Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Creating a round dimple on a round surface

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Creating a round dimple on a round surface

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

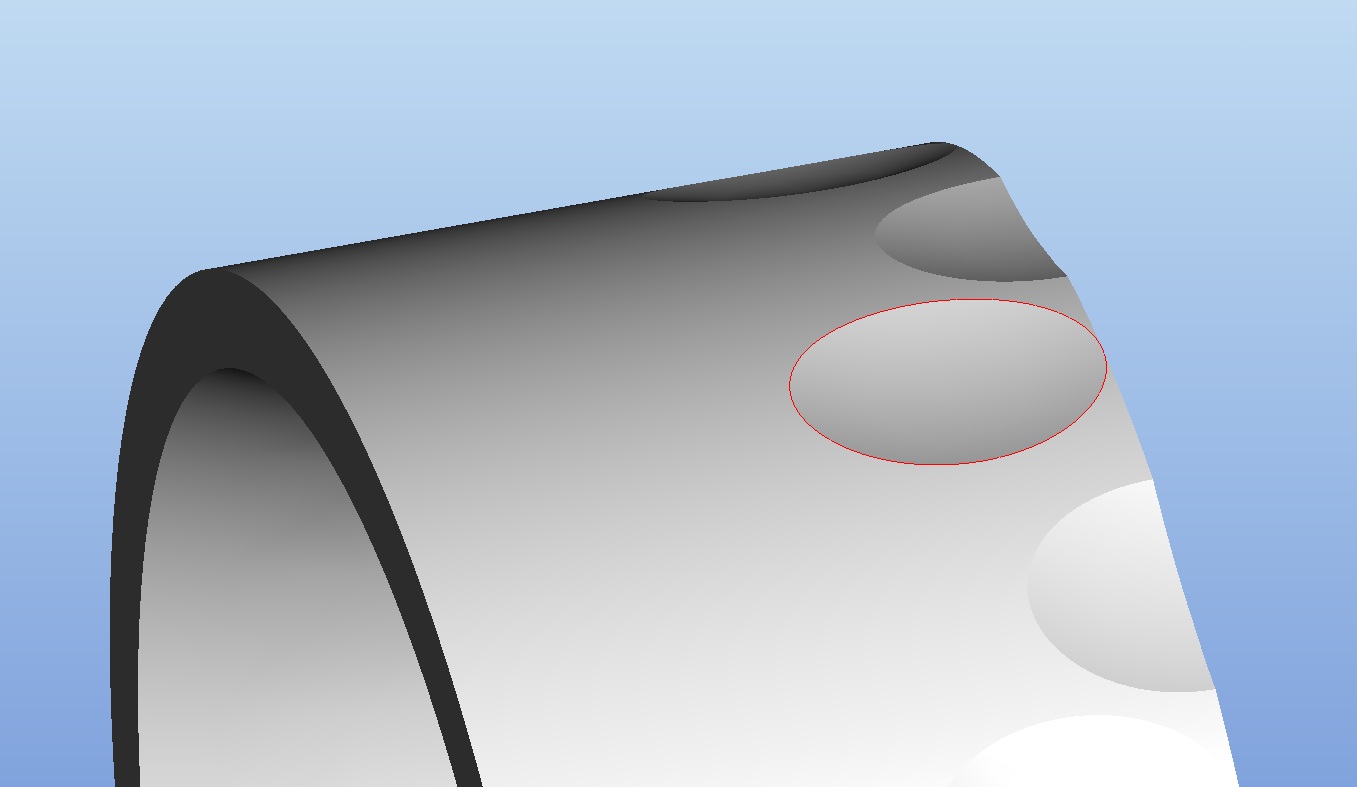

Creating a round dimple on a round surface

I don't mean to flood the forum but I'm stuck again. I'm trying to create a round dimple patterned evenly on the surface of a ring. As the diamter of the dimple get's larger, the shape turns more and more into an oval instead of a true circle. Any clues as to how I can compensate for the curve of the ring to get a true circle on the face instead of an oval?

Thanks

- Labels:

-

Surfacing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Christian,

Are you sure you want to do what you're trying to do? To create a dimple that has a spherical surface AND creates a round intersection with the cylinder is actually physically impossible. If you want to do some complicated surface modeling you can create something that may look like what you want, but it certainly won't be easily machinable. (If you're molding it, that's a different matter.) You could sink a straight end mill into the part, then use a form cutter or a lot of passes with a small ball mill to create a dimple below that, but I think the elliptical edge dimple is probably going to be the easiest and aesthetically best version.

David

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am machining this and I thought about that right after I posted this. I can't think of any other way besides a ball nose end mill and doing that will create the problem I'm encountering. Maybe I'll just have to reduce the diameter of the dimple to a point where it isn't as noticable.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, not quite true. The reason it's elliptical is the the cut isn't deep enough to have the full diameter of the cutting tool go below the surface of the cyllinder in the cuved direction. But, when that happens, you'll also get a short cylindrical surface on both sides in the cylinder's axial direction.

Sounds like you want to have your cake and eat it too. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

To me it seems like a visual issue, if you want it to look like your concept revolve the elliptic cutter that makes the shape you want visually. Then use the machining procedure that will create a smooth surface...?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You could do that but with the amount of dimples on the ring the machine time wouldn't be worth it.