Community Tip - Stay updated on what is happening on the PTC Community by subscribing to PTC Community Announcements. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Fastener with preload for 3 components

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Fastener with preload for 3 components

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fastener with preload for 3 components

Hi,

So I'm wondering what is the best method to fasten 3 components together and apply a preload? I'm running Creo 2.0 and I've had no issues using the advanced fastener tool with 2 components, however; I know that it cannot be used to fasten more than two components together.

I've done some searching, and using beams with a temperature load seems to be popular, however; I'm not exactly sure how to do this and constrain everything properly. I assume a round beam is to be created through the 3 components so as to simulate the bolt? I can do this without an issue, but I can't figure out how to "link" the beam with the temp. load.

Any advice, or other options, would be greatly appreciated!

Thanks in advance,

Scott

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

What defines how to, "constrain everything properly" depends on what you're after results wise and what you want the joint to capture physics wise.

That being said, the most basic method for doing it is to use a beam element defined by a curve, weighted-links to "connect" the beam element the relevant components, and then apply a temperature load.

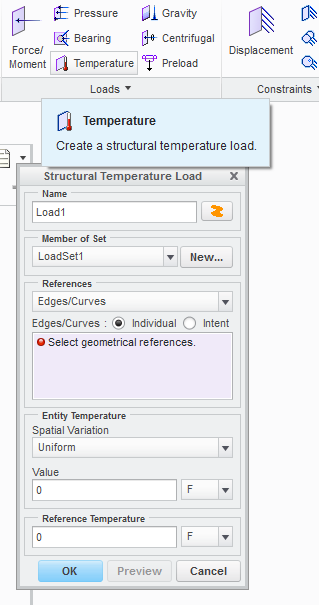

For the temperature load, you'll use structural temperature load (see image) and apply it along the curve you used to define your beam element. You'll need to play around with the total temperature change to capture the proper pre-load.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Charles,

Yes, the two holes would be where the bearings are preloaded. The forces don't act normal to the sketch, they act radially outward on the radius of both the cap and the bracket.

The fact that the contacts are frictionless seems to be the issue though. If I keep both interfaces as "contact" and just use some light springs, both caps spin around the bracket (normal to my sketch)

If I change one of the interfaces between the bracket and a cap to "bonded" then the caps stay in place as they should, with the exception of one of the caps being overly constrained.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Charles & Shaun,

I appreciate the help on this. I was able to use a combination of springs and a displacement constraint in order to get my simulation working properly.

Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Try using beam + contcts with infinite frinction and thermal load.

Preload is regulated by a force measure (as with fasteners)

I've used WF5.

Regards