Community Tip - Want the oppurtunity to discuss enhancements to PTC products? Join a working group! X

- Community

- Creo+ and Creo Parametric

- Manufacturing (CAM)

- Re: Basics - use of calculations, equations

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Basics - use of calculations, equations

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Basics - use of calculations, equations

Hi

In a turning operation, I would like to use a variable CUT_FEED which is currently 10. This value should depend on the workpiece diameter:

- when ØA then CUT_FEED B

- when ØA/2 then CUT_FEED B*2

Cheers

Bob

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hi,

inside parameters open edit machining parameters->select cut_feed and you ave "d=" it is symbol for equation-open it and write:

work_dia=workpiece_dia:4

if work_dia>=10

cut_feed=15

else

cut_feed=5

endif

where work_dia is a parameter to workpieces diameter.

br,

ionut

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Ionut

I understand the logic around but I got some errors with 'workpiece diameter' parameter. The workpiece diameter should vary with STEP_DEPTH.

work_dia=workpiece_dia:4

error Invalid symbol 'workpiece_dia:4' found.

if work_dia>=10

error Invalid symbol 'work_dia' found.

cut_feed=15

else

cut_feed=5

endif

Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

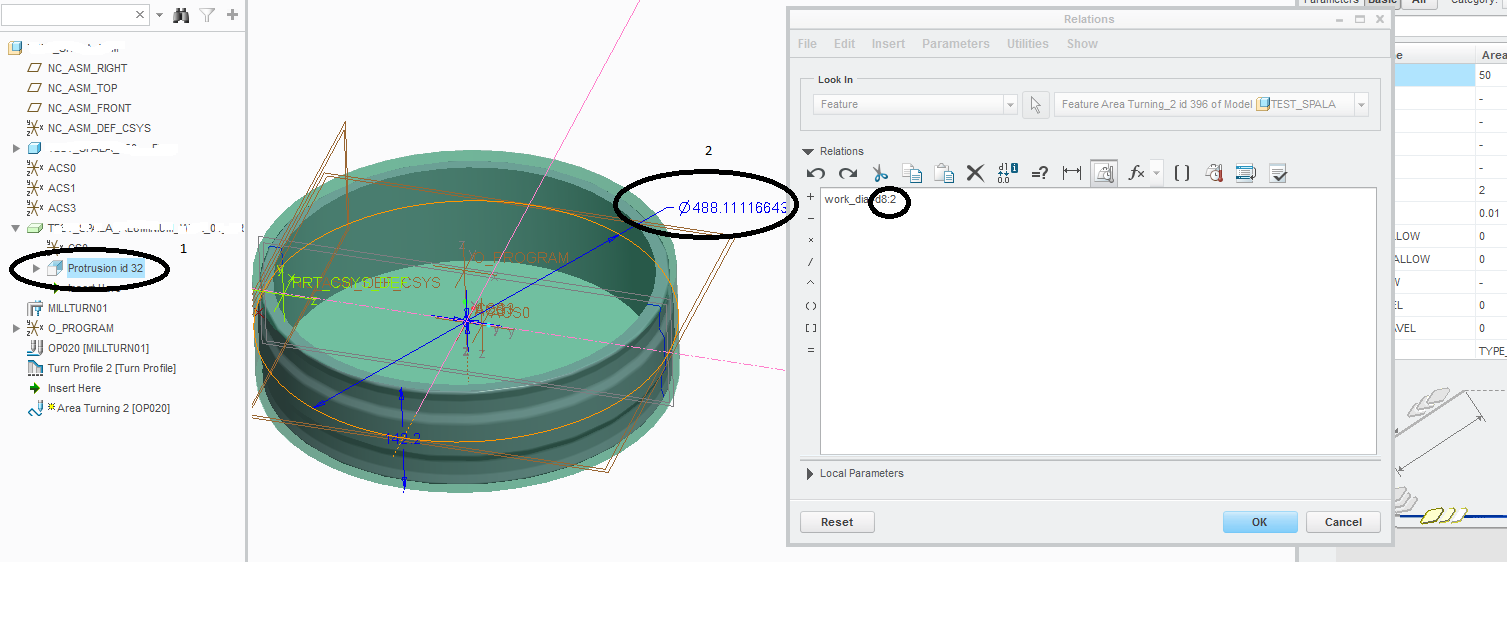

when you write work_dia = "you have to select the revolve, extrude , or the feature from workpiece, then it will appear the dimension and you select that dimension" - in my case the was workpiece_dia:4 but usually it will be d3:2 or d8:2 someting like that.

Br

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi

I got there but it doesn't work once your update the values. Not sure whether a bug:

1) spindle_speed 100

2) cut_speed = spindle_speed * 0.5 /// but it stays on 20 even once parameter applied

- tried several but even time of operation is staying same unless I change 20 to something else

Another issue is with the spindle_speed [rpm?]:

1) I entered spindle_speed = (50 [m/s] * 60 [s]) / work_dia [m] * PI /// calculated ok

2) now I entered cut_feed = spindle_speed * 0.05 [mm] /// calculated ok

3) I want change spindle_speed but it appears equation used in cut_feed above!

Are these bugs or is it just so primitive?

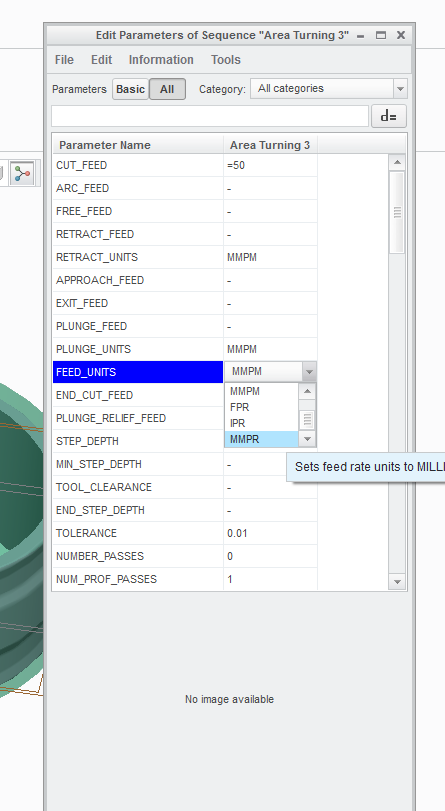

What kind of units does it accept? Is there any *.pdf that might help with these basics?

Thank you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

hi,

It should work, i have tested and the result is good

you can setup units from standard drop down list, see attached picture.

br

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Ionut,

Bob wants to use relations ! Your procedure is not using them...

MH

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The way you know a manufacturing parameter is defined by a relation is if in the listing the value is preceded by an "=" sign. You see the actual relations only if you select the parameter in question, or by accessing the Tools->Relations menu item. It's kind of odd, that way.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Martin

If you have some idea how to continue.. Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks, that all worked.

But how to adjust the spindle speed according diameter? I am trying to change speed_control but when looking later on the g-code feed rate F does not change.

I thought 2640 would represent cutting speed 44m/s x 60s

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

try following:

- open manufacturing assembly

- Tools > Relations

- on Assembly level define a relation ... SPINDLE_SPEED:FID_featureID=wpdimension:sessionID

where

featureID is ID of specific NC sequence

sessionID is ID of workpiece - regenerate manufacturing assembly

Unfortunately the relation does not lock SPINDLE_SPEED value, you can modify it in Edit Parameters dialog box. New value will be changed back during following regeneration.

MH

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Martin

In my case, I guess under the NC sequence is 2857, then under workpiece 2744.

Tried some combinations, did not lead anywhere.

Where am I doing mistake? Thank you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

1.]

SPINDLE_SPEED:FID_2857 notation is CORRECT

If you enter relation SPINDLE_SPEED:FID_2857=1234 Creo accepts it and set the SPINDLE_SPEED value for feature ID 2857.

2.]

wp_d:2744 is nonsense

wp_d is local parameter which does not have any relation to feature ID 2744.

3.]

wp_d=d8:14

d8 ... is workpiece diameter dimension, session ID of workpiece is 14

4.]

It is not necessary to use wp_d parameter.

Use following relation:

SPINDLE_SPEED:FID_2857=d8:14

5.]

How to get session ID of workpiece:

> open manufacturing assembly

> Tools > Relations

> click Show > Session ID > Part and select workpiece in graphics window -OR- in model tree

> read message in Message Window ... Model XXX.PRT has Session Id nnn.

6.]

Note: In workpiece you can rename d8 dimension to some meaningful name, eg. wp_dia.

Relation changes to:

SPINDLE_SPEED:FID_2857=wp_dia:14

7.]

Note: Session ID is not fixed number. It is assigned dynamically by Creo.

MH

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've been doing a LOT of calculations in assemblies lately, using relations to drive geometry in sub-components, etc. There are some observations about the session ID that I've noticed:

(1) Parts in the session (xxxx.prt.nn) always have even numbered session IDs (0, 2, 4, 6,...) which seem to be issued in the order that the parts are loaded into memory. Assemblies (yyyy.asm.mm) have odd IDs (1, 3, 5, ...). A good thing to know for catching typos.

(2) If a part in your assembly is an instance of a family table part, and you want to affect that part with a relation, you might have to apply your calculations to the generic model, not the instance. This means you have to get its session ID using its name, not by picking anything on the screen. Took me a bit of time to figure this one out - I'd set a parameter in the instance, but it would revert back if I regenerated, etc.

Relations can do a lot of cool stuff, you just have to get used to the fact that some of the information gathering necessary to use them is kind of clunky.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Dear Martine

I have been able to follow your and currently use correct feature and session IDs and understand the points 1-7. Thanks.

- when trying applying this in Area Turning Parameters and then SPINDLE_SPEED . . . SPINDLE_SPEED:FID_2896=(1000*60)/(d8:6*pi) [speed per minute divided by workpiece perimeter] - when checking g-code there is used used one speed, so not working

- when using according your comment earlier

- open manufacturing assembly

- Tools > Relations

- on Assembly level define a relation ...

SPINDLE_SPEED:FID_2896=(1000*60)/(d8:6*pi) - it is accepted again but does not work neither

I need a break for a couple of days. Thanks.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

Info:

We tested relations in combination with NC Sequence. We did not test Operation (as you did) !

Question:

You have to regenerate assembly to update NC sequence parameter !

MH

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can put simple relations in your site file, if you want them to carry over to all sequences. If you then put this site file in your template start manufacturing model it would be there for all future programs.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Bill, I am trying to make it work first. Later, I can play with more advanced further functions.

Would you know how to raise or lower the cutting tool in turning?.. Thanks