Community Tip - Stay updated on what is happening on the PTC Community by subscribing to PTC Community Announcements. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Constraining Angular Motion of Ball Joint

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Constraining Angular Motion of Ball Joint

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Constraining Angular Motion of Ball Joint

Hello,

I'm creating a motion skeleton to model a motion platform similar to this:

https://www.youtube.com/watch?v=3tSbAjnCR18

As you can see, there are ball joint end rods that connect the motor arms to the platform. I was able to model them using ball joints, but by doing so, I am unable to limit the rod from deviating off the same plane of motion as the motor arms (does that make sense??).

I found a similar topic: https://community.ptc.com/t5/3D-Part-Assembly-Design/Constrain-Angular-Travel-of-Ball-Joint/td-p/185979. No one was able to give a solution but someone mentioned how I could use two perpendicular pins to control the range of motion between two perpendicular planes. I've been trying for a while to get it to work but I keep failing. Does anyone know how to accomplish this?

Thank you!

Solved! Go to Solution.

- Labels:

-

Assembly Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Glad it worked out. It sounds like you had a good learning experience; for me, it affirmed that avoiding motion skeletons is the way to go.

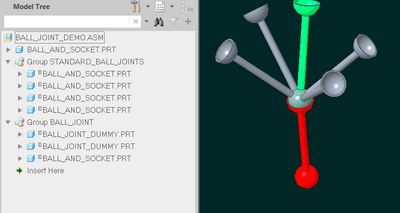

If you are interested, I attached a toy model with the simple ball joints (gray) and the more complicated 3-pin-joint construction which allows angular limits in 2 directions (green):

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ball joint connections allow you to specify a "cone angle" type of motion limit. Does that not work for you?

Can you post a sketch explaining the constraints you require?

- Tags:

- you

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I attached a basic screenshot of the skeleton model. Please compare it to the youtube video in the original post if you can. Essentially there are 4 rod end ball joints (like these) that connect the motor arms to the platform. They give the platform some rotational wiggle room when the platform swivels, but don't allow for extreme angles due to how their connection with the motor arms are.

The first screenshot is a standard orientation for the table. The second is an example of the extreme rotation that occurs because the skeleton model's ball joints cannot be constrained, which is obviously not desired. You can see in the video that the supports move in the same plane as the motor arms, but only have so much room to move to the left and right of that plane.

Essentially I'm asking how the best way to simulate the ball joint rod ends in a motion skeleton. Does that make sense?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sorry I didn't see your first question. I tried using the cone axis but it only lets me use an assembly reference for a link that is connected to the link with a ball joint rather than an assembly plane, like a pin's rotation constraint can be done (i.e. in the bottom left ball joint in the first screenshot, the component reference is the longest arm, and the assembly reference is the short arm connected to that joint).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Sorry, I can't help much because I can't open your files (> Creo 4?)

Also, any reason for using motion skeletons? I consider them to be obsolete technology kept for legacy users.

I wouldn't use them, and so maybe there are limitations there that don't exist if constructing mechanisms in assembly context?

The cone angle seems to work well to simulate the physical limits of the ball end shaft hitting the edges of the mating socket. I imagine some ball joint designs allow/restrict more motion in one direction - in that case, you would need something more like elliptical cone, which does not exist in Creo. So, you end up constructing a kinematic ball joint out of 3 mutually perpendicular pin joints and place the angular limits on each axis' motion...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ah sorry about the files, I'm using 6.0.

I'm actually a college student and very new to creo. Recently the class I am in introduced skeleton models for kinematic studies so I thought I would use them for this project. I mainly wanted to use it to play with the lengths of each feature to get an idea for how all the components move in relation to each other, not necessarily modeling parts directly through the skeleton.

I like the idea of using perpendicular pins, however, when you assign a sketch link as a pin joint, you can no longer assign that link for any other joint, thus why I'm stuck using a ball joint. If you have a solution for that then that would be cool!

Anyways, I resorted to giving up on the skeleton and downloading a rod end from grabcad. Eventually, after placing enough datum features, I properly set the cone angle relatively easily.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Glad it worked out. It sounds like you had a good learning experience; for me, it affirmed that avoiding motion skeletons is the way to go.

If you are interested, I attached a toy model with the simple ball joints (gray) and the more complicated 3-pin-joint construction which allows angular limits in 2 directions (green):