Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo (Previous to May 2018)

- Creo Modeling Questions

- Re: Is there a way to fill the hole?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Is there a way to fill the hole?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Is there a way to fill the hole?

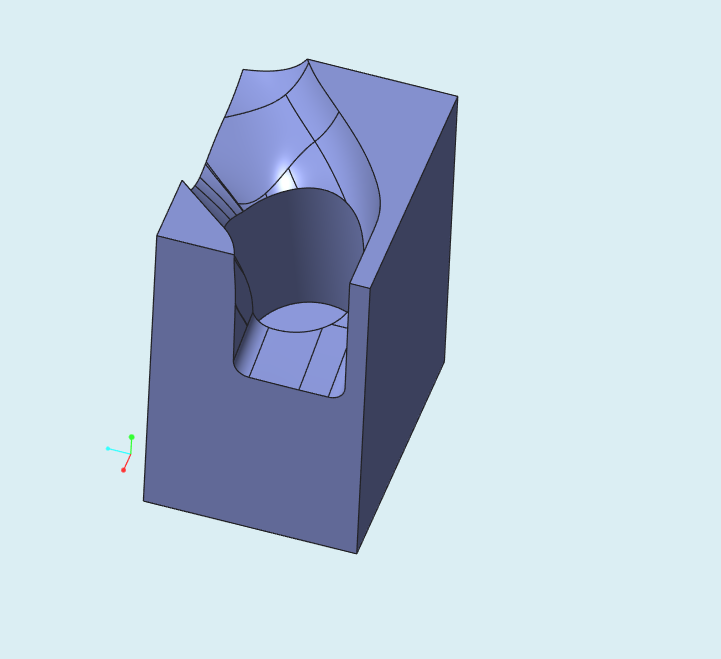

Hi, In creo is there a way to fill the hole? see the attachment.Thanks!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I understand what you are getting at. People should not use Creo and should use NX or Solidworks because those programs are better in every way.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I see this thread as a way to show that some competitors of PTC are doing better productivity wise in this particular example.

I certainly don't doubt Creo more than I did before reading this thread.

One thing that I always tell my colleagues is if you only know one CAD software then you will become a toast one day.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Seeing how other software functions is interesting.

This case is a test of the ability of software to handle an unusual case where the geometry has been purposely damaged, but the user doesn't have enough information to recreate the part independently. A few people might have this happen as part of their work, but I would not want an expensive software development effort to fix a problem few people have when there are more universal enhancements to be made.**

If someone brought a metal mold with this complex curvy channel into a machine shop and then bored a big hole in the middle, what would the expectation be of repairing it?

This question boils down to - can software make a surface the user could not create on their own? I think it is interesting that other programs may be able to handle this problem, but it's not a problem Creo Parametric was designed to fix.

I note, for example, that Creo Parametric doesn't handle draped fabric very well and it doesn't have a Compositor for video or a non-linear video editor. All of these come free with Blender, but it is unlikely for PTC to build all these features into Creo Parametric.

It's good to know that using NX or Solidworks is an alternative when managing damaged surfaces. It's not good to complain as if there is no cost to developing a means to resolve this or that it is a software sales driver. Maybe there's a lot of demand for repairing overly-patched surfaces, but I think it is as much as there is repairing brutally damaged molds.

**Yet again, recent post about needing to control part color. First raised before Rev 14, and still not dealt with in a direct manner. The number of items that get different paint colors for different part numbers has got to be more than the number of defective geometry imports that need to be fixed in 2 steps or less, even if the desparation felt by users in the two groups isn't.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This is certainly not the 1st case of having to create a patch where the challenge was greater than it should have been. This is not something that is relevant to only repairs. There is a host of issues with trying to cleanly patch up a corner for cosmetic reasons. I can accept that an ISDX extension is required for high level curvature control, but to simply create a patch for 3 edges with tangency, that should be a breeze by now.

Remember this "little" challenge?

...or this little discussion?

PTC has enhanced the freeform feature for Creo 3.0 that may be a solution, but for now, boundary blends just fall way short and things like n-sided patches are the old Pro|E xtop interface and are hidden by default.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes, I recall this one - it's a smoothed blob shape, one of an infinite number of similar blobs caused by varying degrees of curvature and transition types.

The target market for curvature controlled surfaces seems to be served by ISDX, as shown here http://www.youtube.com/watch?v=Zp1C1Y9Mfko

It looks like ISDX does a great job and offers much more control to the user.

Maybe such blends should be included as part of the low cost license, but that's up to PTC to decide to offer it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

This isn't aimed at anyone specific, I am just posting to the bottom of the thread.

In my opinion, none of the above pictures are (still) 100% correct. So people that are commenting that other tools are superior, in THIS CASE, I don't see it. Doing something wrong is similar to not doing it at all for me.

Now if people have similar issues with other models and they are easier to fix in other tools, that's great!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

CATIA too does it successfully...

Step geometry comes in much better

- « Previous

- Next »