Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- Manufacturing (CAM)

- Re: How to have mill path follow outside in, inste...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How to have mill path follow outside in, instead of inside out.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How to have mill path follow outside in, instead of inside out.

I have always struggled with Creo when it comes to getting good millpaths. No matter what I try, it always seems like Creo defaults to pushing the cutter directly into the middle of the part (material fully surrounding the cutter) instead of slowly milling its way into the part from the outside in.

I have dealt with this issue for many years now, and decided it's time to make a post here asking for help. As you can see in the video, it would be ideal to mill the outside first, allowing 2/3rds of the cutter in the material until it mills completely to the center.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

Can you send the sequence parameters?

try SCAN_TYPE to CONSTANT_LOAD

The best solution is to use the HIGH SPEED MILLING option

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I tried CONSTANT_LOAD and every other SCAN_TYPE with the same results. This has been an ongoing issue for a very long time now where we fumble our way through Creo toggling every option on or off, then adjusting the mill window just a hair until finally by absolute luck, we get somewhat of a workable toolpath, albeit still with issues that we cannot control.

As far as high-speed machining goes, we do not have that extension. But I am curious why we would need extensions designed for mold making and 5 axis machining just to get a usable toolpath for the ultra-simple machining that we do here?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I don't know what type of toolpath sequence you're using, but I've always been able to get exactly what I want with Classic NC Steps -> Custom Trajectory. It's not an automated method of defining toolpaths, but I prefer the control it affords me.

I find that the "easier" sequence types, volume milling and the like, don't do exactly what I'm looking for.

Unfortunately, to use this type of path definition, I needed to define a config.pro option:

enable_classic_nc_steps yeswhich is a hidden option. Maybe someday it will go away, but it hasn't yet.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

What type of sequence are you using? In Volume Rough, you could try "Cut Direction - Reverse" if you have not already done that. For the most part, I don't see any issues with sending this type of cutter to the middle of the material and letting it work itself to the outside, but I do know of a few paths on things we do that we use the reverse cut direction.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am using Volume Rough. Thanks for the "Cut Direction - Reverse" suggestion, as I was not aware of that parameter, and it does get the toolpath much closer to what I would consider ideal. The issue with sending a face mill to the center of the part is chatter. That ensures the full diameter is completely surrounded by material on all sides, when it is much better to use 2/3rds of the cutter to remove material for less chatter.

I will play with this "Cut Direction - Reverse" more, but it does look promising!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

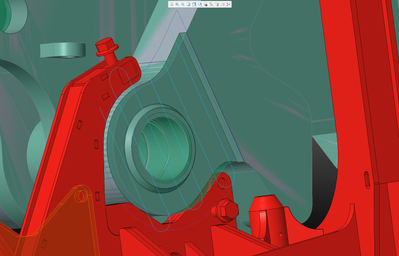

An Ideal toolpath (Until it got down to the chamfer area) would be something like this which uses 2/3rds of the cutter per pass, but I would like to get Creo to do this without me having to manually sketch it out and then using a trajectory pass. I would like the software to work for me.