Community Tip - Did you know you can set a signature that will be added to all your posts? Set it here! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Need help with creating surfaces from multiple...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Need help with creating surfaces from multiple sketch lines.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Need help with creating surfaces from multiple sketch lines.

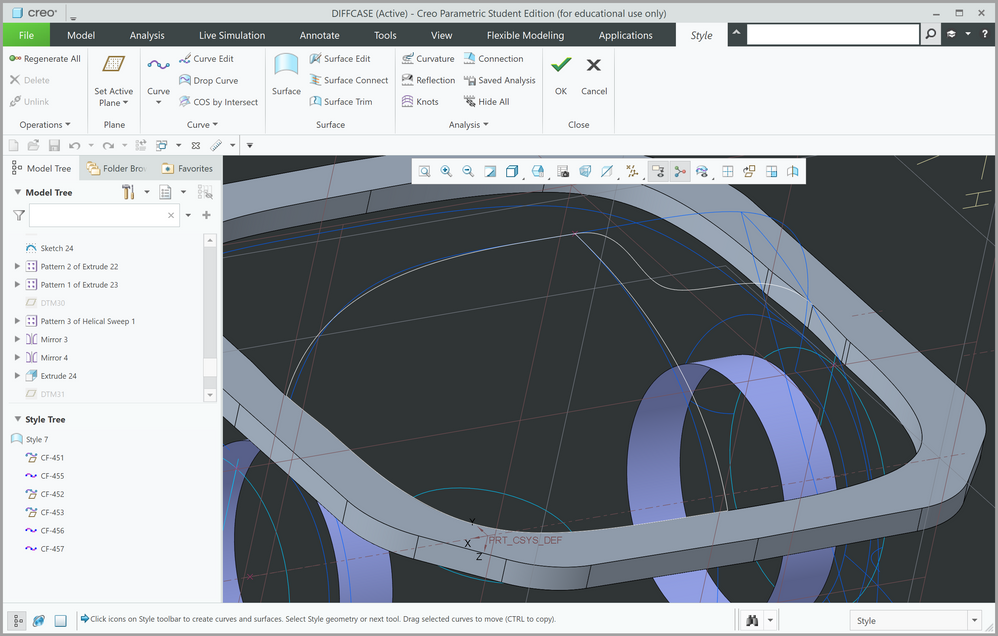

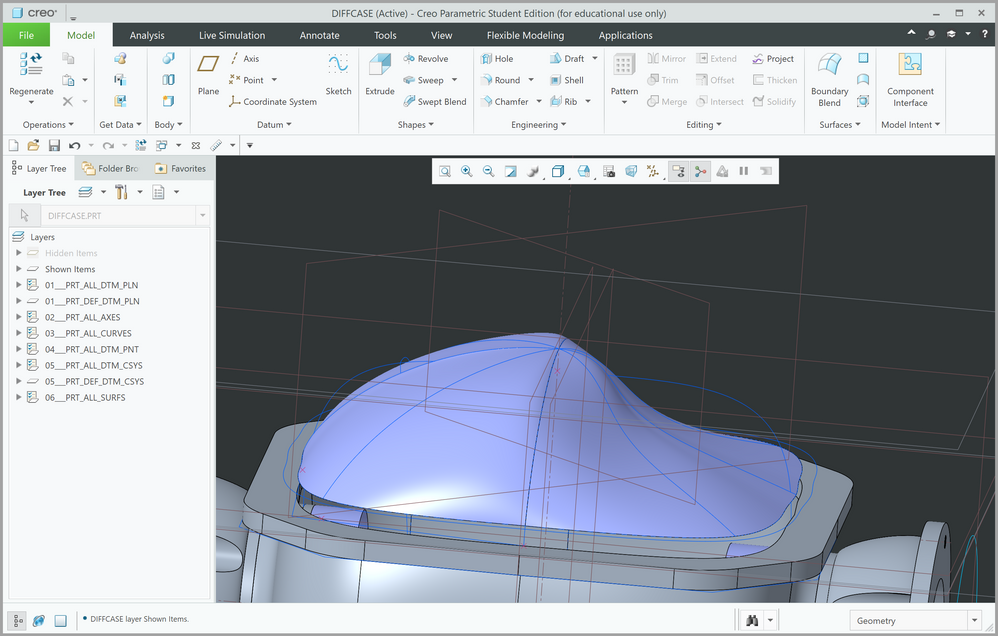

I'm making surfaces in creo right now but I'm having trouble because the sketch I used to create the extrude to which the surface connects to was made with multiple lines. Thus when I create a boundary blend or surface I'm unable to create the surface because it is not continuous.

If you look at the image you can see the surface is incomplete because the curve used from the extruding was from a sketch with multiple lines. Is there a way to merge lines, or project the lines all as one, or create a datum line along the edge?

I'm using the style tool

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

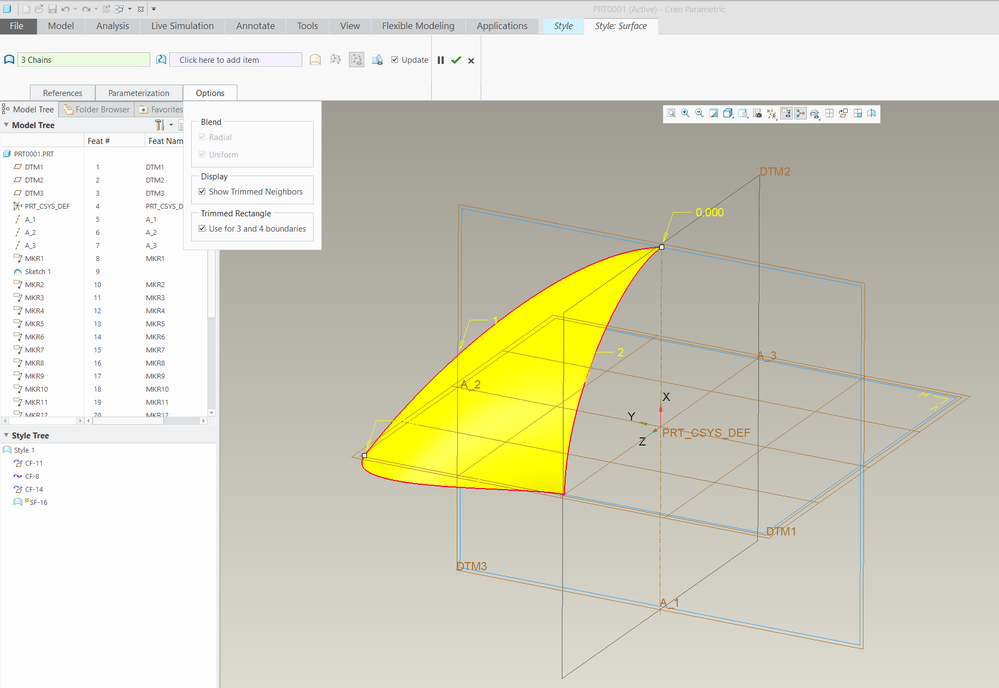

Creating a 3 sided surface is not a best practice using boundary blend or ISDX. If you are going to do it, I would strongly suggest using ISDX and selecting the option to create it using a rectangle which is trimmed option. The software will create a 4 sided surface and trim it for you. It is under the options tab in ISDX as shown below.

Create two 3 side surfaces using the same curves and build it both with and without the trim rectangle option and look at the offset mesh and Gaussian curvature to observe the difference.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

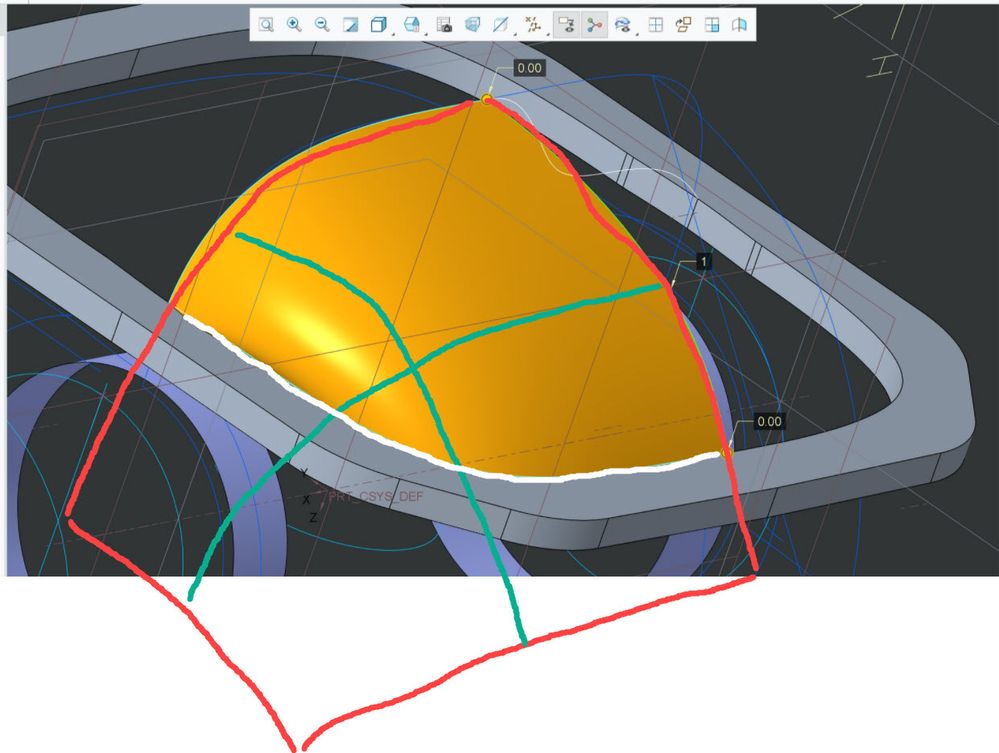

I will get to the curves question. It looks like you are attempting to build a surface that is 3 sided, that is not a good idea. You should build a 4 sided surface and trim it to achieve the 3 side shape shown in your pictures. It also appear you are using 2 boundary curves with an internal curve in your last picture which is not a good way to create this geometry. If you get it to regenerate successfully it will almost certainly not offset to a thickness if needed downstream. Look at the Guassian curvature if you do create it and look at the pointy vertex corner of the surface. Connecting anything to that boundary will also likely be problematic.

For style curves you should directly build the 4 external boundary curves and then add internal curves if needed to control topology inside the boundary. These curves can be built with core Creo features or Style curves and can be mixed in surface construction within style features. When selecting the curves you can use the selection paradigms (chains, loops etc.) to combine/trim curves to define the boundaries. If you are not familiar with this refer to the Creo quick reference card for selection tips.

In the picture immediately below a concept for a curve network to create your geometry is shown. Red represent the 4 boundary curves, green are internal curves should they be needed and the white shows the curve to trim after the 4 sided surface is built. In your case it looks like the flange is planar so you can trim the surface with a plane to get your 3 sided surface quilt and you would not need to create the white curve. I do not think you need the green ones either for you geometry. You also need to pay attention to curve connection and continuity in anticipation of joining other surfaces needed to create solid geometry and thicken it. Take this as a general approach to get a 3 sided surface as matching the opening in the flange is probably not going to work using a single 4 side surface because of the fillet in the corner.

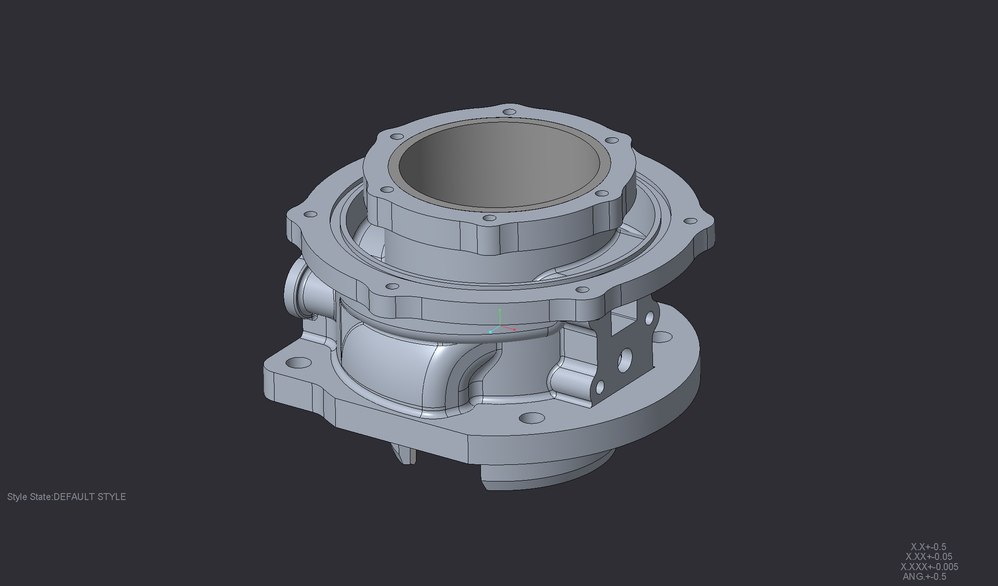

I am speculating the this is a gear differential case design that will be machined or cast based on the file name. Unless you are trying to learn to use style features I would suggest using core Creo features to get the case geometry. I have designed machined and cast gearboxes and would not choose style features as a preferred tool to create the general form for that type of design. If you can get the geometry with core features it is usually more straightforward and easier to control the design intent in the model without style features. You can parametrically control style features but it requires more construction geometry and planning of the design intent to make it useful to modify models.

The picture below is a simple example of a cast & machined cylinder design that is water cooled and has internal water passages as well as the porting passages for combustion, all built without using style features. You can get pretty complex topology using the core feature set.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

here's were I'm at, definitely my biggest road block I've had in Creo, been working on this issue for many hours

Yes three sides doesn't thicken so I tried what you suggested but I can't get the surface to meet the curve that I would use to trim as seen above.

also for this particular part of the build it includes wavy curves that (I don't think) aren't obtainable with core features.

-Michael

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In order to offer more insight would need to see the objective of what you need to design with enough of the surrounding detail to make a plan for how to model it. I see you are using an educational license and I don't think I can open your files using a commercial license.

If you want to post some images (could be hand sketch) and/or try exporting a STEP file which I think I may be able to open I will take a look at it when I get some time. I need to see the final form you need to create with these surfaces ideally with enough dimensions to be able to create it. Obviously if you export a STEP file that will define any of the geometry exported so I would need an image of what it should look like when done.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

So I did some testing and I figured out:

when a surface in the style tool has three sides you cannot thicken it unless it has no curvature.

when using the boundary blend tool, a three sided surface can be thickened.

I think the tools work in different ways because surface uses interior and exterior curves while boundary blend uses direction of the curves.

here is the general shape (minus all the lumps) I created this all in one action with boundary blend and it does thicken.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creating a 3 sided surface is not a best practice using boundary blend or ISDX. If you are going to do it, I would strongly suggest using ISDX and selecting the option to create it using a rectangle which is trimmed option. The software will create a 4 sided surface and trim it for you. It is under the options tab in ISDX as shown below.

Create two 3 side surfaces using the same curves and build it both with and without the trim rectangle option and look at the offset mesh and Gaussian curvature to observe the difference.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

so I've created the surface with the curves going longitudinally and laterally instead of converging into one point; however, this did leave me with a three-sided surface on both sides. With the boundary blend tool, I created the three sided surfaces and in the middle I used ISDX. A mix that is probably really bad but it was the only way it worked. It created a thicken that I was satisfied with was is not great as it has seams and the general shape is a bit off from my original idea. I'm sure that I could improve it but my computer is not powerful enough to handle ISDX surfacing and I want to move on to other projects. However, I learned a lot that will definitely change my approach for my next projects that involves surfacing. Thank you.