Community Tip - Want the oppurtunity to discuss enhancements to PTC products? Join a working group! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- rpt.index question

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

rpt.index question

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

rpt.index question

Okay... so last time I was trying to work out how to get a repeat region to show the generic name of a family table instance rather than the instance name. I worked that out.

Another problem I had was using a part parameter I call "ITEM" which returns an integer, which I then use to order the parts in a BOM table of an assembly drawing. I've been told I can't do this anymore. Specifically the problem is when you have multiple assemblies with some of the same parts. I wound up having one out of 5 different product assemblies that had to miss component number 3 because it wasn't in that particular assembly. The table went 1, 2, 4, 5, 6, etc. Doc Control said, "Not Best Practice".

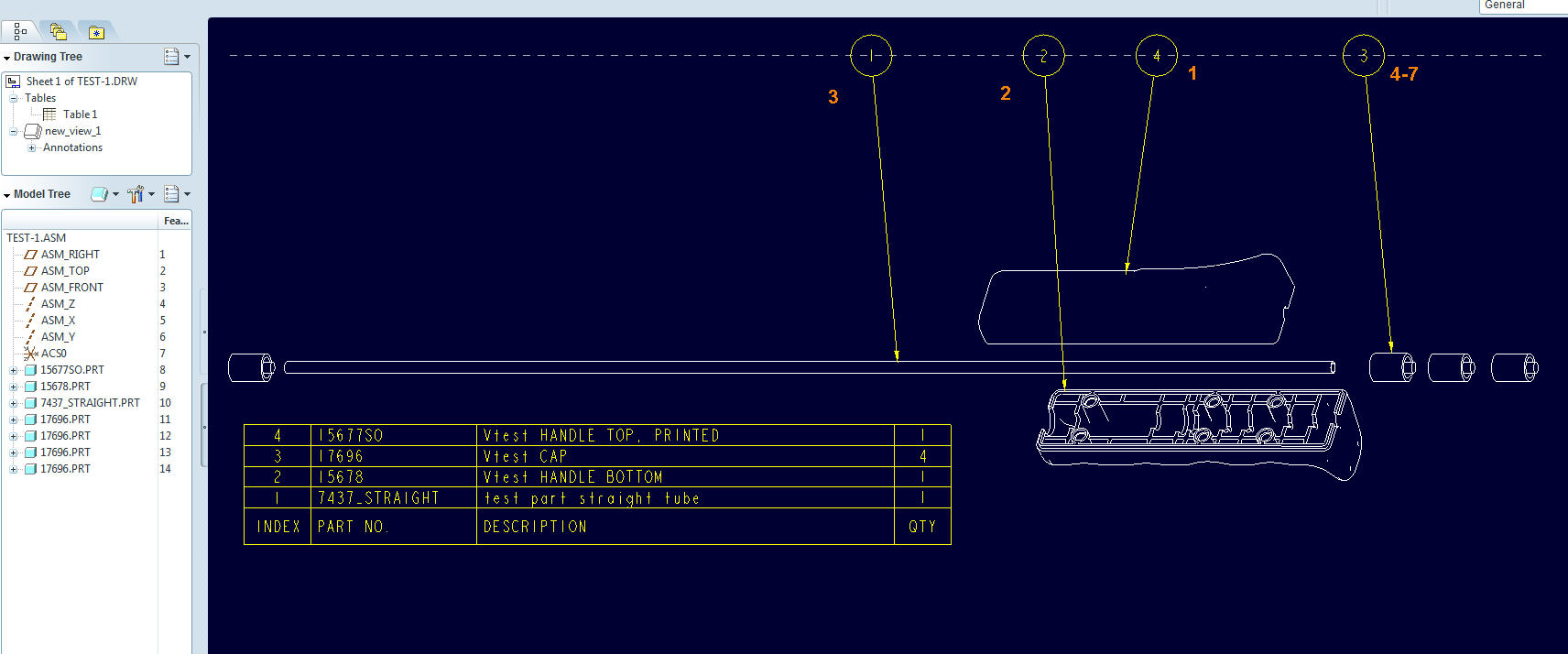

So, from this point on I will use "rpt.index" as the parameter numbering the components in a BOM table. But what I want to know is, how does rpt.index decide the order of numbering the components? See the pic below:

This is not the order of the components in the assembly. The numbers in orange represent what they would be if that was the case. Can I change this, or can I at least predict what I will get? I would prefer to be able to get the balloons to number left to right 1, 2, 3, 4, or failing that they would be numbered in some way I could predict, like order in the assembly. Note, I don't want to Fix Index.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

Solved! Go to Solution.

- Labels:

-

Assembly Design

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

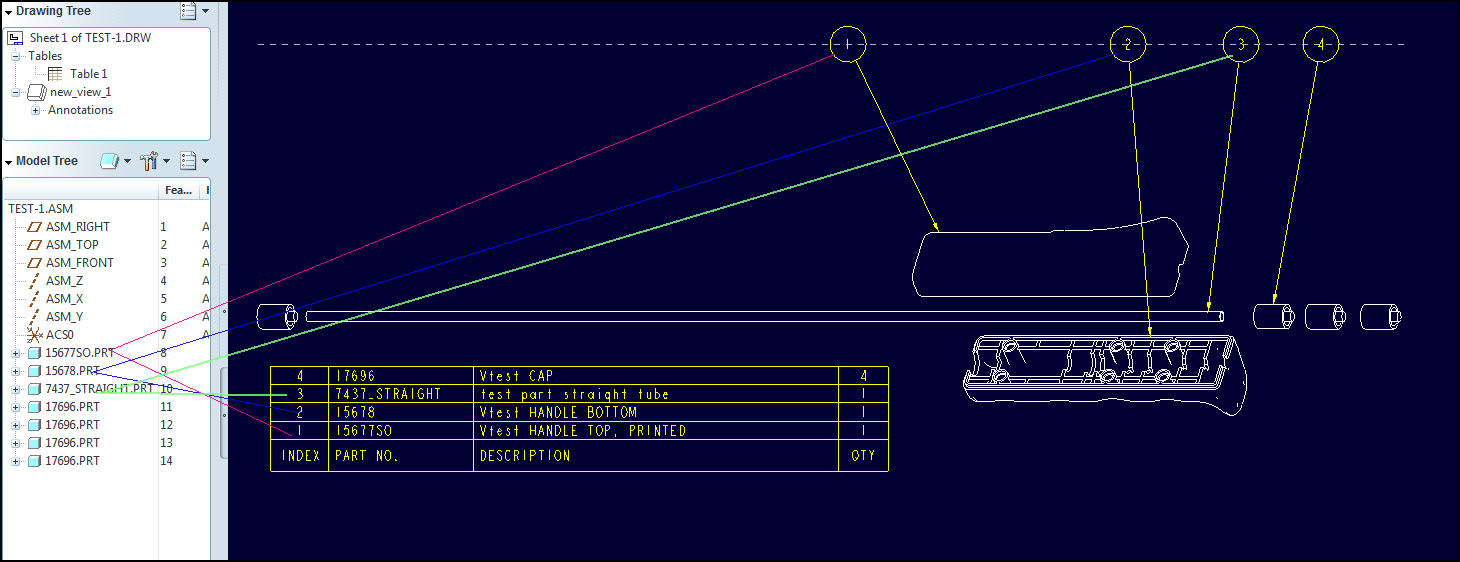

- when I set No Duplicates repeat region attribute then I get unwanted order

- when I set No Dup/Level repeat region attribute then I get wanted order

MH

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

- when I set No Duplicates repeat region attribute then I get unwanted order

- when I set No Dup/Level repeat region attribute then I get wanted order

MH

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you! That works.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Just as a side note, using fix index helps when you add a component and it "re-orders" your index numbers potentially causing confusion.

I almost always fix the indices of most of my repeat regions since our items numbers on the prints must match the item numbers in our engineering system.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

At this stage our manufacturing processes don't correlate with CAD models/sub assemblies and probably never will. By the time the drawing is released to our Document Control department then the drawing and assembly have been reviewed and approved to a Released state, so they can't be changed. To add a component I would have to Revise the assembly and drawing, in which case it will change anyway. In other words, it probably won't be necessary to fix index. Although there will probably be something that comes along that I can't predict which requires it.....

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fix index allows you to force the rpt.index to be whatever number you want that isn't already fixed elsewhere. You can also fix the entire table, if it already is in the order one likes.

It's not required when you have a simple assembly and are happy with the default order, but a lot of users coming to the forum will see the comments here and have more complex problems to solve. It mostly comes up when assemblies have a few hundred components and some of them get replaced and can't be assembled in the original order/can't have the original item numbers reused.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If you use a component parameter instead of a part parameter then the item numbers are assigned on a per-assembly basis, though this may not work perfectly for an assembly that is driven by a family table.

If you want to drive the order of components by some other characteristic (such as a component parameter), you can select the Sort option for the Repeat Region.

The cparam method allows the insertion of a dummy component, perhaps named "place holder" to leave a hole in the BOM table where a part is removed or is purposely skipped and unused, the latter particularly handy when other systems manage the factory floor and need to be filled in before the drawing is released and an assembly item is removed.