Community Tip - Stay updated on what is happening on the PTC Community by subscribing to PTC Community Announcements. X

- Community

- Creo+ and Creo Parametric

- System Administration, Installation, and Licensing topics

- Re: Processes and tools for 'gutting' products for...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Processes and tools for 'gutting' products for marketing and other external vendors

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Processes and tools for 'gutting' products for marketing and other external vendors

We are trying to automate a process that can gut the internal components of our product and create a step file for marketing and external vendors. Questions:

- What does your company use?

- Can this be done via Windchill and the cadworker?

- What are some lessons-learned and tips/tricks you have found?

- If you are using some third party tool, what is it?

Thanks!

- Labels:

-

System Administration

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have tried shrinkwrap(model>shrinkwrap). I make a new ASM add my complete product ASM then create a shrinkwrap from the product inside the new ASM. I was hoping that with the product as a reference anytime the model updated the shrinkwrap would update and then after a checkin to windchill the windchill publisher would make a step file for me.

That shrinkwrap always needed touch up of surfaces to include and exclude. It would update though. Depending on how complex your parts are this can be a no go because too many little things need to be fixed every update and its easy to miss stuff. I probably just don't know what I'm doing but I never liked the result of the shrinkwrap. The shrinkwrap from model>shrinkwrap is a surface model, I probably could develop further to make a solid but I'm already past my fixing limit for how mediocre the result is.

Solid model shrinkwrap from a save-as operation. I need some holes filled others not. I have a lot of product with conical high pressure connections to customer lines. The fill holes option goes too far. So I need to go about doing it without fill holes and then get to fixing it. This model has no association and no autoupdate with model changes.

No matter what I do I have to fiddle with it. A lot. So I make a new ASM put my product in ASM then make a quick and dirty part in the ASM that fills all the space inside the product. Extrudes and revolves galore as fast as I can putting the ends of the new parts geometry just were I want the holes of the product geometry cut off. Then I merge everything into that new part. Now I have a filled solid inside, the exact exterior, and holes geometry shown to the depth I specified. Windchill will publish a step file. The model will update with the product changes, sometimes fail and need some touch up. The advantage to the touch up(IMO) is its normal sketching of the base geometry for your merge part. Or, its delete all merge features and then merge all again. Still manual, still a pain I know. This gives the exact result I need and I can edit and update edit this type faster as its "normal" modeling in my workflow.

If anybody has the magic of how to make customer models automated that show just what you want. Nothing more, nothing less. I'm interested.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting approach. I agree, we are also spending too much time with this. Thanks for writing up a great response!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

My process is "specific" to sending to customers who want/need our product in their overall layout. Usually they are looking for the major interface areas.

It takes out as much internal information as I can reasonably remove.

Below is a copy of how I documented it so others within our group could follow the same recipe:

See below for the steps I used. The kicker on my process is I end up cutting away some surfaces and then re-adding back in some models that I consider “major interface components”.

It’s the fastest process I have come up with. Is the least prone to failure with respect to save as and export within creo. Also, it gives away the least amount of information that I have seen.

********

The purpose of this is to provide a customer with a “reasonable” 3D model without giving them (or whoever they may send the file to) too much information on internal components.

This procedure will produce a single part file surface model that includes dimensionally accurate interface geometry but will only be a “shell” file with almost no internal geometry.

- Open the LMRP or Lower stack, preferably in the stack layout rep. It may be wise to remove major interface components, examples include connectors, mandrels etc.

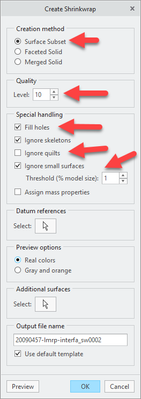

- Create a shrinkwrap of the assembly using the following options (file – save as – shrinkwrap)

- Surface Subset

- Level 10

- Fill holes

- Do not ignore quilts

- Ignore small surfaces - 1%

Always open the shrinkwrap and verify what you are left with. It should be mostly just an outer “shell” of surfaces with few or no internal details.

- Once the shrinkwrap is created, you will notice the fill holes option has “covered” some of the interfaces. You will need to cut away those surface to be able to re-add the major interface components.

- Make a new assembly, add the shrinkwrap at the default coordinate system. Assemble the major interface components back. It may be necessary to go back to the master creo assembly to get appropriate dimensions for re-assembling.

- Create a new shrinkwrap of this new assembly using the following options

- Surface subset

- No fill holes

- No ignore quilts

- No ignore small surfaces

- Save as a step file. Make sure you the step options include quilts and in the advance settings, the “export solids and quilts as” SURFACES.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Stephen,

Thanks for your feedback. A little similar to what we are currently doing.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's not a clean process and takes a lot of user decisions and adjustments but it solves our specific problem. We send files to other large manufacturers and there is a risk they will take our models and make their own products. Well, at least that is the concern.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

attempt at humor: Can't argue with a 1 step process.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hahaha, I hadn't noticed that!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

OMG, that's brilliant!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I might as well discuss our current method. We use a mapkey which does:

- Orients the product to the top and asks the user to select the top part

- It hides the top part temporarily

- It Starts creating a custom rep and redefines it in PROPERTIES mode

- Asks the user to use the cursor and drag a box from the top-left to bottom right INSIDE the chassis for selection

- The mapkey adds those objects completely inside the selection using the simplified rep

- It adds back the top chassis and asks the user to add back any components from the initial selection that should not be hidden (maybe chassis screws, etc.)

- It then completed the simplified rep

- It starts a shrinkwrap file creation with options preconfigured (merged solid, etc..)

- It automatically adds curves for our artwork

- It tries to create the shrinkwrap

- It pauses and asks the user to make sure there was a successful message. Many times it fails and we need to figure this out.

- If it passes, the mapkey continues and opens the shrinkwrap prt and creates a step file from there.

When marketing, or sales engineering is emailing you a few times a week with a handful of products each time, this can definitely add up; especially when the merged solid doesn't work.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We export to step, reimport using

intf3d_in_as_part YESand then cut out what we don't need.

Note that config is hidden because it can cause Creo to crash.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Chris,

Interesting. Thanks for your approach.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is another idea. Let me know what you think.

What is the process requires the engineer to create a 'gutted' simplified rep of the product before release. The Windchill generates an iges file of that simplified rep (where it exists). The iges format automatically can create a 'flat' state which mimics the process of merging everything together into 1 part. Does anyone know if Windchill can use certain simplified reps for some of its representations?