Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- Analysis

- Modeling Fasteners through multiple parts.

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Modeling Fasteners through multiple parts.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Modeling Fasteners through multiple parts.

Hi, I have an assembly which consists of a circuit card assembly (CCA) and a EMI clam shell on each side of the CCA. The screw clamps the CCA in between the two clamshells. The fastener model will not work on this. I have tried "rigid links" etc, no luck there.

Is there anything else to try? I analyzed this model with all the parts fused together, and gives very high natural frequencies, etc.

Thanks in advance

- Labels:

-

Simulate

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

What version of Creo?

Are you using Windchill or another PLM for your model libraries?

Is this a stand-alone screw or family table member?

Are you trying to do this with Intelligent Fastener module?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello

1) CREO 2.0

2) Windchill.

3) Family Table

4) I am using the fastener model in Creo/Simulate.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

"...The fastener model will not work on this..."

why?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

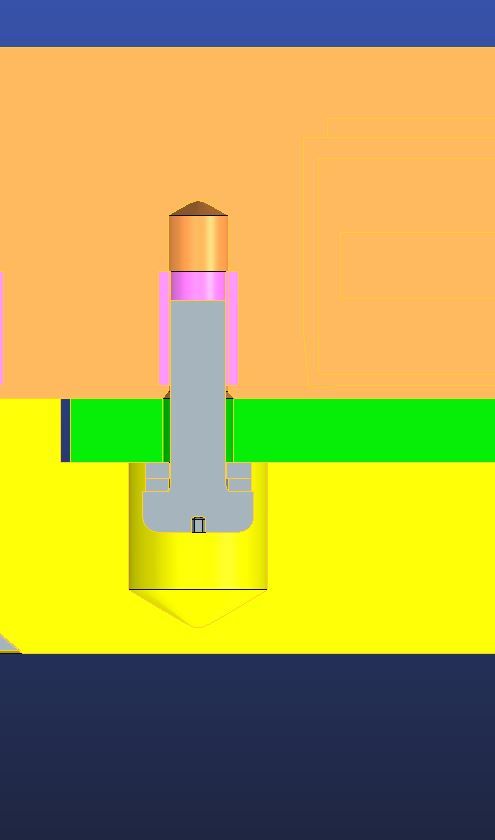

I am thinking there are issues with your model beyond just the way the fasteners are modeled. I use rigid links for fasteners in modal analysis quite often and they work fine for me. If your model-setup interface-default is bonded that may be the start of the problem. Look at the review-model showing the bonds/contacts/rigids. Try limiting connection areas using surface regions and interfaces rather than letting the model connect everywhere it is line-to-line geometry. For example make a region the size of the washers and only bond there between all three the parts. BTW The image you show seems like it should allow a screw fastener idealization. There are some specific ways the geometry must be made before it allows the fastener idealization, such as perfectly concentric holes, perfect cylinder holes (not tapered with draft) and screw (and nut for bolts) head plane perfectly normal to the hole axis. Your model geometry is probably fine, I just wanted to mention those restrictions.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello

Thank you for your input. The screw idealization will not work because it only works with the parts that are connected. The in between part is not affected. I like your idea of the ridge links between the parts. I think I'll try the rigid link idea first. Then the screw idealization between the two outer parts with the links for that preload and stiffness.

Thank you very much.

Rich Hilson

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Your welcome,

I do not see a sandwiched part in your image. I see the green part connecting to the brown in your image. The yellow is not shown as part of the sandwich, not even held by the screw. I agree that the fastener idealization cannot connect with a middle sandwiched component... I am just not seeing that in your model.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

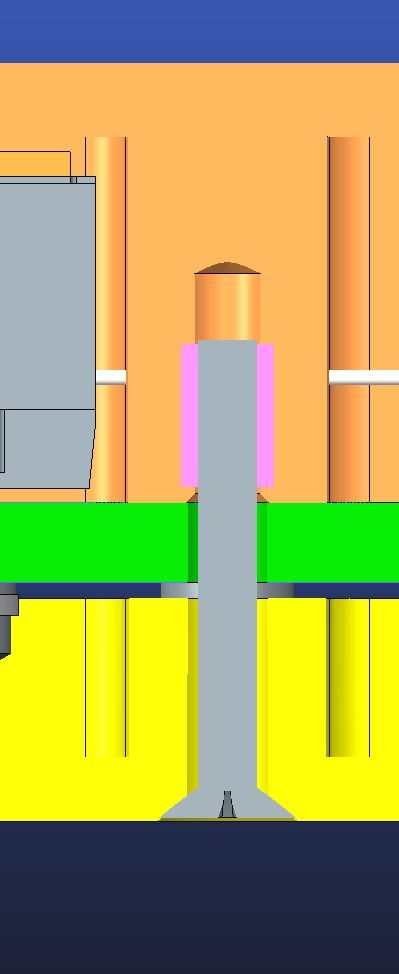

Hi you are correct. Here is the correct view.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi everybody,

in Simulate the screws/bolts idealization works only between TWO parts. If you have more than two parts you cannot use that kind of idealization.

If your focus is analize what happen exactly "under the washers" and/or exactly at the interface around the hole between plates green and brown (e.g.: you are interested to see the shear force the friction exchanges) then you must put contacts interfaces. Then you can use a pre-loded point-point spring or a point-point beam with heat load (there is also a third way, namely by using the preload feature over a solid screw...but this feature was introduced from Creo 3). In this manner you can get the best quality results against much more computing time because it's a non-linear anlysis.

If you don't need all of this, I reccomend you to use bonded interfaces.

Remember that under screw's head and nut, that in the feature are indicated with the parameter "Fastner Head and Nut Diameter", you need to have "material" to create the cone of compressed material beetwen plates (see attached image). So, in case of linear analysis, I suggest you to reove any washers.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you very much graulini.