Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Cutout in assembly does not update correctly i...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Cutout in assembly does not update correctly in family table members

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Cutout in assembly does not update correctly in family table members

I am using Creo Parametric - Release 4.0 (connected) 4.0 M140

I have an assembly with two parts (X & Y) part X is used in a family table. Part Y is assembled to X using datum planes in part X that are set to rotate 180° in part X's family table members. The planes and model Y rotate 180° correctly in the assembly but the cutout created in the assembly of X & Y is not rotated in the family member (changes to part Y appear in the cutout but the defined rotation does not happen). This worked very well in previous versions and works in 4.0 IF the cutout was created in an older version. If the cutout is recreated in 4.0 it does not work.

Added zip file with model example of 4.0 behavior.

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

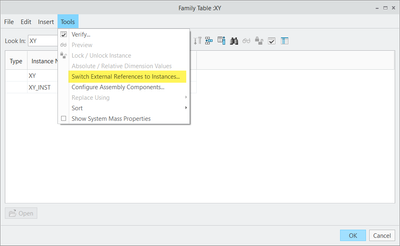

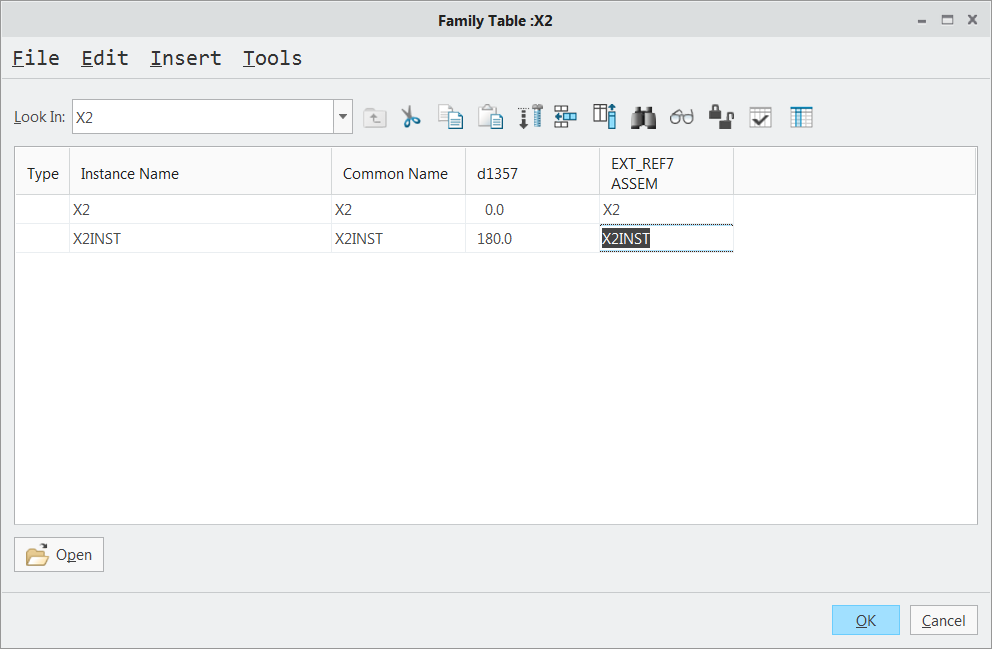

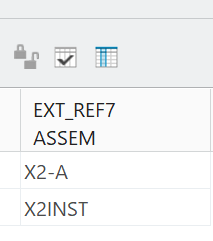

I have found the resolution to this issue. There is an option within the family table UI to switch external refs to instances. This results in the merge/cut out updating based on the assembly instance as desired.

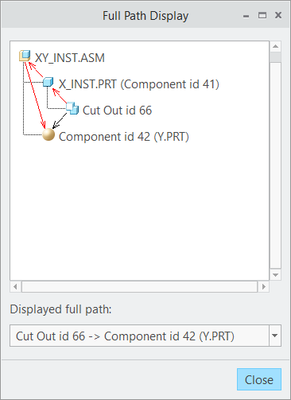

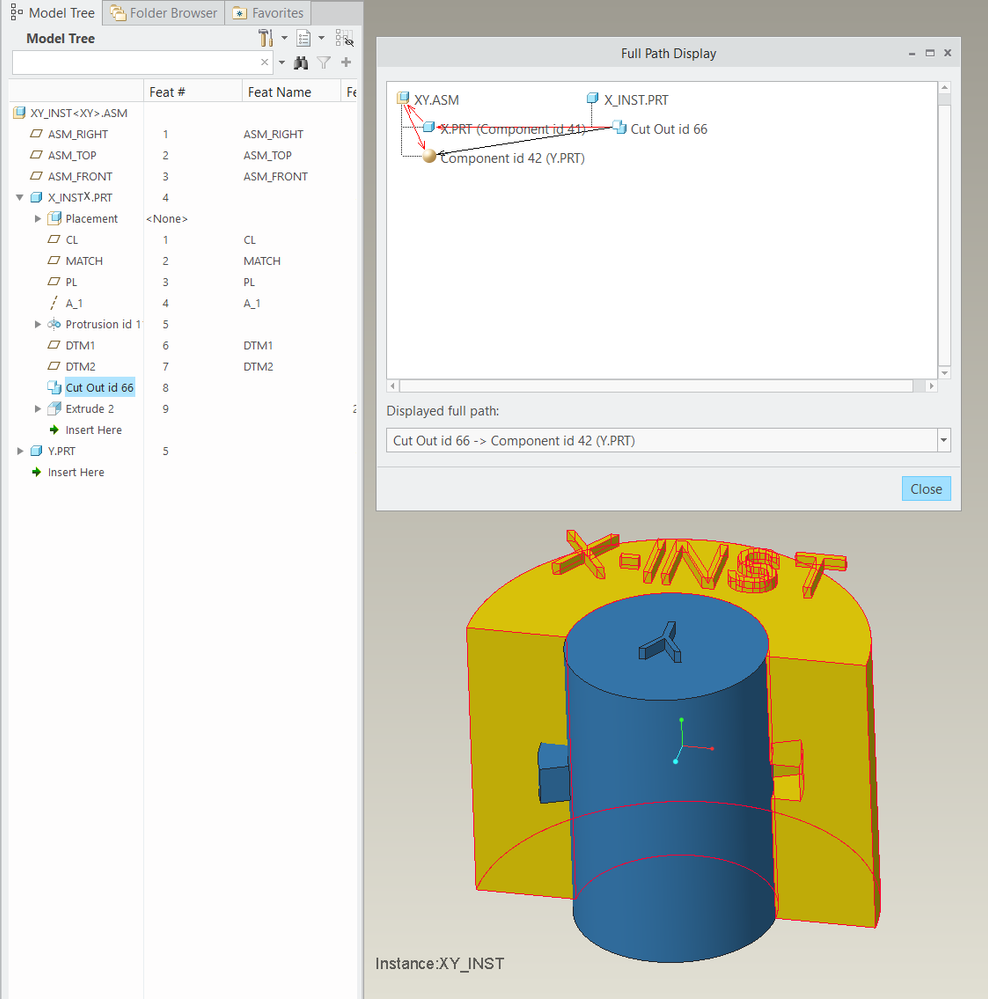

This results in the following reference graph from the GRV where the cutout is now driven by the assembly instance as desired.

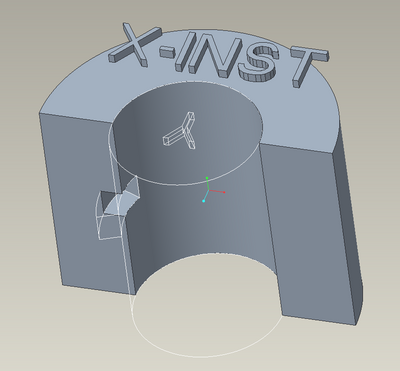

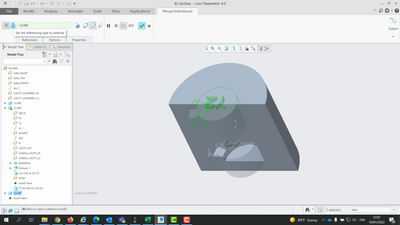

The cutout in the assembly instance.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Have not figured out the root cause yet but there are some indications that the models are not reflecting your design intent. I have not seen any circular reference warnings or .crc files being written which is good.

But...

Creo 4 M150.

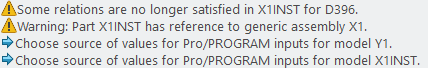

Warning message presented at the command line:

•Warning: Part X_INST has reference to generic assembly XY.

This message suggests that the reference to the generic instance of the assembly is why the cut out is not rotating. It appears that the cut out is regenerating using the position of component Y in the generic instance of XY.asm. This is consistent with the state of the models when regenerated but not your design intent. It should reference instance XY_INST.asm to locate the coutout accurately.

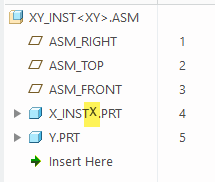

Glyph in model tree indicating something, It is similar to failed regen but not an exact match. This is the part with the merge/cutout so it is suspicious. Does anyone know what this X superscript glyph indicates?

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

you are misunderstanding the issue. Hopefully the following helps.

Normal direction of PL plane is the same in all instances. Dtm1 and Dtm2

are the controlling planes of part Y. They rotate 180° in the XINST part

causing the Y part to rotate (this is desired) however the cutout does not

rotate as it should.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

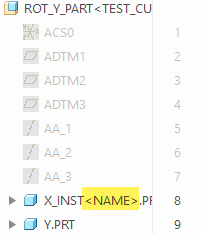

The suspicious looking glyph is not a glyph. It is the grater than/less than symbols placed around an instance name. I don't think it is displayed correctly in this case. I renamed the generic model from "X" to "name" and then it becomes clear as seen below.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is the reference viewer graph (Creo 4 M150) of the merge/cut out feature in the XY_INST.asm. As you can see Creo is showing that the cutout is driven by the generic XY.asm hence the position is not updating. The cutout would have to be driven by the assembly xy instance that has the rotated part Y.prt. The models reflect what is documented by this graph. Can you check the reference graph in Creo 4 of a model set that was created in an earlier version (3-) and compare it to see of the references are different than shown here?

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have found the resolution to this issue. There is an option within the family table UI to switch external refs to instances. This results in the merge/cut out updating based on the assembly instance as desired.

This results in the following reference graph from the GRV where the cutout is now driven by the assembly instance as desired.

The cutout in the assembly instance.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you tbraxton!!!

I have several "master" models, assemblies and drawings that were initially built with ProE 11 (year 1994)?? or there abouts and have been utilized, updated, modified thru most of the iterations since then including Wildfire 1, 2, 3, 4 and Creo 1, 2, 3 and now working in 4. Many of the features have been recreated in one or more of the newer versions without issue. This is one of the few times things to not work nearly as well (as expected to work). This method of cutting out a part using another is a feature that is always present in these "masters" but recently increased complexity of the part used to make the cut has caused the cutout to fail. Remaking the cut in the current version (Creo 4) seems to solve the failure but lead to this failure to rotate the cutout in the instances. Again, thank you so much for the assist!!!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

older versions.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you can get me an example of one that is not working, I will review it. I of course need to understand the design intent that is not regenerating correctly to help investigate.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Here is an example of one that does not work. Both parts were originally

built in versions older than Creo 4.0. The intent is for the cutout to

rotate 180° in the instance. F.y.i the previous example was all built in

Creo 4.0

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I do not see a new model attached to your latest post.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

not be the correct method.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

It does not regenerate correctly in Creo 4 M150. I did note that the structure of these models is not identical to the test case you initially posted.

Have you verified that this set of models behaves correctly when retrieved and regenerated in Creo 3 or earlier? I suspect that it may not based on what I am seeing but you should confirm that. It is possible that this is a bug. The first test for that will be to confirm that these models regen correctly in an earlier release of Creo or Pro/E.

The constraints of this model set are not identical to the Creo 4 test case you posted earlier. This may or may not be relevant but introduces additional variables. The clocking angle for Y is controlled by a relation in the generic assembly is only one if the differences I noted. There is also Pro/Program involved in the regen, I don't think it is an issue in this context but does convolute the debugging.

Your parts use matched absolute accuracy (this is good) but the assembly is relative accuracy at the default value. I have seen mismatched accuracy cause problems with external refs features such as merge/cut out. The cut out feature is completed in the assembly the way the models sit now.

When I regenerate this assembly family table with the external ref options active there are several warnings shown when regenerating the instance X1INST.asm. The most relevant in this context is that X1INST.prt has a reference to the generic assembly X1. As long as this is the case it is not going to follow the behavior in your earlier test case.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

structure is different as these are stripped down versions of the "master"

models and parts that I'm trying to get to work with a cutout made in Creo

4.0 vs. a cutout made in earlier versions that behaves as I need it too.

The first models sent were totally new built in Creo 4.0 to test whether or

not it was an issue with models being built in older versions. That seems

to have proved out to be the case. However the cutout if kept from the

older versions does work as needed but sometimes fails when the controlling

model becomes complex. I am trying to improve the performance of the

cutout.

I will strip out a master leaving the cutout from the older versions, if

you will, please review that and see if it can be determined why it works

but when a new cutout is made it does not.

Looks like I need to rectify the warnings first in the just sent models.

Deleting all of the ProProgram hopefully will accomplish this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

tbraxton

The attached model is made by stripping down the current master. Setting all accuracies to absolute .00015 and keeping the cutout made using older version that rotates as needed (lower part/cutout). A new cutout has been added using Creo 4.0 that does not rotate as it should (upper part/cutout), this new part/cutout uses the same assembly planes to control rotation. Something odd about the new cutout, the part used to make it when rotated in the instance has a visibility issue of the lug in the isometric view, I do not know why. The lug appears fine in the lower (older version) part when rotated

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have reviewed and tweaked a few things on this latest set of models. It is not working as it should, I strongly suspect that it is a bug. You should open a case with PTC support, Creo 4 is not officially supported at this time, but force them to address this as core functionality requires that legacy models regenerate correctly in newer releases. You can try it in Creo 7 or 8 and if it still fails then that will strengthen the severity of an SPR if one is filed.

There are workarounds but they will require effort on your part to restructure the models.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

wondering why this method worked in the past but not now. Will try this in

newer releases first. Hopefully the UI of the new is intuitive and easy to

figure out.

Almost afraid these masters need rebuilt (ugh, some have several hundred

lines of relations and ProProgram entries.)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

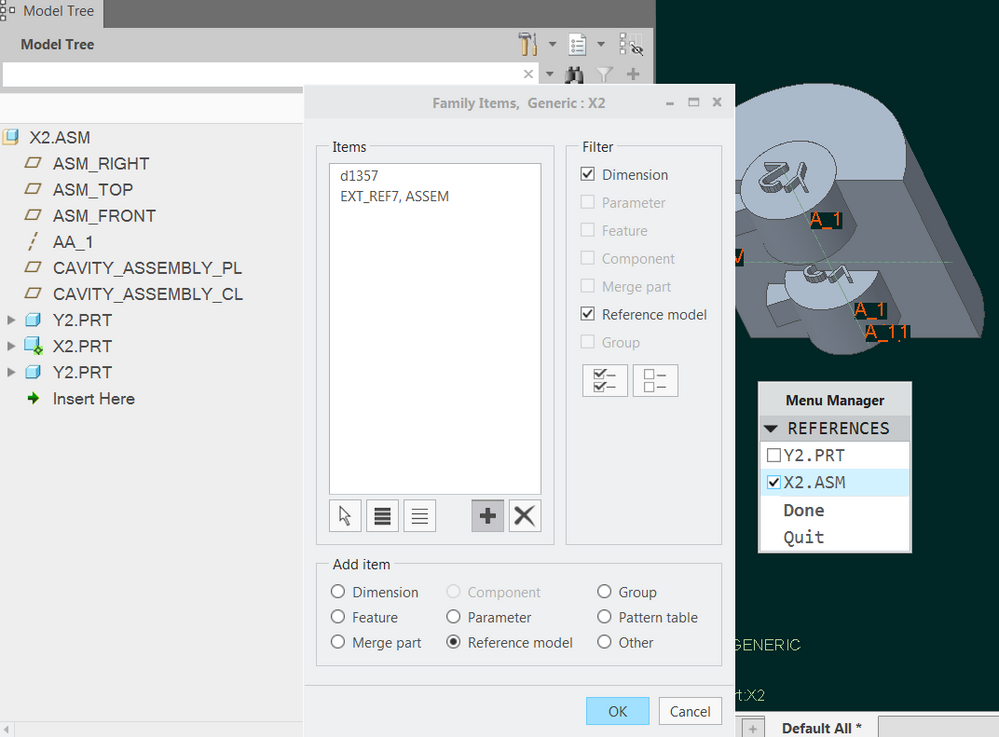

Hi @MT_WashPA , I don't know how things worked at your company before, but I strongly recommend that your X parts should have the "ref. model" column in their family table. Otherwise, how would Creo know what context to use when regenerating the cut-outs? Anyway, the UI shortcut function pointed out by @tbraxton (switch external references to instances) does not seem to work to "fix" your x1 and x2 parts in the .7z files provided in this thread.

However, using this procedure does make your test drawings look correct (x2_PTC_HELP.7z data used in the example):

1) activate the X2 component in your assembly X2.ASM

2) edit the family table of this component

3) add the "Reference model" column, and specify the X2.ASM as the model

4) specify the correct context for other instances of X2 - for example:

5) accept the changes to the table, regenerate the drawing:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi pausob,

Adding the reference model column helps the situation but requires the models to be manually regenerated when drawing is retrieved for the rotation to take effect. Looks like now an "auto regen" function needs to be added for family table instances upon drawing retrieval. I have not seen that option available. Do you know how to accomplish this? I am doing some more searching now for this now.

Thanks for the assist

MT_WashPA

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, pausob

Pretty sure I have found the solution.

1) Adding the reference model column per your suggestion solved the non-rotation of cutout created in Creo 4.0

2) Making the assembly family table control the 180° rotation vs. having the assembly relations reference a value from the part instance removed the need to regenerate the drawing/models after drawing retrieval.

Thanks for your assistance.

MT_WashPA

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I'm glad you found a working solution. To be honest, figuring out the structure of these models gave me a bit of a headache at first - what is driving what? 😁

I suppose it's always a bit of a detective work to examine other people's models so I do not know whether controlling the component's angle directly in the assembly family table is the way to go. Seems you now have to manage columns in 2 tables. Anyway, maybe doesn't matter much - these parts and assemblies are very intertwined; However, I do wonder if the regeneration is necessary if you verify all the family table instances (assembly and the X part) before saving them and then saving the drawing. That seems to work on my system and the saved drawing (x2.drw) is retrieved without regenerating anything...

(it does take 2 regenerations for everything on the drawing to update if I change the angle d1357 in the family table of x2.prt)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, pausob

Thank you so much for your assistance!!

Fortunately the rotation of the Y2 part will always be 0° or 180°. I looked at using the rotation angle from the planes in assembly to control the part's planes, but the assembly generic and instance have different session id's and I do not know a method to use the same relation but with different session id's in relations. LOL, this may have been all or part of the problem from the get go. The assembly relations used the rotation angle from the part, BUT IT WORKED if the cutout was made in older versions. Oh well, this will fix those issues and should improve function (ie. reduce failure rate of cutout when the Y2 part becomes complicated).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

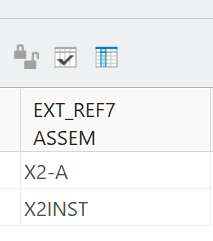

below are the screenshots missing in the previous reply.

*added -a to both the generic and the instance name*

*the assemblies generic name updates in the parts family table but the

instance's name does not.*

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

parts family table works but the instance name in the family table does not

update if it is renamed.

[image: image.png]

*added -a to both the generic and the instance name*

[image: image.png]

*the assemblies generic name updates in the parts family table but the

instance's name does not.*

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

below are the screenshots missing in the previous reply.

*added -a to both the generic and the instance name*

*the assemblies generic name updates in the parts family table but the

instance's name does not.*

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yep... not unexpected; though it would be nice if the system would do this renaming for you for family tables of in-session objects.

It's just one of those things one has to consider when using family tables...

I can see how this was a lot simpler with the older cut-out features which do not seem to need the extra column in family table and also regenerate right away after an assembly change.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Wow, great job of explaining this! One thing to note, the datum planes

being rotated in part mode are not the planes used in assembly to control

the rotation of the Y2 part and cutout, I missed removing those from the

model. Those are used to control the rotation of other features that

reference the revolved cutout (note the two different "D" numbers in the

assembly and part family tables).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello @MT_WashPA

Even though post is now closed, I took some time to look at it this morning.

The first Cut Out id 32114 of X2.PRT:

- was produced in an old Creo Parametric version (One Pro/ENGINEER version which was still calling Menu Manager - visible upon Edit Definition)

- was producing behavior you wanted

- But this behavior was nevertheless NOT expected for the following reason. >Info >Reference Viewer => Show >Dependencies on it was highlighting:

- Dependency to Y2.prt

- But NO DEPENDENCY to X.ASM

=> There was therefore no reason to produce an outcome depending on the way (placement constraints) how Y2.PRT was assembled in the generic assembly

=> This cutout should therefore have produced the same geometry in all instances of the given generic assembly (taking definition ONLY from Y2.PRT, and not on the way how Y2.PRT is assembled in the context of X2.ASM)

The second Cut Out id 225192 of this same part X2.PRT

- Is produced in a recent version of Creo Parametric

- Does NOT produce (per default) what you want

- And this is nevertheless expected from a technical standpoint, because >Info >Reference Viewer => Show >Dependencies shows dependcy on Y2.prt (of course), BUT ALSO FROM X2.ASM (the generic)

- Therefore:

- Without additional level of definition, it is expected now (in contrast which was proposed in old Cut Out Features) that part instances called in asm instances refers to this generic X.ASM (and therefore in the way how Y2.PRT is assembled in this context)

- And to avoid this, you need an External Reference definition to X2INST.ASM in the scope of the part family table, referring to Assembly Instance name, as @pausob already pointed out (Thanks a lot for this!!)

Additional info: Related to that, if the second Cut Out Feature is redefined, and then switched to External as follows:

=> Dependency in Reference Viewer lists then ONLY Y2.PRT (and not X2.ASM anymore, like the old Cut Out Feature)

=> But this information is now correct, which means that the cut out, in the "external definition context" is now really completely independent from placement constraint & Orientation of Y2.PRT (not what you want in this context, but "Reference Viewer" information is now reliable and correct)

Therefore, in short:

- You absolutely need this External Reference Configuration in part family table for the wished instance (pointing to correct assembly instance name)

- This is officially documented in Tip: Adding Reference Models section of our Help Centers as follows:

Refer also to those examples here confirming this approach as recommended to be in supported conditions (there is no material for a SPR on the new Cut Out Features behaving now as expected. The old Cut Out features, even though were proposing a solution you were happy with, were nevertheless not consistent nor reliable in term of dependency information in Reference Viewer)

AN evidence tha old cut out feature was incorrect (whereas new one is correct now) can be demonstrated as follows (shown in Old_versus_New_Cut_Out_Feature.mp4 attached movie):

- Delete the entire Asm Family Table

- Edit dimension of CAVITY_ASSEMBLY_PL (Assembly Datum Plane) from 0 to 180 degrees

- Observe that Cut Out is incorrect for the old Cut Out Feature, whereas it is now correct, expected, and reliable for the new Cut Out Feature

Now if my understanding of your last post is correct, you're looking for a way to avoid:

- defining external reference to asm instance in part family table

- using Assembly Family Tables (just using Part Family Table, and call X2 generic or X2INST instance, based on a paraeter value driving orientation of Y2.PRT)

If my understanding is correct, you may want to drive this with good relations and correlated Pro/PROGRAM definition.

=> Way to do this is hlighted in second attached movie named Alternate_Technique_Without_Assembly_Family_Table.mp4

=> Outcome of this movie was backed up, and uploaded in the third attachment

Hope this helps to have a good understanding of the background, and to propose a solution which may fulfill your business needs without requiring usage of Assembly Family Tables.

Regards,

Serge