Community Tip - Need to share some code when posting a question or reply? Make sure to use the "Insert code sample" menu option. Learn more! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Cut layers in a sub-assembly

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Cut layers in a sub-assembly

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Cut layers in a sub-assembly

i have a questions about addeding sub-assemblies i hope i can explain my thoughts correctly.

If i have a top level assembly and i want to add my keyswitch assembly into it. currently i would on the part level create the proper cutout and then on my top level assembly, assembly my keyswitch sub-assemly into this location. I would like to work more of a top down approach.

i'd like to make all my sheet metal parts (blank, i.e. no cutouts) assemble them together. then on that top level bring in my key switch sub assembly and place it anywhere i'd like and it put in cuts in at that location and also have that drill down to all part levels and add those cutouts so i can dxf out those lower level parts.

Best way i can explain it is that the sub-assembly for the key switch would have all the parts and pieces so i can create the proper bom BUT also have cutout info in it so when i place it, it also adds the cut feature for correct hole size

- Labels:

-

Assembly Design

- Tags:

- modeling

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can create assembly cuts and have the cuts show in the piece parts as an option.

The trouble you can run into is that the dimensions for that cut are contained in the assembly so the piece part will not have related dimensions in it.

I would recommend against this as any other use of that same part will drag the assembly with it along with the cut.

I would recommend keeping the cut at the assembly level and creating a simplified rep of just that part so that a separate detail of the part could be created for the DXF. This preserves the related cut dimensions with the part if that is required.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

thank you for your reply.

i know i can make assembly cuts. But that's not what i'm after, when i bring in my parts (keyswitch assembly) i want the hole cut to come in with it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, you can make a UDF in an assembly that contains the key-switch assembly component and the cutout feature that is referenced to this key-switch geometry, and perhaps the rear-surface of the panel which specifies the cutout's depth.

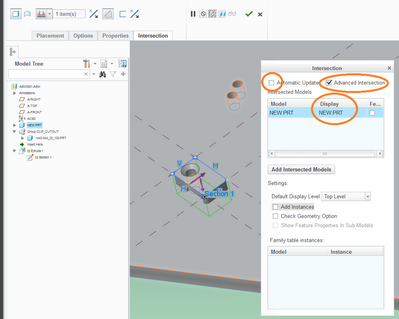

I think you'll still have to tweak the "intersection settings" of the newly placed cutout (unless you don't mind it being "automatic").

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

i tried adding the cutout to the assembly but didn't seem to come in when i assembled it in. the extrude was there but never cut the the part i needed it to

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

i know they can do it with intellegent fasteners on creo 3 and 4 so it should be able to be done with anything just not sure how it's done. we won't be going to creo 4 till next year (currently creo 2)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Intelligent Fasteners is a separate application - so obviously this type of automation can be done by programming, but with the out-of-the box modeling tools, I think your only choice is defining a UDF. It doesn't matter about the Creo 2 version - UDF is a core functionality that has always been around. I just want to make sure we are on the same page.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

yes i have UDF's and i know i can do a top down approach with them but i was hoping to try to get it to work with a top level sub-assembles item and when i bring that in the cut info would come along with it. Doesn't seem like it will work the way i'd like.

thanks everyone for your help. if anyone has any more idea's let me know thanks again!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

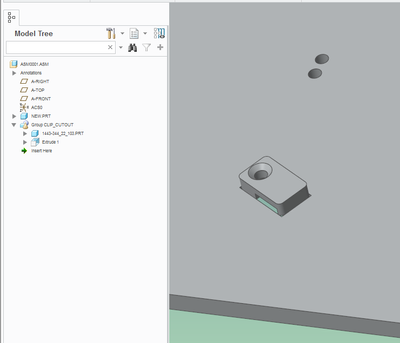

Well, it worked well enough for what I tried. Sure, UDF didn't automate everything - but 95% is still a time saver...

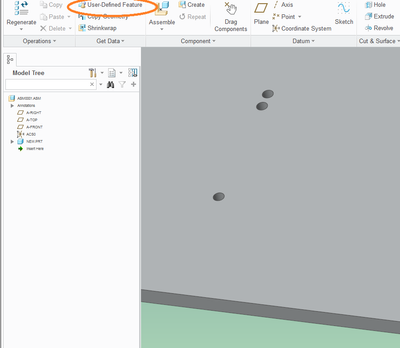

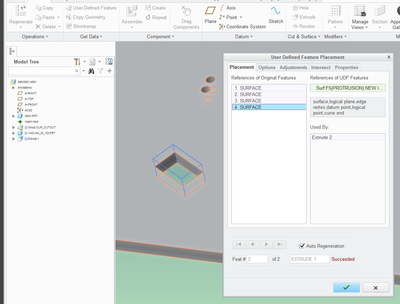

That 5% was the relatively easy task of re-defining the extrude feature that does the cutout and changing from "automatic" intersection to manually specifying the parts that will be intersected. In this example, a UDF was created that contains a clip component and an extrude feature that defines the cutout. Note the sketch geometry of the cutout depends on the geometry of the clip:

The clip part needs 3 references to be placed (the top face of the panel, cylindrical surface of the screw-hole, and the edge surface of the panel to establish clip's "clocking angle". The 4th reference is required by the extrude feature - it specifies its "depth of cut":

Is this kind of workflow useful to you? You have to weigh the time savings of getting most of the repetitive work done for you vs the time to set up and maintain the UDF...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It's not possible for Creo to add a feature when you assemble a component. At least not without customization.

There are a lot of user doing extensive customization and automation but the time investment would be significant I would expect.