Community Tip - If community subscription notifications are filling up your inbox you can set up a daily digest and get all your notifications in a single email. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Chain solution

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Chain solution

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Chain solution

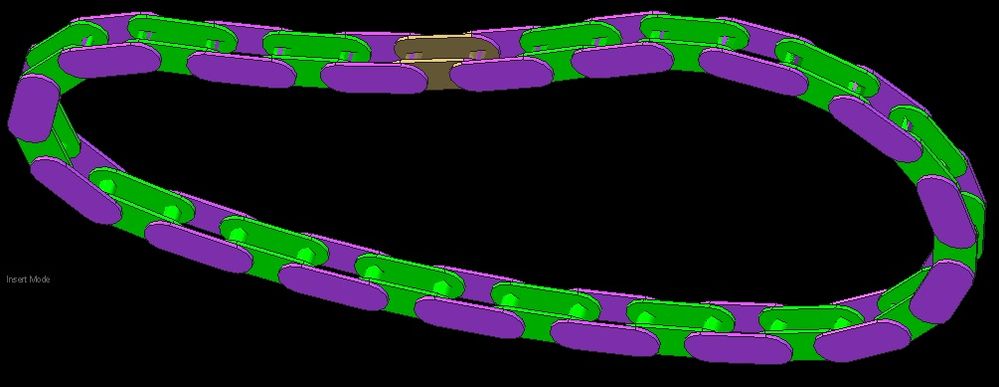

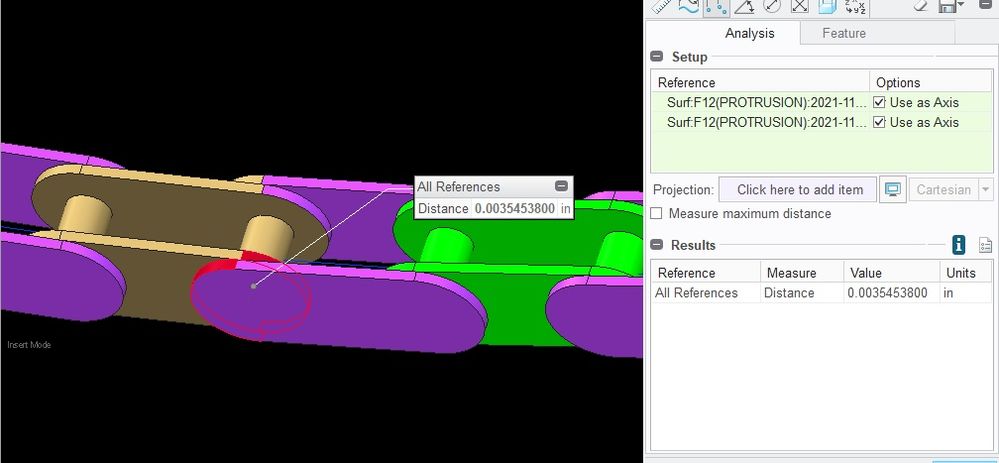

@PM_9971370 Ok, not as perfect as I'd like, but the misalignment on the last pin of the last link is only .0035" MAX (.0002" MIN), so, I'll take it since I'm just doing this for fun. Should be good enough for now. First off:

Caveats:

1. I made links an easy 1" long, not following any actual standard for ANY dimensions (so sue me).

2. I didn't bother to write a bunch of relations as to overall length by # of links, which won't work anyway - see below). Feel free to do....whatever.

3. I picked sprocket size by 2 different arbitrary # of teeth and used the 1" link length x teeth to determine pitch diameter, and used 34 links x 1" to determine the INITIAL perimeter length (which had to be slightly increased - see below).

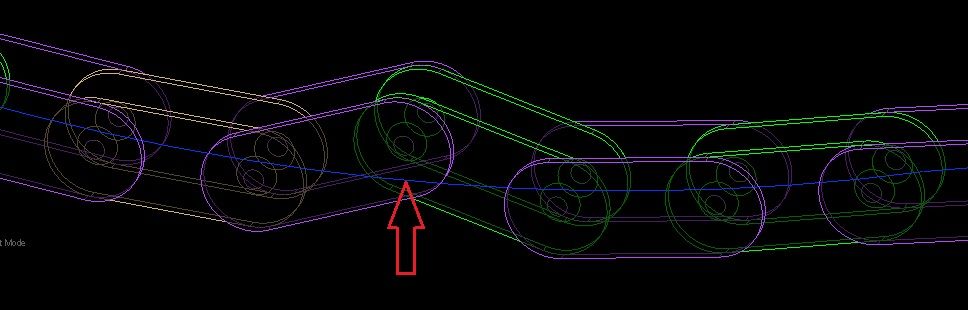

Ok, so, I was going to try and use a bunch of 1" lines moving along a spline to ACCURATELY determone the shape and length of the perimeter needed (the BIG problem is that it CHANGES depending on how many teeth are engaged per sprocket). And, well, splines S@CK, what PTC SHOULD have done was make it a POLYLINE which would allow you to constrain (point on entity etc.) these 1" link lines and be able to drag them around. Nope. So, back to simply using a perimeter dimension of 34" for the curve. Then I the first link (gold) with a "planar" and 2 "slot" constraints. Then I constrained all the next links to use a "planar constraint, a "cylinder" constraint to the previous link, and a "slot" link on the last constraint (far end). While you can't "pattern" these links, you CAN use the "Repeat" command for all the other links, and you just have to pick one axis for the cylindrical (middle "Add") constraint in the pop-up, so it actually goes really fast. So, now you can drag the entire chain around (Wheeee!), and every link drags all the others and follows the curve path....except that you notice that the chain is about .1" too long? What the...? Well, as you pull the links around, you ALWAYS have axis-to-axis (i.e. link) distances of 1", but since the sprockets are a continuous curve with an arc length GREATER than the combined engaged facets of the polygon a chain sprocket REALLY is, the chain ends up being too long. How much varies with the # of teeth on the sprockets. Someone a lot better at math could probably calculate all this to get a "correct length"...aannnd it would STILL be wrong because as I said it VARIES, but I took some measurements, got it to .0002" to .0035" worth of misalignment, and called it done. At first I let the last cylinder connection float, and got what was shown in the arrow. But that led my to changing the last 2 links constraints, and allowed me to understand mow much I need to lengthen the "slot" curve. I used a Skeleton model because I thought the spline feature would work, but that curve could simply be created at the assembly level without the need for a skeleton part at all. For visuals, I made the FIRST link gold, and for the axiis that have that slight mis-alignment at the last link, I changed the surface colors of those ends of the first and last links so you could measure things easily for yourself. It IS pretty neat dragging it along the trajectory, and take measurements of the distance between those misaligned axxis as you drag them to different parts of the trajectory. Anyways, if was kinda fun, not too crazy difficult in the end, took less than a day total, including the limitations in the software mentioned, but I'm satisfied it works for 99% of people, so I'm done. I even put some "Catenary" drooping for fun for my friends @KenFarley ! LOL 🙂

Enjoy!

- Labels:

-

2D Drawing

-

3D Animation

-

Assembly Design

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

33 views and nobody has anything to say? No intelligent discussion at all? *facepalm*

This, in a nutshell, is why I don't bother to post solutions.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for your reply. We know this solution already but the only think is to we have to use the repeat command. But what we are asking is PTC can create a pattern option and every one in the world can use that without trying multiple methods.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, it's a nice dream, so I'm not going to spoil it for you...LOL.

To me, this is the solution. Something automated would be nice, but I'll take being more correct vs Solidworks automation any day.

You guys make blow-molding and soda filling machines?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, I looked at it. Read it. Realized I have never had to make a chain for any of the products I work on. Therefore have never tried to model or even work with an existing legacy chain PRT/ASM. So I do not know what issue this solution is solving. What does Creo do or not do regarding chain design? I can only imagine that its got something to do with the ASM into the chains interfacing parts and the nightmare of getting every link in the correct place....and then get asked to make the chain move around when the gear rotates. I assume this solution is to make the latter easier/possible but I do not know the problem because I never modeled a chain.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

DunamisMachines wanted a solution where all the link pins lined up for all the links in a path. What they weren't clear on is that they supposedly had a solution, but wanted something "automatic" where they could simply pick a path, and simply pattern all the links and it would magically make the path length correct and space the links correctly and equally. I don't know that you'll ever get all that. What I did was make sure all the link interfaces were perfectly aligned except for the very last interface that CAN'T be perfectly aligned centerline to centerline without that interface NOT following the path. You have to pick one or the other, and I chose the way I did it. The worst misalignment I found was about .0035". Close enough for me. As you drag it around, it varies, so, you really CAN'T make it perfect, that's the major problem. It was a mite tedius having to constrain each link individually (though the "Repeat" command REALLY helped), but you simply can't get it to work right using a pattern....not that I found.

I don't use chains either, I just thought it was a good mental exercise and good practice for me since I hardly ever use Mechanism. Were you able to drag the chain around ok?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We are able to drag the chain.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Did you have any issues with the chain suddenly reversing it's assembly direction while dragging? I tried something similar a while back with only some of the links added, and depending on where I stopped dragging, the entire thing would flip around and end up assembled the opposite direction. Guessing it had something to do with how Creo handles angles over 180 degrees.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

'Morning Tom! I know what you mean, that has been an issue for Creo and I have seen it before, but so far I can drag it both ways and not have issues (surprisingly - LOL). I didn't get the perfection I wanted, but I consider that a software limitation because I couldn't set the skeleton up the way I wanted to, which WOULD have given the correct result. This is close enough. I'll never need this, but it was simply an exercise and learning experience. I don't play with mechanism much, I find it kinda tedious and the constraints can be a PITA.

I'm disappointed that the regular constraints for assembly STILL have problems with tangencies. Instead of giving you choices and you flip them to get the one you want, most times you're stuck adding a tangent datum plane and then using a coincident constraint to that. Total BS.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hey Tom! Did you try the files I posted? Did anything flip for you in the assembly?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Just gave it a whirl. No flipping at all. It's heavy, but it functions! Pretty cool. 🙂

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

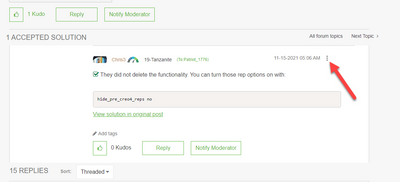

Ah, good deal, thanks for giving it a try Tom! I can never tell if it just works on my system or it'll work on someone else's, which is the true test. I was HOPING to make it a graphics or geometry rep (forget which is lighter) and was astounded that PTC, in their infinite wisdom (Hint: That's sarcasm for people new here... LOL) decided to delete that functionality from simplified reps. When I lease a copy of Creo I'm going back to Creo 3. I'm thinking that would speed things up.

Actually, I had a thought on MAYBE how to make it work as a pattern today out of the blue... Hmmmm.....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

They did not delete the functionality. You can turn those rep options on with:

hide_pre_creo4_reps no- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ah, cool, thanks! Man, I HATE when they do stuff like this. Like I said, when it comes time to lease a copy, it'll be Creo 3. For the few actual enhancements from Creo 3, there's far more drawbacks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That worked, thanks! To me, if they're going to do this and make it invisible to the user who doesn't see the functionality anymore, it's like they deleted it. I've had to turn back on a bunch of stuff (older advanced features like N-Sided mesh, etc.) that PTC in their infinite wisdom decided that I didn't need.

While I was searching for other things they turned off, I found a way to change the sketcher constraints back to the older constraints that weren't HUGE icons clogging up your sketch. MUCH prefer the old style, and had to turn that back on too... *facepalm* Here's the setting for that:

sketcher_pre_creo4_constraints yes

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@MODS: No offense to Chris3, but actually, I very much take issue that this is considered the "solution". It was a solution to a question I asked, but not the solution to the ORIGINAL POSTED PROBLEM. I know that lately you want to mark everything as "solved" to make it look like there are no outstanding problems. But, it is NOT solved, and if you're going to mark something as solved, mark the actual closest solution to the stated problem.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@Patriot_1776 As the original poster, you should be able to hit the 3 dots on the "accepted solution" and select "NOT THE SOLUTION"

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ah, thanks Stephen! I didn't know you could do that. If they want to close it out as "solved" I tried to pick my original post, but it wouldn't let me. Ah well.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Nice. Dragging these links around starts to bog down my system, but I'm impressed it works quite well. I played with it one step further and converted your skeleton sketch into a single spline - but it's funny how you still have to make a multi-selection to form the loop as the software seems to internally convert this loop into two splines (even though 1 is generated by the sketch conversion tool). Maybe it's some general limitation of the code related to the mechanism and slot connections.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yeah, that's what I mean (hence my OTHER thread about this BUG), I did the same thing, thinking the spline would work easier (plus I had an ulterior motive), but it, for some reason, cut it in half, at what looks like an arbitrary location. Whaaaaat? Maybe it's related to the fact that since the very beginning (at least V15 where I started back in '86) Pro/E cuts cylinders (and circles) in half like that, causing TONS of geometry failures over the years. My PC is really old and slow, and it bogged mine a little too, but it does work and didn't flip any links, and is about as accurate as I think you can get because of the software limitations. I tried to make the links a "Geometry Rep" or "Graphics Rep" to speed it up, but in Creo 4 they got rid of that functionality!!! *facepalm* WTH were they thinking? The "Automatic" rep didn't seem to do anything. What a joke, that was one of the great features of Simplified Reps. When I lease a copy, I'm going back to Creo 3.

Glad at least SOMEONE is playing with this, and is willing to discuss it. Good on ya Mate! LOL I don't think this is something I'll ever need, but it was an interesting mental exercise, especially since I haven't used mechanism at all in years.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

FYI, have a look at this thread:

- in the 2nd to last video, PTC expert shows how to turn the chain "track" into a single approximate curve using the copy command, then use this copy as a single reference for the slot connection.