Community Tip - When posting, your subject should be specific and summarize your question. Here are some additional tips on asking a great question. X

- Community

- Creo+ and Creo Parametric

- Customization

- Re: How to calculate flat/flange outline length.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to calculate flat/flange outline length.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How to calculate flat/flange outline length.

Hi,

We try to program the way the sheet metal cut dimensions are calculated.

This method does not use the Y-factor.

We have an Excel table for elongation length per bend (Ex. 2.5mm/bend) by material and thickness.

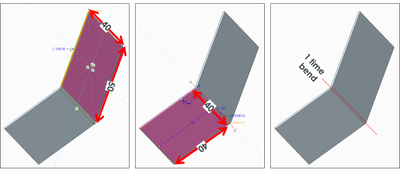

The user calculates the dimensions of the wall, flat, and flange of the sheet metal model as shown.

In this case, it would be 90x40.

Then, after checking the elongation length from the thickness of each material, it is multiplied by the number of bendings.

(2.5 * 1 bends in this case)

Subtracts the result from the corresponding size.

The cut dimensions are then calculated as 87.5x40.

In this process, the number of bends through the axis could be calculated.

However, there is a problem in getting the size of each wall and flat/flange.

After checking the flat/flange through Feature Visit, visit DIMENSION.

In the case of a wall, the width, length, and thickness are obtained.

In the case of flat/flange, it is difficult to check which is the horizontal and vertical dimensions because all dimensions in the sketch are visited.

Can I get the width and height of a flat/flange feature?

Tahnks,

Warm Regards,

SeonHo Cha

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

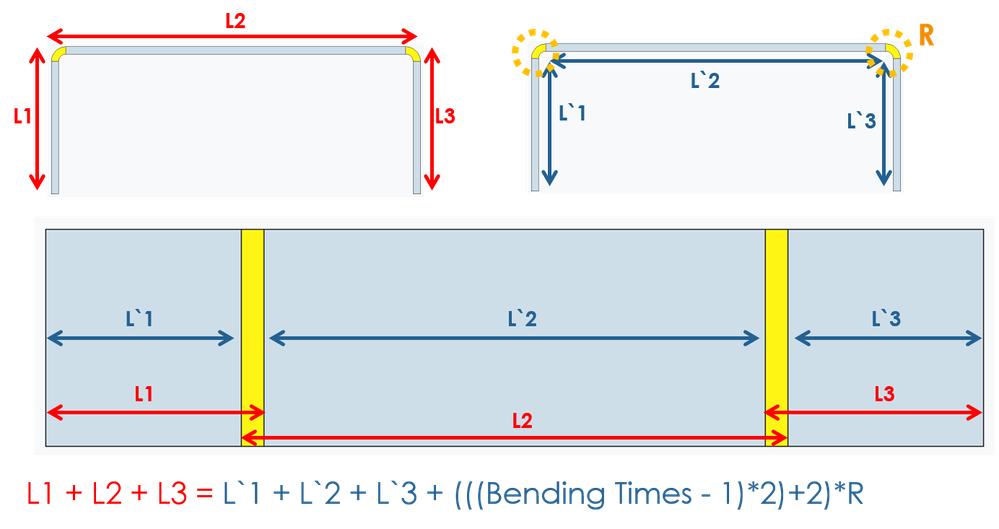

This method works correctly when all banding R values of one sheet metal are the same, and all banding values are 90˚.

1. Check the bending direction

Flat pattern surfaces and axes are created for all sheet metal flat patterns.

The created axis has two directions, A and B.

2. Calculation of min/max values for A and B directions of a flat patterned model

3. Calculate min/max values for opposite axis of flat pattern surface

A flat pattern surface with an axis in the A direction needs min/max values in the B direction.

4. Calculate the distance from the minimum value in the A direction of the model to the minimum value in the B direction of the flat pattern surface in the same direction

5. Calculate the distance from the maximum value of the flat pattern surface in No. 4 to the minimum value of the next flat pattern surface

6. Calculate the maximum distance in the A direction of the model from the last flat pattern surface maximum after 4-5 iterations

Length of all flats including banding:

4~6 distance sum + ((((number of bands -1)*2)+2)*banding R value)

Through the above method, I got the desired result.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

to get a sketch dimension vertical/horizontal sense in model's frame of inertia one could use ProSecdimReferencesGet(...) , trace attachment points to sketch entities and get 2d coordinates of those points, after that to use ProSectionLocationGet() to get a transformation matrix of the sketch and finally to map 2d points to 3d space. This is rather tedious. Another way to solve this problem is to visit edges of the flat surfaces belonging to a feature in question and get edge's length and orientation.

HIH.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This method works correctly when all banding R values of one sheet metal are the same, and all banding values are 90˚.

1. Check the bending direction

Flat pattern surfaces and axes are created for all sheet metal flat patterns.

The created axis has two directions, A and B.

2. Calculation of min/max values for A and B directions of a flat patterned model

3. Calculate min/max values for opposite axis of flat pattern surface

A flat pattern surface with an axis in the A direction needs min/max values in the B direction.

4. Calculate the distance from the minimum value in the A direction of the model to the minimum value in the B direction of the flat pattern surface in the same direction

5. Calculate the distance from the maximum value of the flat pattern surface in No. 4 to the minimum value of the next flat pattern surface

6. Calculate the maximum distance in the A direction of the model from the last flat pattern surface maximum after 4-5 iterations

Length of all flats including banding:

4~6 distance sum + ((((number of bands -1)*2)+2)*banding R value)

Through the above method, I got the desired result.