Community Tip - You can subscribe to a forum, label or individual post and receive email notifications when someone posts a new topic or reply. Learn more! X

- Community

- PTC Education

- PTC Education Forum

- Re: Any one got a good 3D printer?

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Any one got a good 3D printer?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Any one got a good 3D printer?

Hi Tim/Every one!

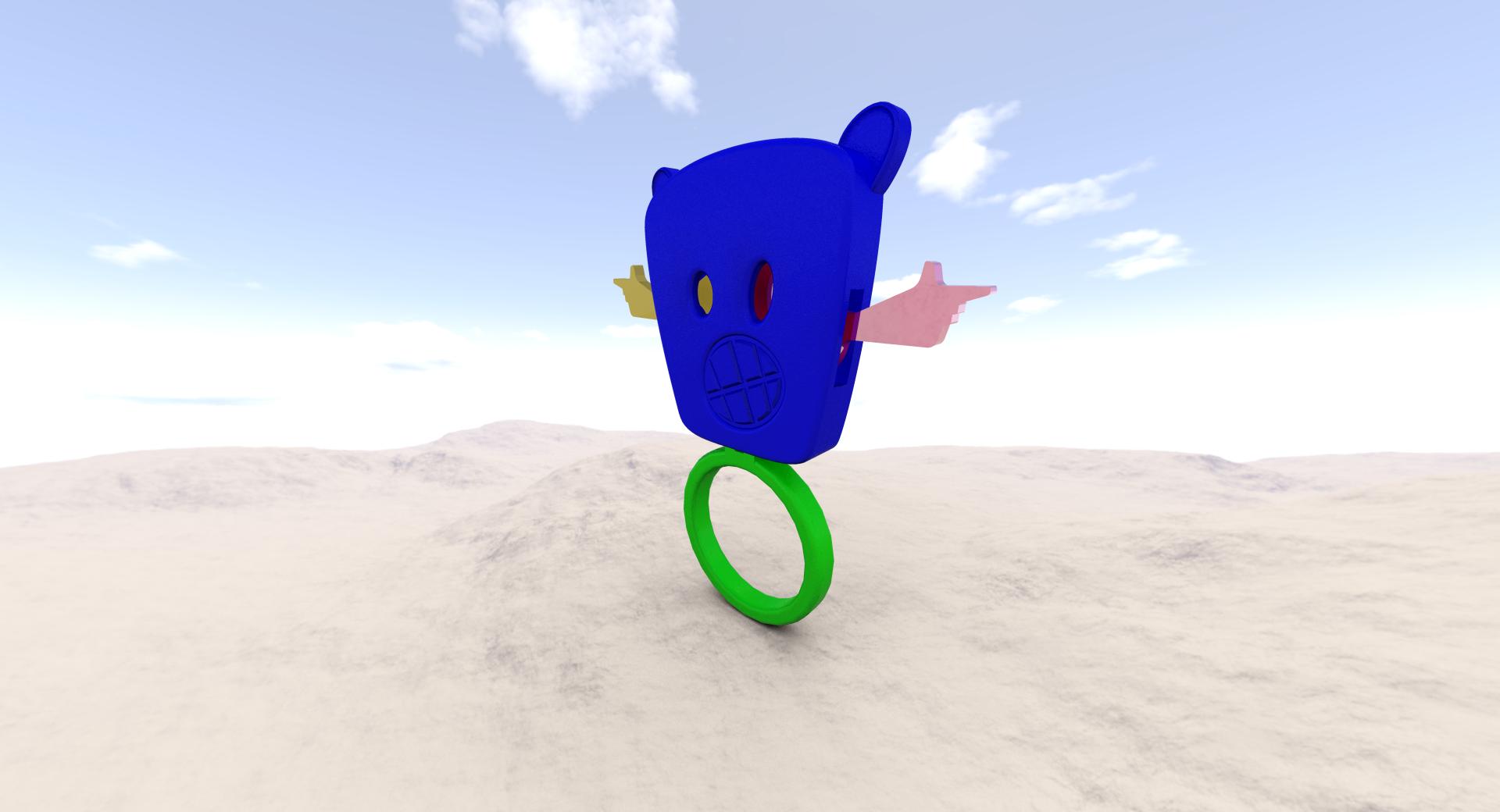

As you know we've got a basic printer as school and it works OK but- now that we've got going with Creo I'm experimenting with intefacing components to make "real world" products.

Its a ring and when you wiggle your fingers the arms move!

Except our 3D printer is struggling to print the arms.

I've uploaded the Creo file (any suggestions on getting the meech right?) and an stl version if anyone owoud like to have a go at tthe product.

Let me know how you get on and hoow the parts interfaced.

Best regards

Peter

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

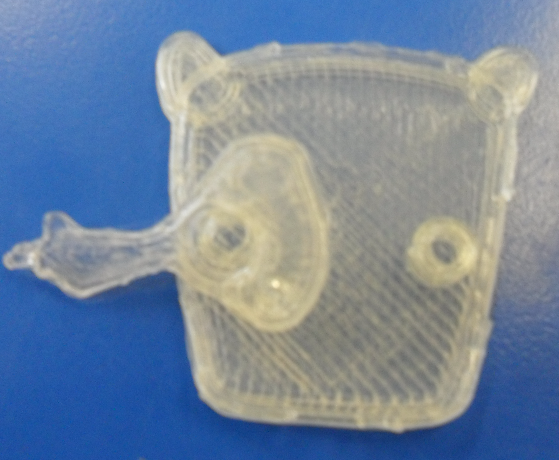

Hi Peter

printed your design on an Up Plus 2

no problems and worked fine. printed it face down to get the insides clean for the mechanism, otherwise loads of support removal and cleaning up would be required. as it is a quick rub with wetand dry would make it shine.

Jeremy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Peter,

I love the idea of kinematic jewellery! It's great to see designs being manufactured.

You don't specify the problem with the arms. Are they too thin, could you beef them up a bit?

If you are getting separation between layers, it helps if you get the bed/chamber up to operating termperature before you start the build. Avoid cold rooms and anywhere there might be cold air/drafts.

The STL export from PTC Creo gives control over the mesh size. The attached instructions explain how to get a fine mesh.

.

It might be possible to get your models made on a professional 3D printer, I'll email someone I know and copy you in.

I'm looking at how you assembled the parts in Creo and think there miight be a better way. I'll check it out and, if it works, I'll upload the result here.

Keep up the great work!

Tim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Cheers Tim,

Thanks for the pdfs.

I'm having problems controlinng the "squash" effect and the inteference sizes. The arm thickness is alright & we've got no kids in today so theres no cold air being swirled around!

Have a good weekend

Peter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Peter,

Attached is the assembly with different constraints.

- On the link(ring) I replaced your planar connections with a slider connection and limited the vertical movement to 3.75 mm.

- I replaced the pin connections on the arms with cylinder to allow them to float along the axis. This was need for the slot connections below to work.

- I created a datum point at the base of the circular bosses in the arms.

- Sketches were created in the link(ring) along the centreline of the slots.

- Slot connections were created between the datum points in the arms and the sketched lines in the link.

The model should move kinematically using the drag tool.

Let me know what you think.

Cheers

Tim

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Tim,

I'll have a good look at the file.

Got a good print out this afternoon.

Pics below.

And an attched avi of the physical assembly.

Have a good weekend

Peter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Brilliant, well done! ![]()

Which 3D printer are you doing this on?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We've got a basic Bits from Bytes Rapman 3.1 that came as a kit. We've not really had much time or resources to "improve" it. Its taken 3 years to upgrade ProDesktop and get a replacement laptop. Were going to try a heated enclosure and finance upgrading the driver hardware to take better hardware. What I'd really like to finance is a replicator type.

Peter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well done getting the Rapman working, I gather they need constant tinkering to get them to work properly.

By coincidence I am setting up a brand new Up! Mini this weekend for a course this week. I decided to try your ring components but having trouble. The parts curl up and come away from the table part way through the build. The arms came out fine and can be seen at the right of the photo below. The bed isn't getting hot enough so will have to contact the supplier on Monday. ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

That's a bit of a buzz seeing someone else printing my stuff. Are you using ABS? Can you set the bed temp higher? Try 5degree increments. Personally I prefer to use PLA as it seems to vary less than ABS. For what it is worth the arms didn't print that well on our machine! I always try to print without a raft too. All the tinkering does have some benefits.

Good luck

Peter

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

ABS came with the machine so no PLA available.

The bed temperature displayed in the software never changes from 60.4 degrees C even at switch on! The bed heats up but there's no way of knowing how hot it is. I left it heating for half an hour and it's just possible to touch so estimate 60 degrees is about right.The user manual suggests over 100 degrees is needed.

Thanks for your suggestions, I just found a setting in Maintenance to pre-heat for an hour so will try that next with no raft. Will keep you posted.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Update - I ran out of time to get this sorted before the summer break.

I'm told the second UP! Mini had the same problem and had to go back to the supplier. The University has let me know the machine has been fixed and returned but haven't been able to go in and test it yet.

Watch this space...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Tim, hope you had a good break. Interested to know how you get on with the UP! Sub 10k 3d printers really are not plug and play yet!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Peter

printed your design on an Up Plus 2

no problems and worked fine. printed it face down to get the insides clean for the mechanism, otherwise loads of support removal and cleaning up would be required. as it is a quick rub with wetand dry would make it shine.

Jeremy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well done Jeremy, this looks great. ![]()

The full size UP! and Makerbot Replicator 2 seem to be the most popular 3D printers in UK schools.