Community Tip - Learn all about the Community Ranking System, a fun gamification element of the PTC Community. X

- Community

- Creo+ and Creo Parametric

- Manufacturing (CAM)

- Re: Will Pro/NC get better?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Will Pro/NC get better?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Will Pro/NC get better?

Is there any plans for making PRO/NC better like Creo got better from Wildfire -> Creo?

I mean Creo feels much more logical and modern compared to Wildfire. That was a good overhaul wich wich made work much simpler overall.

But I just came back to try Pro/NC again, been using fusion 360 for a while and have not used Pro/NC since WF4 release and that was just hideous.

Some things are better in Creo Pro/NC but for the most part, it just feels like a CAM application from early 2000.

There are not alot of post processors for machines. Seams like there are no post processor that post in heiden dialogue code at all?

Simulations are HORRIBLY slow.

Do I need too keep track of what material i removed by myself? This seams like a BASIC feature of a CAM program.

You still get into the roll down curtain menues from time to time in Pro/NC, they are a nightmare.

Basically, im just woundering if there is any plans in overhauling Pro/NC and making it usefull?

Or will it always be this bad?

Just look at Fusion 360, copy that...

I would love to make CAM work on .prt files instead of exporting .STEP files all the time, but Pro/NC is just so bad atm that I rather export STEP files 😞

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi

Ive been using Pro Nc for the last 15 years or so. I have seen some improvements over the years. I appreciate a couple of the choices of cut types- trajectory had made great gains after creo 2. We have Creo 4 at this point. Cut line, Surface mill, chamfer, round, engrave, face are my go to's. When I am roughing I export my model to 360 cause creo needs to implement a tri-chordal algorithm desperately. Hole making cycles are pretty good.

I do what I got to around stock removal as to help stop air cuts, so I extrude cut my work piece model when I have to. Spent a lot of frustrating hours that caused me to weed out what works and what is more problematic.

I have had hopes that some changes would happen every new release, I do appreciate that it seems more stable and program doesn't crash any more. I think PTC is putting most of their effort in the design, data management areas. Not sure if they will put anything into machining.

It would be nice to hear about it regardless.

I expect some 3d-printer applications will come soon from them.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I agree, NC-module doesn't seam to get much love.

But I would LOVE to be able to make CAM work directly on .PRT files.

So frustrating exporting to .STEP for F360 and then when you spent 30 minutes on that you notices you need to do some changes too the part so back to Creo and new export start all over.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, what do you mean with tri-chordal algorithm? Are you referring to trochoidal milling?

Can't that be done using the scan type "constant load"?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes indeed I do use constant load and it kind of works. Just a few complaints about it. Doesn't have the ability to work the corners as well as some other NC . The higher retracts slows things down too. Anyway I like the look of the mold machining modules. I am wondering if its separate from the complete nc modules meaning a separate license to purchase?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

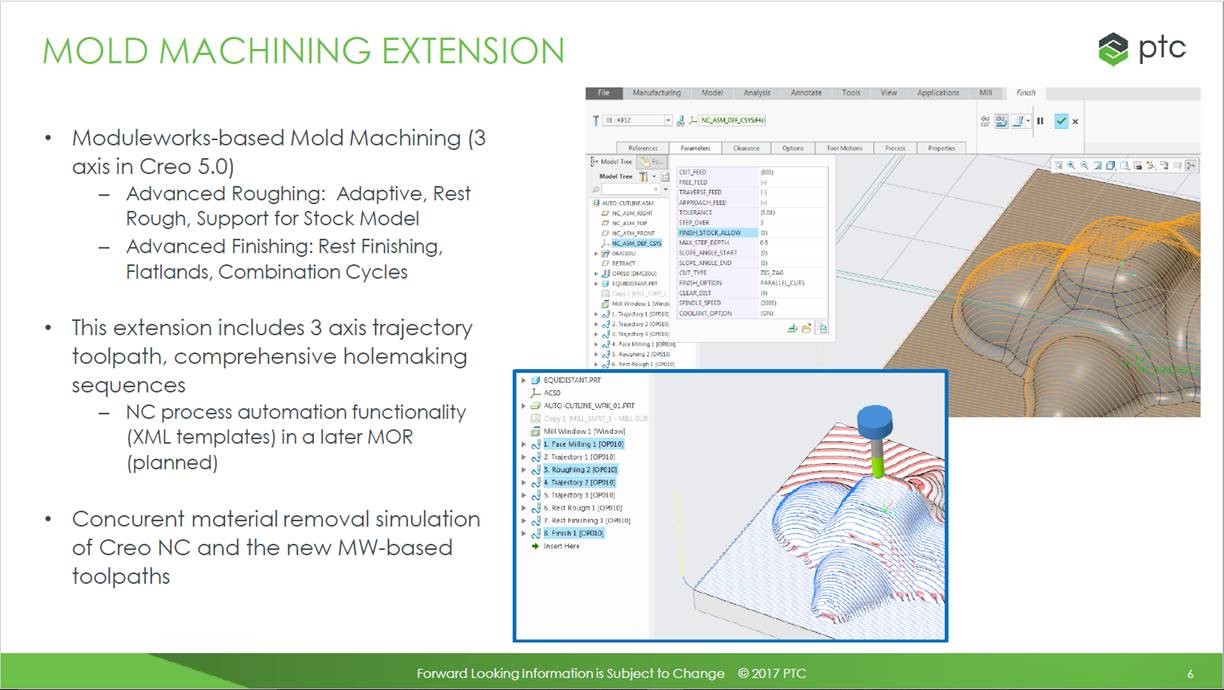

From what I understand, Creo Mold Machining Extension is it's own license so you would have to purchase this in order to use it. It is built by ModuleWorks and there is very little information about what parts of 3-Axis ModuleWorks are included. It is being promoted to the mold industry (hence the name) as an "easier to learn" product with more options for 3D high speed machining than what NC has to offer. XML templates are a future enhancement so I suspect there is no template capability with the product as it stands today. I haven't seen much more than what is in the images below.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I work in a small mold shop and I personally am really sad to see that PTC has decided to "buy" this technology rather than fix or enhance what they already have. I for one will not be purchasing an additional addon package for mold machining just for the latest HSM technology.

We went down this road before with the ProToolmaker package a few years ago. That was a real mess that never worked as advertised. I hope this package work better for whoever can afford and wants to buy and maintain more software

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Agreed Steve, this is a band-aid approach that I wish them luck with. (Don't get me going on Pro/Toolmaker...) Pro/NC was primarily geared toward production machining and I believe it still is, but PTC development seems to be more about life-support on that product vs. real technological enhancements. It is still a decent tool and for things like electrode design and programming in the mold making industry it can work great. But when it comes to highly efficient roughing and hard milling of tool steel, they seem to be stuck in the 90's...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The way I see it those of us in manufacturing are making do with old technology while the programmers at PTC are chasing new technology like additive Man and IOT stuff that means nothing to me as a CNC Programmer.

They throw us a bone every now and then like updating the surfacing interface in Creo 5 that has been around since I started using ProMan Back at rev. 18. I am not sure that is even worth updating to Creo 5 for.