Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Community

- Creo+ and Creo Parametric

- System Administration, Installation, and Licensing topics

- Re: How can I make solid geometry in SheetMetal by...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

How can I make solid geometry in SheetMetal by Creo 2.0?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How can I make solid geometry in SheetMetal by Creo 2.0?

Hello Everyone.

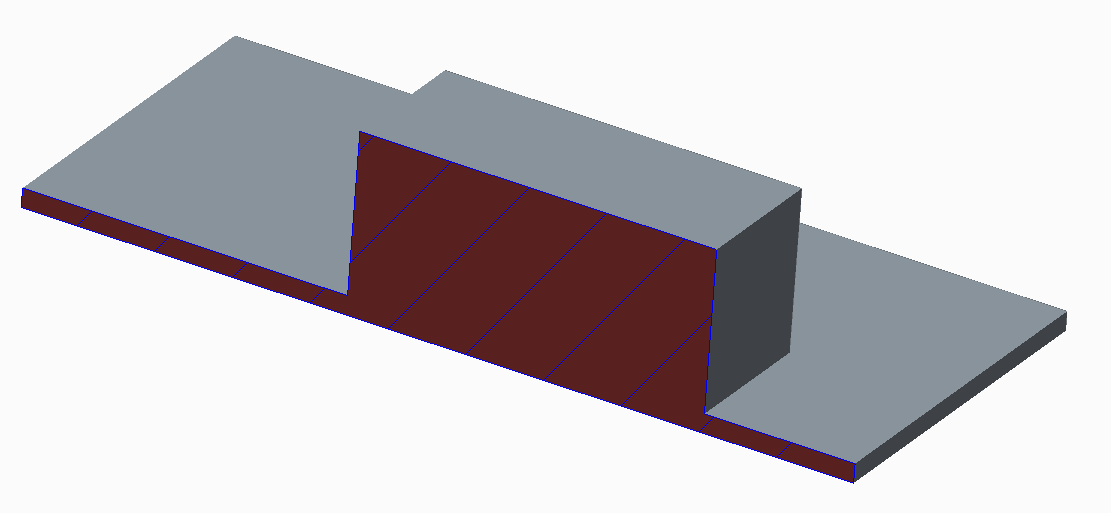

How can I make solid geometry in SheetMetal as below image?

Also I founded hidden config.pro that "allow_smd_solid_features yes" but I don't know what kind of menu is added or changed?

Thank you

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Nice find on the hidden feature! Unfortunately you never know when support for such options will be unsupported.

The only way I have been able to get solids into sheetmetal is to Switch to Part Solid in the Model>Operations tab. That is a drastic step, however, since it is not easily reversed.

The best solution (IMHO) is to create a next level assembly to add the solid to the sheetmetal. this is how I create inseparable assemblies where press-fit fasteners are installed. I tend to do some welding requirements at next level assemblies as well. This gives me good control over what I want on the fabrication drawing.

If you plan on thinning this to the sheet metal thickness later, however, you could look into the form features.

I'll have to look further into the hidden feature you found.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have activated the option and I see nothing different. I wonder if this has to do with inheritance features(?)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I am not sure. I just found out this hidden config.pro

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

My question is how are you planning on manufacturing this in the end? I ask because, historically, Proe / Creo has ben centered around building how you would manufacture it. That's why you cannot make 'solids' in sheetmetal. In real life, sheetmetal is a constant thickness, period. If you want to add a mass to it like you've shown above, you make another part and join it to the sheetmetal by fasteners, welding, adhesives or whatever.

So the best way to do what you're showing would be to make two parts and assemble them together.

I tried the config option as well but didn't see what difference it made either. being a hidden option, it's going to be very hard to find any documentation on it.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

If only we could have pre-perf and expanded metal materials, or even corrugate ![]()

Your logic is sound, Doug. The only thing I miss is "thinning" and realistic extrude limits.

However! You do have weld capabilities within a sheetmetal part, so in essence, you could require different material thicknesses.

Personally, I want to be able to add fasteners, as in PEM features within the part file so the file becomes an "inseparable assembly". From a PDM standpoint, this is highly desirable where one never manage the part below this completed fabrication level.

I know sheetmetal is a basic package and it does quite a bit of nice work. Having control over flat patterns is a real plus for manufacturability optimization.