Community Tip - If community subscription notifications are filling up your inbox you can set up a daily digest and get all your notifications in a single email. X

- Community

- Creo+ and Creo Parametric

- Manufacturing (CAM)

- Re: Containing toolpath in Roughing

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Containing toolpath in Roughing

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Containing toolpath in Roughing

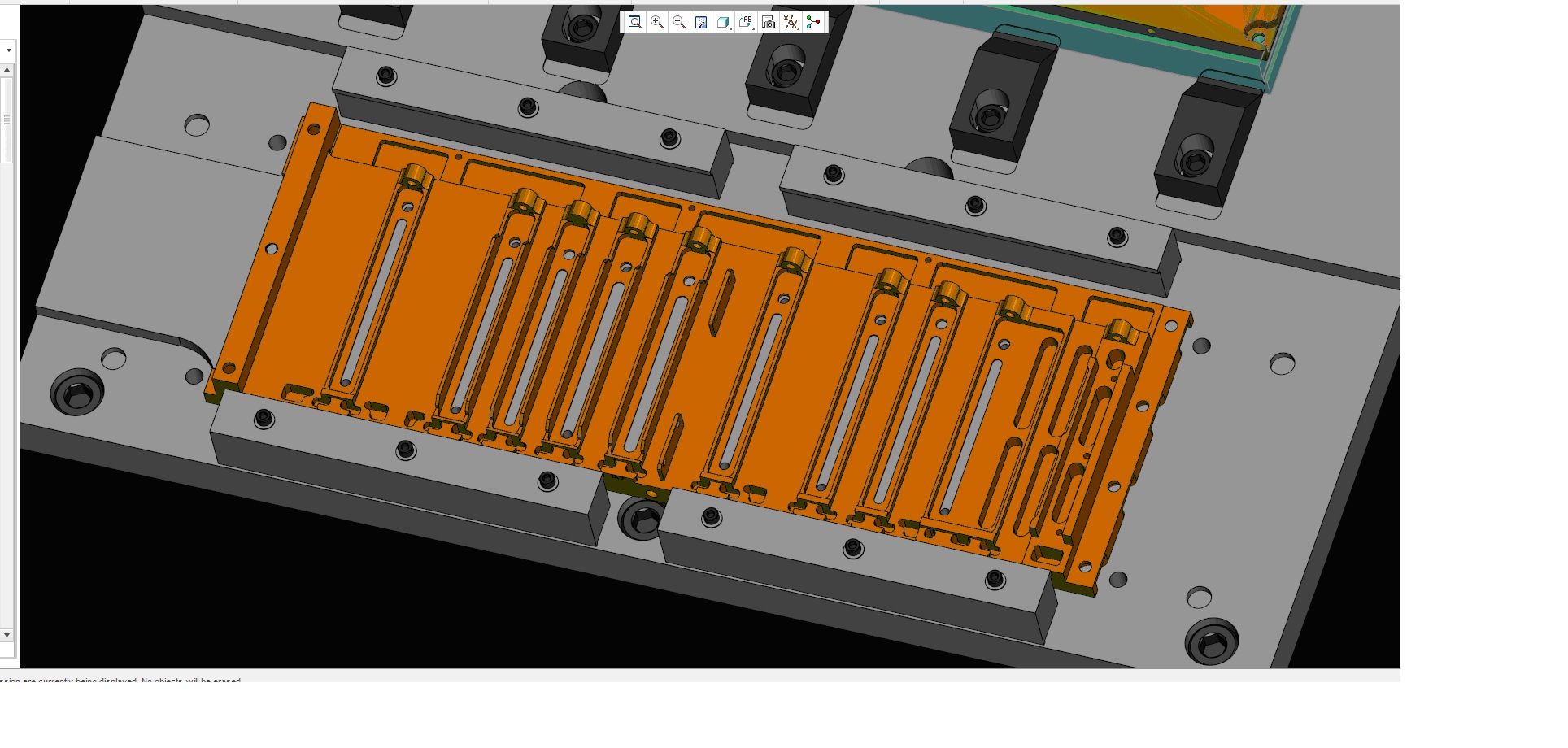

When trying to create a roughing sequence the toolpath goes outside of the mill window. I need to control this because I have side clamps on my part. I have the mill window set to keep tool inside of the window. When I use the same mill window and use Volume Rough it works fine. Has anyone ever had a problem with this?

I am using CREO 2.0 M050

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

When it comes to roughing cycles windows have always been more of a suggestion than a hard boundary. If I had to do it I would problably model in your clamps the tool should go around them.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Jason,

I was going to suggest what Nick said. If you are just using toe clamps you can use the ones in the tooling library so you don't have to model them. they already exist. If you assemble them in the fixture they should not get cut.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I do have my clamps modeled into my assembly.

The only problem that I may have is that when I build my assembly I build it using the Assemble button. I don't go thru the Fixture module. I do this because it takes more clicks when using the fixture module. Is there a way to build an assembly and then classify parts as fixtures?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

jason,

there is a classify function but I have never used it so I am not sure if you calsiify the clamps as fixture parts..

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Jason

This is from PTC Document CS65743

In the roughing command the mill widow is treated as past it uses the surfaces to machine to the mill window is only used to drive the toolpath

The best way is to model the clamps and then bring them into your assembly by the fixture method if you bring your models in as assembly and classify it should recognize the models and not machine the clamps. I need to do some testing to make sure this is correct I tend to bring them in using the fixture method for this very reason.