Community Tip - You can change your system assigned username to something more personal in your community settings. X

- Community

- Creo (Previous to May 2018)

- Creo Modeling Questions

- Re: Is there a way to fill the hole?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Is there a way to fill the hole?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is there a way to fill the hole?

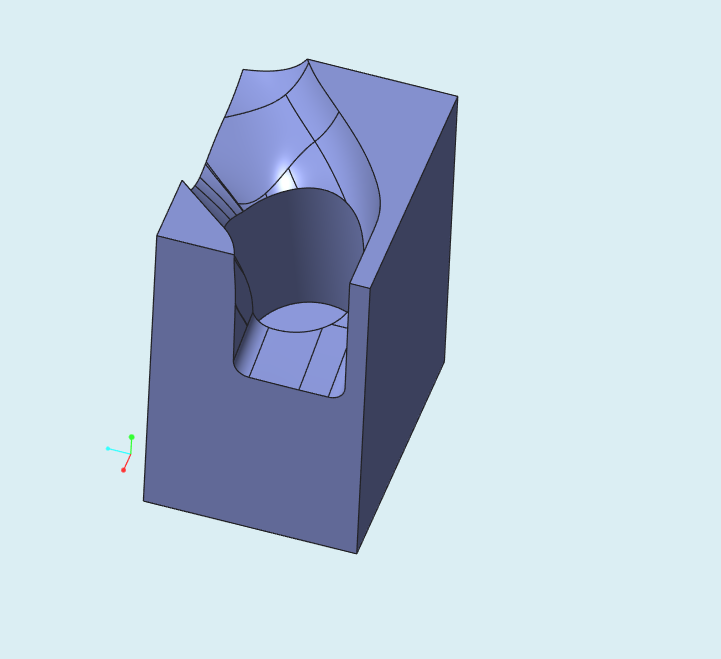

Hi, In creo is there a way to fill the hole? see the attachment.Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

great work....wondering if duncan can show how he did it in NX

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I tried, but for me I think the problem is getting good data from this Step file. If I use high accuracy model as a template, the incoming model has bunch of mangled surfaces.

Data comes as a solid in if I use a low accuracy model template, but it seems that soon after things go wrong because boundary blends don't work as the selected edges do not form valid loops, and projected curves end up with missing segments or little segments going back on themselves.

And trying to fix the data with the Import Data Doctor gave me a headache. So time to stop and have a weekend vacation away from Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think this is a no-win challenge in Creo. And you are right, the provided model is less than stellar.

The only thing that will work is to rebuilt the entire surface with sections and reference points for either a blend or boundary blend. You can use exisiting surface to characterize the new surface, but in general, I would try to make it independent. In IDD, separate out all the affected surfaces so they can easily be removed for the solidify process. Then determine the best way to rebuild the existing and missing geometry.

Blue... what is this feature?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Model with accuracy ~0.05 mm is simply a trash.

For manufacturing purposes it should be rebuilt from ground up. Moving it from software to software will just let it cause a never ending mess.

Anyway here is quick fix in Rhino.

Manufacturing it using RhinoCAM would do the job, but moving it to Creo and try to solidify it in say accuracy of 0.001? Not a good idea.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

solidworks fill option has also failed.

....

Creo "remove" tool should be made more powerful...

ISDX surface also fails to do the job...

The geometry is very poor...

Curious to know how NX was able to do this...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Guessing!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

nice video...i think G0 is a free connection..so many places it is not tangent...right?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

actually,the original geometry has something defects.Or it can be G1 connection.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Very impressive! Yes, Creo should be able to do this with a simple coundary blend. -Should-, being the operative term here.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

As I know, the similar CAD system such as CATIA UG/NX Solidworks have the fill capability.But Creo...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

done in solidworks 2012

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I can't open native Solidworks file, but i performed a reflection analysis on STEP coming from Solidworks. It's ok. Just a zone with no tangency but i think it could coming from STEP conversion. It seems that solidworks and nx manage surfaces with no respect of patches of near surfaces. And that's good.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This should be highly embarrassing to PTC! ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

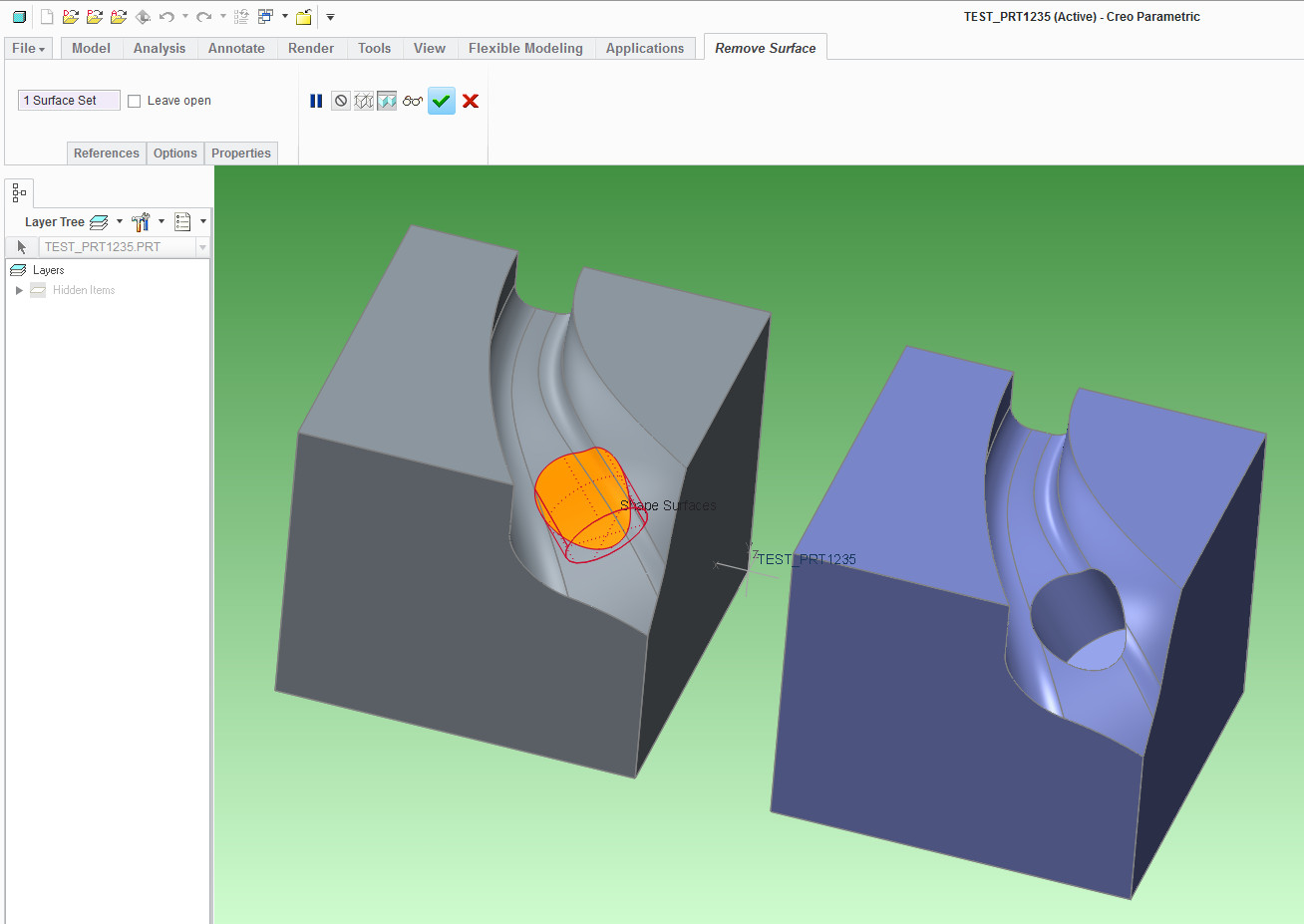

Yes, it seems Creo is pretty weak with dealing with bad data. I've made a pretend model that mimics what the OP was trying to do.

Funny thing is, the software is quite capable of dealing with such holes if you are working with native data.

You can use flexible modeling "remove" feature to fill in holes like these very easily.

Another way is to copy and paste the surfaces and use the "fill holes" option.

Here's where things go bad: After exporting the model to STEP format and then bringing the data back into a fresh session, the IDD reports that model has bad vertices!

Now the copy surface and fill holes option no longer works.

But, as shown in the image above, the flexible modeling "remove" method still works.

So maybe there's hope but only if your geometry doesn't have big errors (and how often does that happen ? ![]() )

)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

we so much want..that CREO should be the best software..but i think...PTC does not share the same vision?![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think PTC should give this challenge to their R&D quys logging exactly how long it takes them to figure this out.

And their performance should be part of rating their their next review.

And if it requires the advanced surface extension, knowing it can do an adequate job in SolidWorks... maybe the advanced module should be included with core Creo.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

the ISDX surface option does not work with non-tangent edges![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Does PTC cover up their shortage?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

only PTC can answer this i guess..![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

+1

Not that I believe it has gonna have any impact anytime soon, but can anyone be bothered to post this in the ideas section?

I'm sure there is more than just a handfull of us who would like to tell PTC what is the real meaning of "AnyData Adoption".

http://creo.ptc.com/2010/10/27/any-data-adoption/

Let me also bring up the terms "Unite Technology", and "Flexible Modeling". Though, these are the bells and whistles we are not gonna be able to use on some (or maybe most) occasions, just because of the way Creo treats the input data.

I guess you realize it doesn't have to be only STEP or IGES data coming in. It can be data from say Catia directly, which Creo Parametric treats in alot worse manner than STEP data during the import, meaning it introduces alot more bad geom, gaps, etc.

http://creo.ptc.com/2014/07/28/ptc-creo-fmx-and-unite-technology-better-together/

STEP, IGES or any universal data format type is just a middle man in the process of data transfer. It's an unnecesarry copy of the geometry, that serves only as a link between all of the CAD/CAM systems out there. For PTC to eliminate this link out of the process they will have to make sure the software can easily deal with data such as posted by the OP (Blue).

Regards,

~J

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

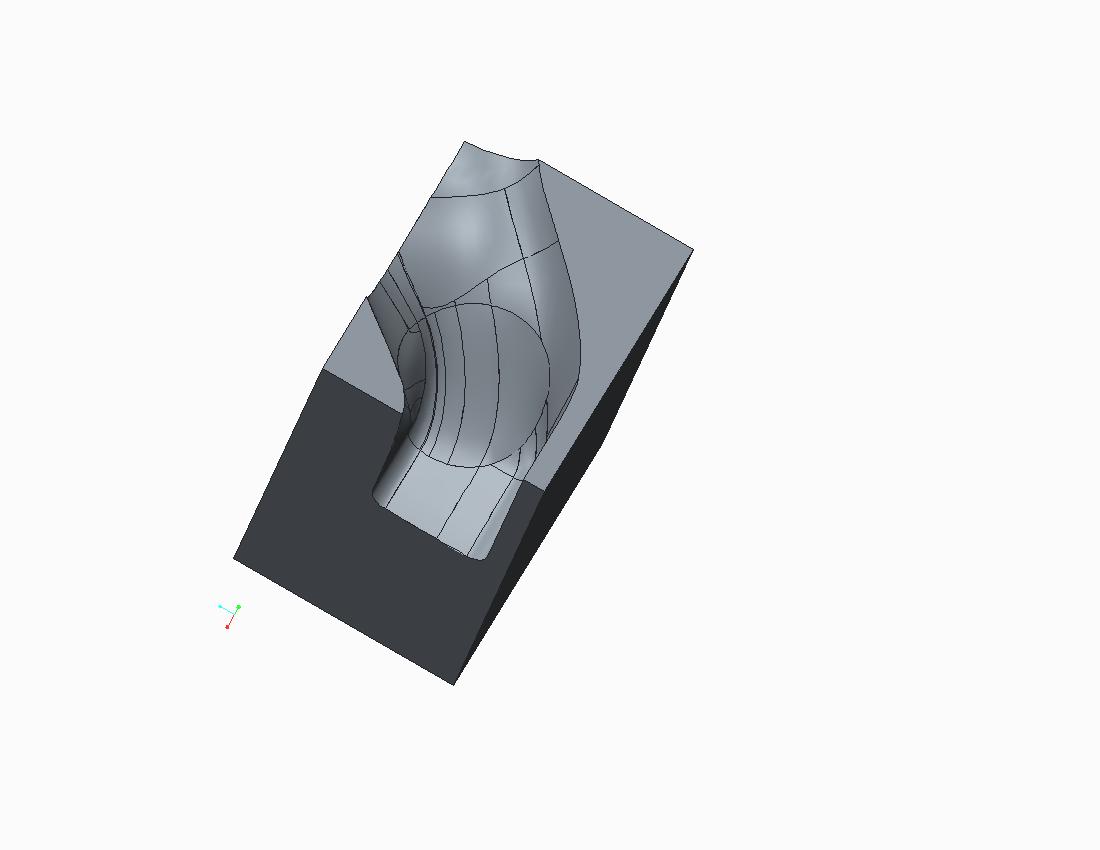

ok this one is in creo 2.0..step file attched as i hace student edition

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Rohit, this is easier to do, yes, but nowhere near industrial-design-guy-proof...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

could you please explain me further?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

There's no complete tangency on Rohit's step. No hidden visualization with white edges shows no tangency edges. I improved a little with IDD, but that tool can't force tangency anywhere. Anyway to repair a 3D file is good. For manufacturing no.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

NICE ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have no excellent skills in ISDX module, but i reach a complete filling of entire surface with tangency continuity. I rebuild surfaces. Expecially near the hole, geometry was very poor. IDD isn't a perfect solution. I think that for guys of reverse enginering filling this hole is a joke. Sure it's not a 2 click work as in other software. I attach Creo2 and STEP file. There are little distorsions on my work, but i'm not a specialist.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Solidworks and NX both use Parasolid Kernel, maybe this is a limitation of Granite?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't think so,In advanced surface,Creo is weak compared with NX.Creo just provide IDD TOOL to fix input data(igs/step).It's a limited capabilities tool. From Proe to Creo ,do you see the advanced surface be enhanced?![]()