Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo+ and Creo Parametric

- Analysis

- EZ Tolerance Radial stackup problem

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

EZ Tolerance Radial stackup problem

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

EZ Tolerance Radial stackup problem

I use Creo Parametric 7.0.8.0.

I have a problem with EZ Tolerance extension, my problem is described bellow.

I was using set of a shaft and a bearring with a hole, firstly I calculated it by hand ańd then with EZ Tol., but the results were not same.

Here are my calculations:

1. Nominal Clearence

Hole-Shaft=(0.3760-0.3745)/2= 0.00075 mm

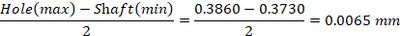

2. Maximal clearence

3. Minimal clearence

EZ Tol did the Nominal clearence good, but not the min/max clearence. (I attached some pictures with the assembly).

Thank you.

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I had to set Assembly Shift to Maximize and Attachment to CENTER-CENTER and then it calculated to be 0.00075 +/- 0,005750, which is right. Thanks anyway 🙂

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is it possible that your EZ tolerance setup includes positional tolerance and your hand calculations do not?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I had to set Assembly Shift to Maximize and Attachment to CENTER-CENTER and then it calculated to be 0.00075 +/- 0,005750, which is right. Thanks anyway 🙂

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator