Community Tip - Did you know you can set a signature that will be added to all your posts? Set it here! X

- Community

- Creo+ and Creo Parametric

- Analysis

- Re: Poor meshing results - Tesselation in Flow Ana...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Poor meshing results - Tesselation in Flow Analysis

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Poor meshing results - Tesselation in Flow Analysis

I am getting very poor meshing results. Some regions are plenty of spurious holes where no mesh is defined, and I end up with many subfeatures. I believe this issue is a consequence of using a coarse tessellation, but I find no way of changing it.

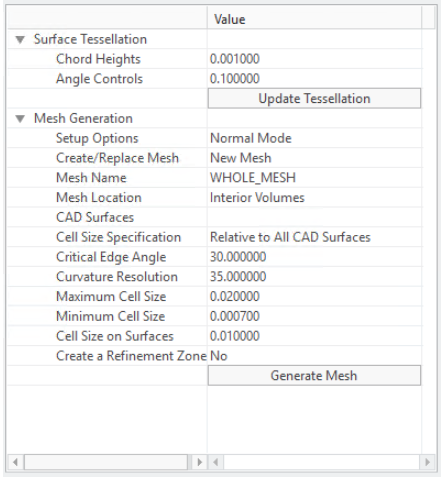

In fact, the help does not mention the difference between "Simulation" and "Regular" tessellation. I have found that regular tessellation does not produce interfaces between contact regions and is, therefore, useless for heat transfer problems. While the regular tessellation allows changes in "chord heights" and "angle controls", the simulation tessellation does not. It gives a rather coarse result that I need to refine.

Please, help.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

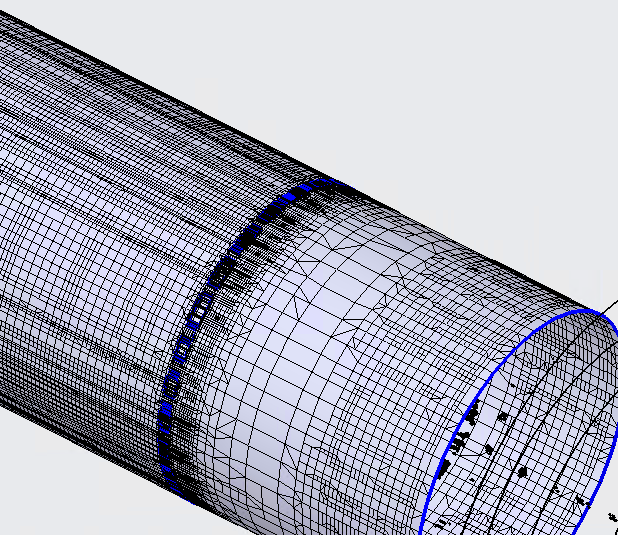

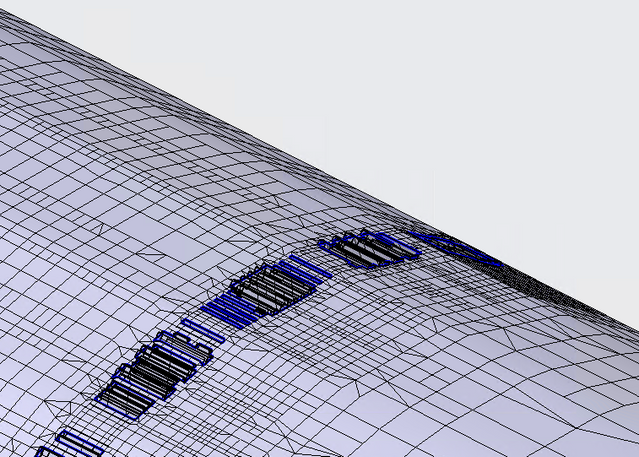

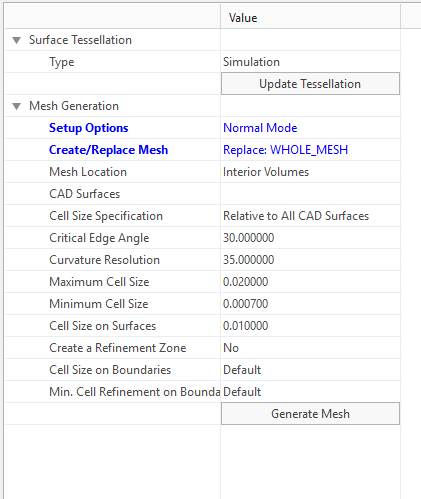

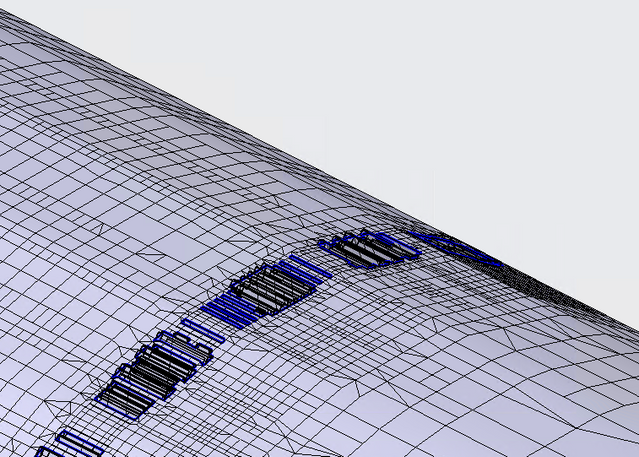

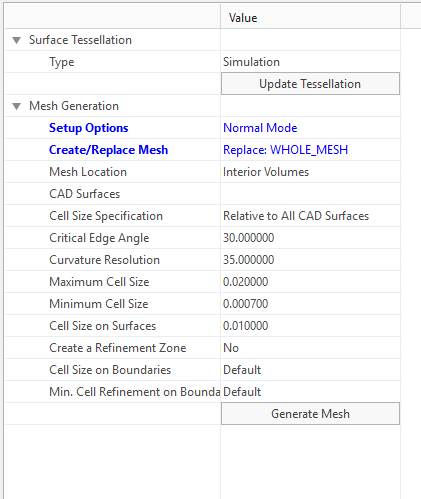

Thanks. Here is a couple of pictures where you can see the spurious holes as well as the result of the coarse tessellation. Although my surface is cylindrical, the tessellation has produced a polyhedrical surface that is apparent especially on the second picture.

The process I am trying to simulate consists of a chamber filled with argon, a heating element that increases the temperature of the gas, a fan that forces the convection of the argon, and a load to be heated. I am using the turbulent flow with heat exchange. I am looking for the temperature of the load for a given power on the heating element, and also for the temperature on the boundaries of the chamber, where I have set a convective condition for heat dissipation.

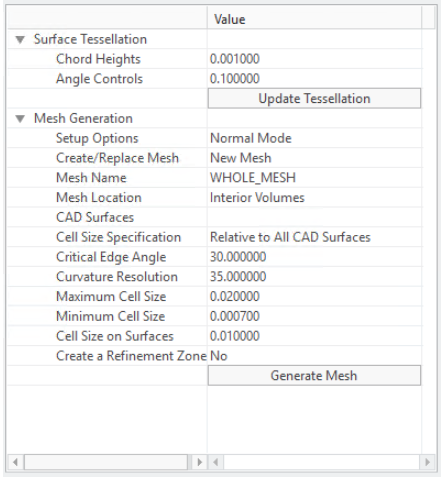

One thing I mentioned above is that tessellation cannot be changed. There is a difference between what the help shows and what actually appears on the menu where the options "Chord Heights" and "Angle

Controls" are not available.

Regards,

AAI

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Could you share with us some pic?

Which kind of analysis/results are you getting for?

Bye

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks. Here is a couple of pictures where you can see the spurious holes as well as the result of the coarse tessellation. Although my surface is cylindrical, the tessellation has produced a polyhedrical surface that is apparent especially on the second picture.

The process I am trying to simulate consists of a chamber filled with argon, a heating element that increases the temperature of the gas, a fan that forces the convection of the argon, and a load to be heated. I am using the turbulent flow with heat exchange. I am looking for the temperature of the load for a given power on the heating element, and also for the temperature on the boundaries of the chamber, where I have set a convective condition for heat dissipation.

One thing I mentioned above is that tessellation cannot be changed. There is a difference between what the help shows and what actually appears on the menu where the options "Chord Heights" and "Angle

Controls" are not available.

Regards,

AAI

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello AAI,

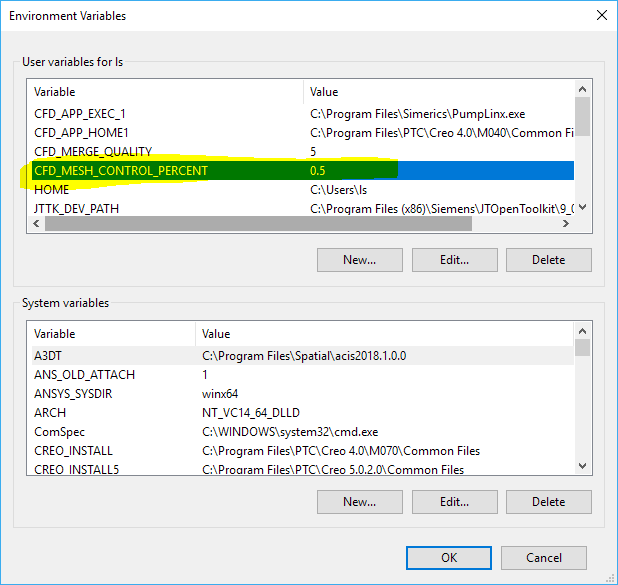

There is a way to change simulation tessellation resolution. You can define a global environment variable

CFD_MESH_CONTROL_PERCENT

By default it is 4, please try 0.5. It is a percentage of overall model size. The smaller the finer. But you need to restart creo parametric to take the changes. We will expose this as a parameter of tessellation in the future version.

For conjugate heat transfer, you can not switch to regular tessellation as you mentioned that there is no interface created between bodies. To reduce the subfeatures, you can also decrease the min cell size. Please email us if you got further questions we really want to help you. Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It worked, although there are still some minor flaws in the mesh.

I am happy to hear that this control parameter will be exposed.

Thanks for your reply.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi AAI,

Glad to hear that. We will add that control as a parameter very soon. Please just message any additional questions regarding creo flow analysis. Thanks.

Lei

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Can you please clarify what you mean by "soon" and "very soon", as ~2.5 years later its still not there in v7.0.4.0

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Could you please pass your request to PTC? It is creo parametric function. It is not control by me. I'm also waiting for it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I will do that as part of my wrap up from a current evaluation.

But why did you write "We will add that control as a parameter very soon", if its not up to you or your company ?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

So what, I'm waiting for the same thing as you at that time. I was told it will be ready very soon. The current way to specify tessellation resolution is working well. what is exactly your problem here?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

My problem is that you posted information that isn't (yet) true, and phrased it in a way that suggested you were in control or at least influencing the implementation. Unfortunately, since you did not edit it or post an update, it is misleading, and it leads people to look for a setting which is not there.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Please use CFD_MESH_CONTROL_PERCENT before we get more controls from creo parametric. Please report your request to ptc. Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks,and I have some questions ,I want to send some videos and creo parametric documents could you show us your e-mail?