Community Tip - Did you know you can set a signature that will be added to all your posts? Set it here! X

- Community

- PTC Education

- PTC Education Forum

- Re: Cam Toy (Again)

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Cam Toy (Again)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Cam Toy (Again)

Hi,

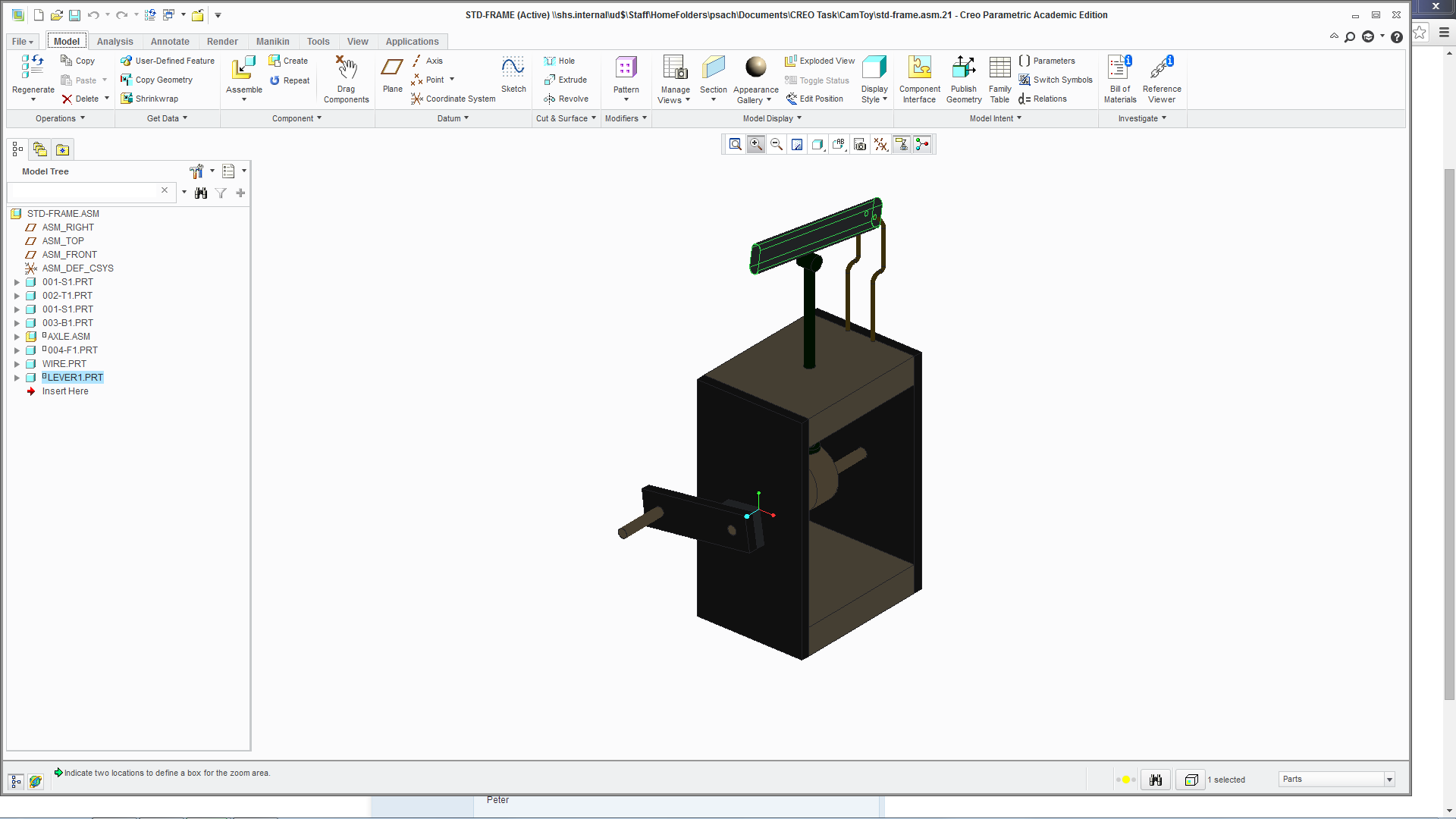

I've got the the basics of a mech going but I know want to have the cam follower push the lever up and gravity let it fall back. I've tried making a slider link but to no avail.

I've attached a zip of the file I'm working on.

Any advice greatfully accepted!

Peter

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It sounds like you laptop is looking for a network license. Teacher's computers should be installed with a single seat license so Creo will work anywhere. I have emailed you privately with a product code and instructions for reconfiguring PTC Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Peter, well done for getting this far! The cam-follower moves perfectly when dragged (kinematic) ![]()

You can use a cam connection between the top of the follower and the beam and enable liftoff if you want the beam to be able to 'bounce' on the follower

You will need to use a dynamic analysis and enable gravity for the beam to drop onto the follower on its own.

I tried the above and the model didn't move and when I looked, materials have not been assigned so the model will weigh several tons! Assign materials to all the parts and you should be all set. With a part open: File > Prepare > Model Properties > Next to Properties click on Change.

Keep us posted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Cheers Tim,

I now have a new laptop so once Creo is installed I should get a chance to have a bit more of an experiment!

Best regards

Peter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Tim,

Had a go at that this morning. nothing playing ball unti I changed the flat contact face of the lever to a radius( by rounfing the edges).

Is this a pre-requisit of a cam connection?

Best regards

Peter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

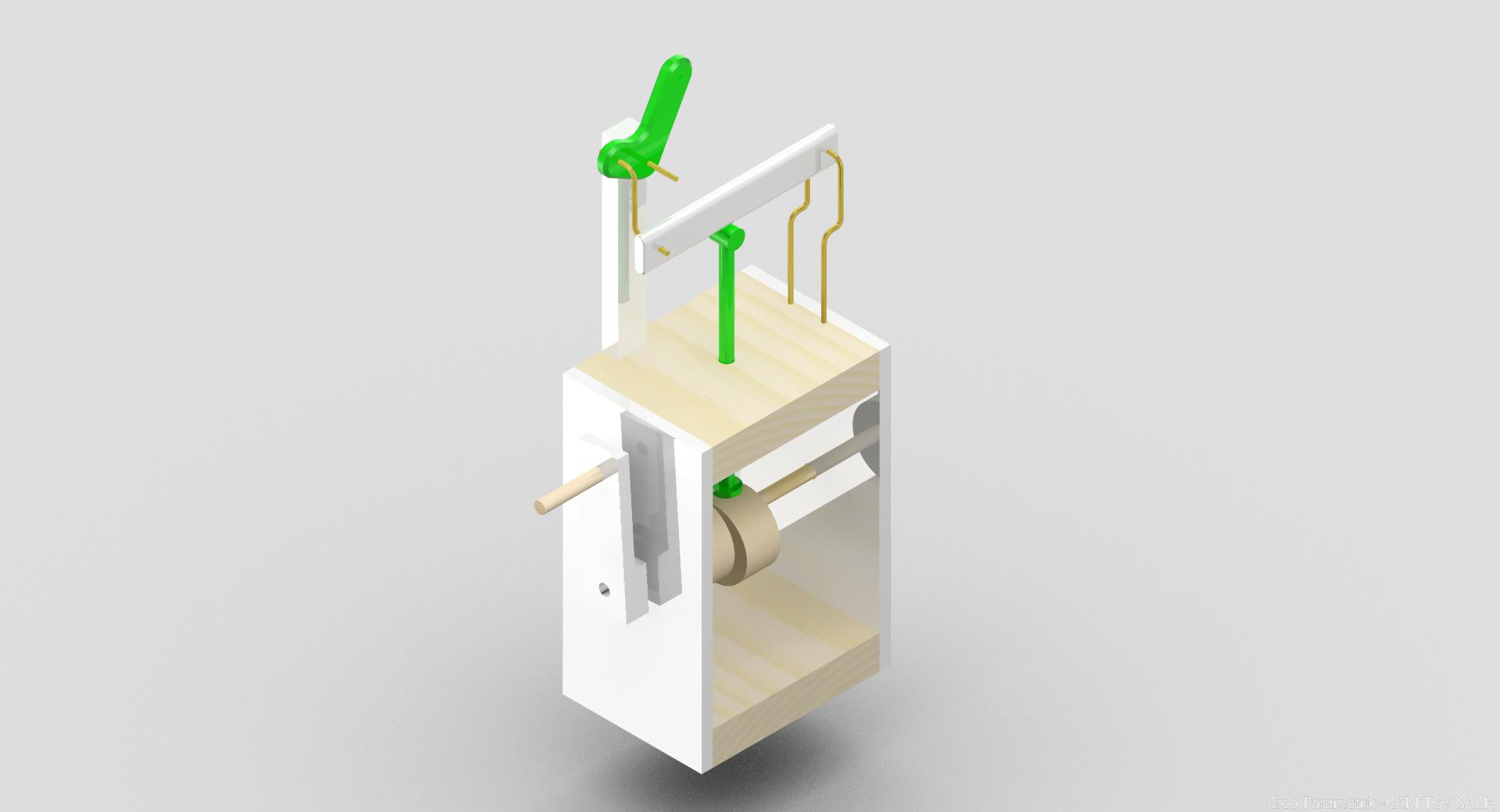

Peter, You can have a flat surface as a cam, the selection method is slightly different. First you select the surface then you select a FRONT and BACK reference to define the width of the flat surface. I usually select adjacent corners.

I applied ABS material to all the parts and checked with Mass Analysis they all had sensible weights. I had to increase the size of the pad at the bottom of the follower, the edge 'dug-in'. I also had to lock dimensions in some of the parts especially the cam. The mechanism now operates with a dynamic analysis with the bar dropping under gravity.

If it would help we could get on a shared screen session and I could take you through what I did.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Tim,

Thanks for that.

I'll get a chance to have a proper look later today.

I managed this yesterday and I'm feeling like your help is helpinh me make the progress I want with the software.

Hoping the new laptop will be ready today so I can leave it doing stuff in the background!

I have an mpg file but i cant use the load video button - the dialogue doesnt show when clicked!

I've attached as a zip.

Best regards

Peter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hey, fantastic work! Rendered too. ![]()

A good spec laptop will make all the difference and, if it has multiple processors, render and analysis will be even quicker. Always happy to help and the offer of a shared screen session remains open.

Keep up the great work!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Tim,

Will ttry to take you up on the offer!

The techs innstalled Cro2 for me. Works great at school. Tried to run at home this evening and got an error msg that bounced me out of tthe programme!

1 step forward!!

Have a good weekend

Best regards

Peter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It sounds like you laptop is looking for a network license. Teacher's computers should be installed with a single seat license so Creo will work anywhere. I have emailed you privately with a product code and instructions for reconfiguring PTC Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Many thanks Tim,

All up an running.

Best regards

Peter