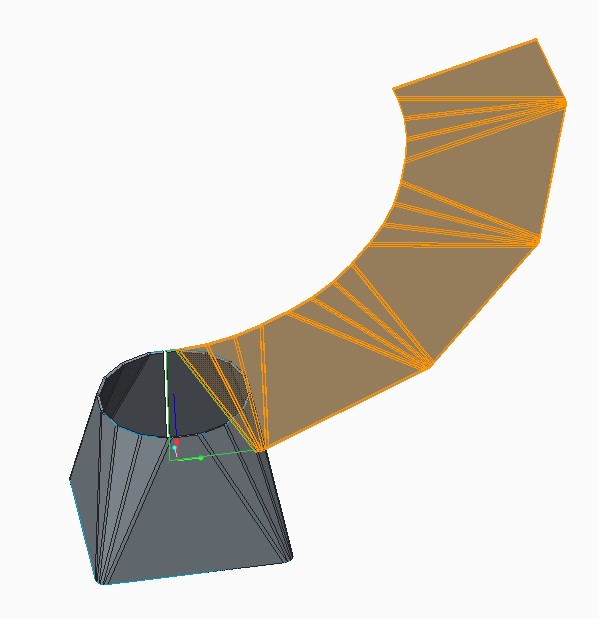

I also attempted to create this part using the Boundary Blend tool. The result was the same. Creo displayed a warning message that there is no geometry for unbending.

That's strange, because I imported much more complicated part which was made in Inventor 2012 and got its flat pattern without any difficulties.

Best regards, Vladimir.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I played with your part a little bit last night. I don't have the full version of sheet metal appearantly because I couldn't blend with thickness or radii. Makes the default sheetmetal kind of useless for me although I do a lot of boxes and panels. I just rarely need to unfold anything so no biggy. I know how to calculate my own bend allowances.

As for why your part won't unfold, I do not know. I was a bit surprised as to how the two sketches meshed with a few extra lines connecting them.

I think I'll stick to the simple stuff for now. So many things I know are there but just can't find it on the new interface. Give me the old 2000i legacy intereface and I can fly ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Vladimir,

You have same problem answered here http://communities.ptc.com/message/165189#165189

You also have part that can be unbent there for download.

Cheers

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello, Davor.

Thank you for your answer.

Actually, I've seen your model before. That's great. I repeated it step by step and flatten it.

That is the reason why I attempted to use the Boundary Blend tool for my part.

But I would like to exchange every conical bend for four angled bends in order to create a Table of Bends (as you can see in the picture above). I would like to show bend lines in a view with a flat pattern and point the value of the angle of each bend in the table of bends.

When I try to use your technique for my part it doesn't work. I can't flatten the model.

Best regards, Vladimir.

P.S.: There is an option in Lofted Bends tool in SolidWorks which is called Bend Line Control. It enables you to set the number of bend lines for conical bend.

That's what I'm looking for in Creo Parametric.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I guess you need to put it in "idea" area as a enhancment request.

Maybe you can make quilt from outer surface and flatten it then use Flatten Quilt Deformation tool on solid part. To me its too much work. PTC must make something simpler.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello, Davor, Antonius!

Thank you for your help.

Eventually I managed to get the flat pattern of my model.

The problem was that some of the sides of my part were twisted. That happend because the lines on the opposite sections, which I used to make the Boundary Blend, weren't parallel to each other.

Best regards, Vladimir.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Vladimir, I am happy that you achieved your goal.

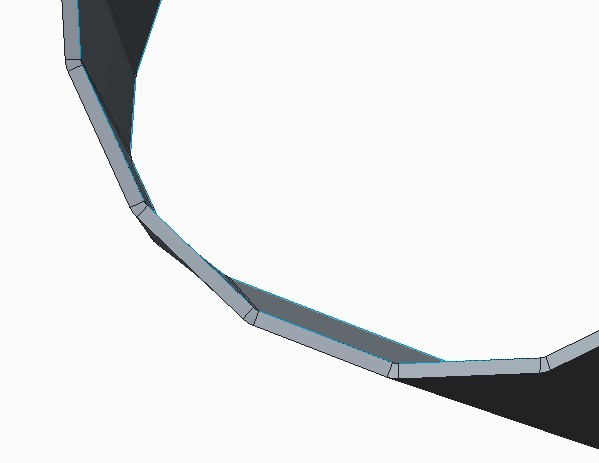

The error you found explains why I saw the extra extension lines... and in hindsight, I remember seeing an odd alignment along the top edge of your part. Now I understand what to look for.

Thank you for reporting your findings.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Vladimir,

I'm with problem in a part similar. How do you resolved?

best regards,

Cesar

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Antonius,

Thank you for your answer. But I was unable to do.

Best regards,

Cesar

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If the faces of those corners are not perfectly flat, it cannot unbend the part.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is another relevant post:

One tool to find the problem faces is the option:

config - mesh_spline_surf yes

If you see lines through a surface in wireframe display mode, the surface is twisted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I did do, but I don't know how. I made a copy an exemple.

Thank you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

See - Easy! ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

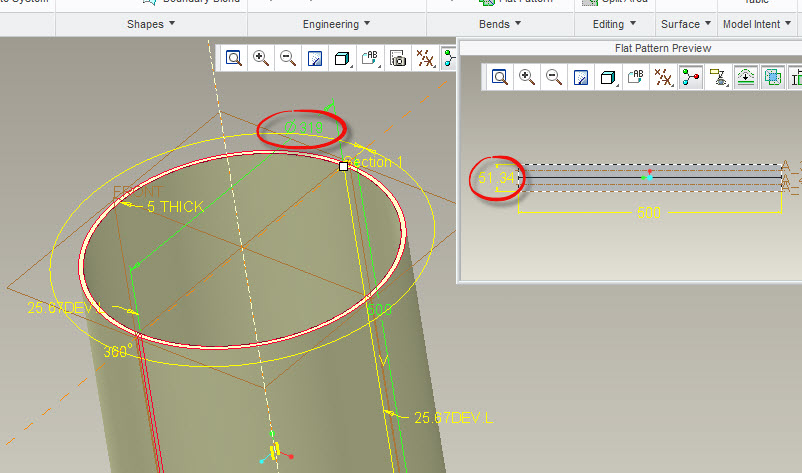

another question, do you know why (figure)?

Best regardes

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It all depends on how this was made. It meets the development length x 2.

If this is a full version Creo file, we can have a look. You can post files using the advanced editor.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you!

César

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

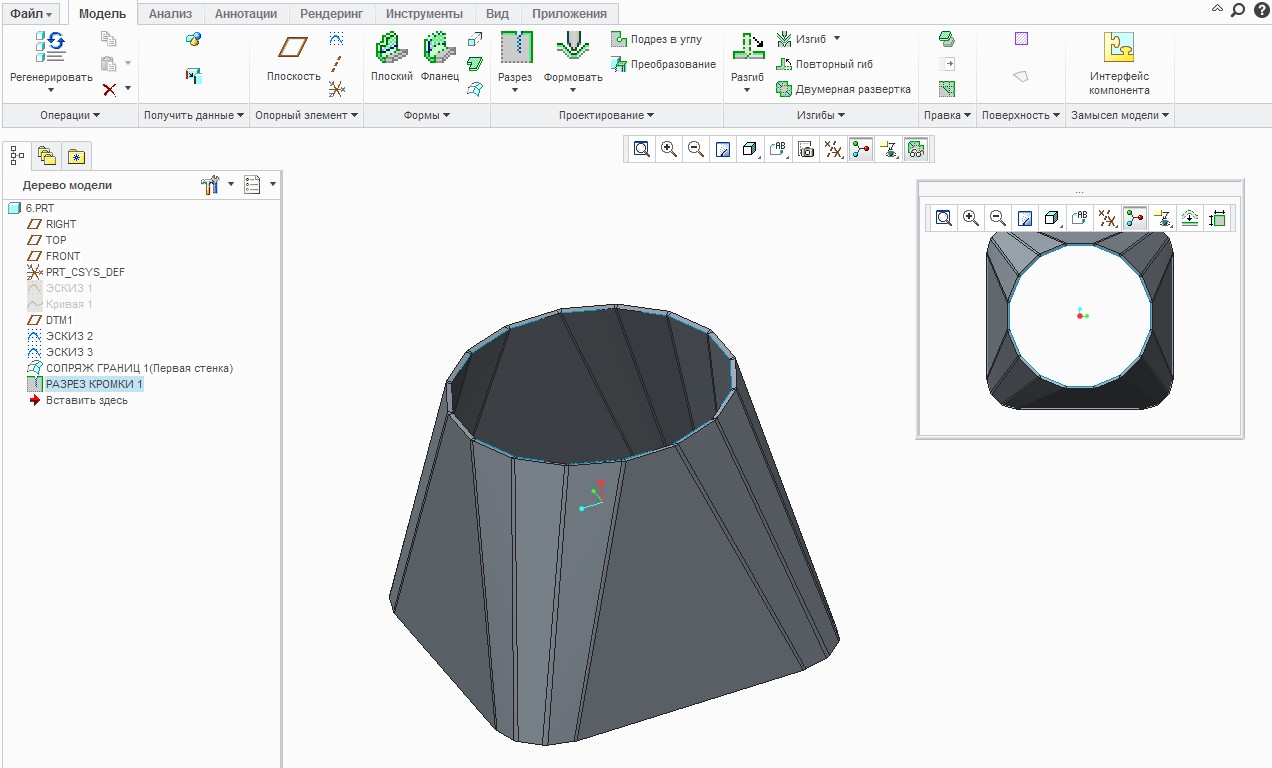

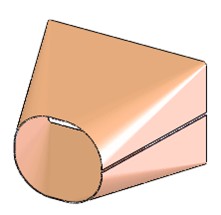

This is what the cylinder part should look like in flat pattern.

I am using the default Y-Factor.

Notice that I used a revolve to get the initial shape.

Then a rip to separate this; and the Split Area to have the unfold happened across from the rip.