Community Tip - Did you get called away in the middle of writing a post? Don't worry you can find your unfinished post later in the Drafts section of your profile page. X

- Community

- Creo+ and Creo Parametric

- System Administration, Installation, and Licensing topics

- Re: Lathe boring bar retract

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Lathe boring bar retract

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Lathe boring bar retract

All,

Every time I do an internal area turning sequence with a boring bar on our lathe it never retracts out of the bore to a clearance plane in the Z direction. And we have to customize and rely on our post processor to make sure the boring bar pulls out of the hole completely before it does a tool change. The boring bar will go to where it started in the X direction but not the Z direction.

Does anyone know of a tool parameter, config option, or anything else that we can change to make the boring bar retract in the Z direction?

Anything helps.

Thank you,

Brian

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello Brian,

I think, that there is no parameter or config.pro option to directly solve your problem.

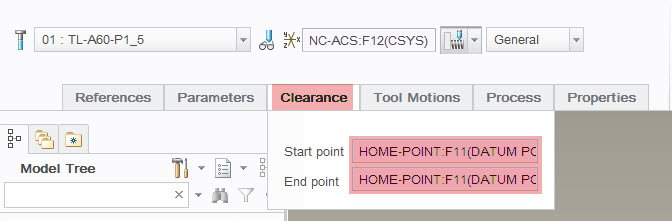

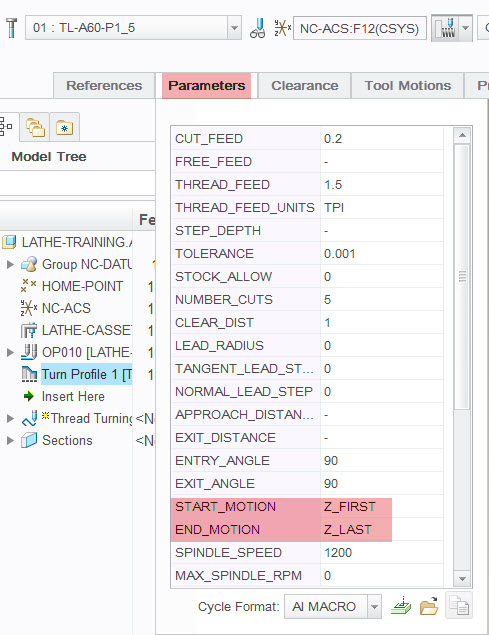

But you can specify the choice End point in Clearance tab. And mfg parameter END_MOTION set to Z_FIRST.

That is probably simpliest solution.

Rostislav

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Rostislav,

I believe you are correct that there is not a config option that would help me out.

I tried the END_MOTION to all of the options and none of them work. Unless one of the other parameters need to be changed.

Setting an end point in the clearance tab does work. It's just very inconvenient that you would have to add a point every single time an internal cutting tool was used. I understand that Area Turning is used for external turning as well and you would not have to send the tool to a starting z position after it's done cutting. But it wouldn't be that big of a deal if did go to the starting z position.

Overall, I'm just asking around to see if anyone has a good way of solving a silly feature PTC has.

Thanks,

Brian

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Like mentioned, it is easiest to populate a start point and end point in the Clearance tab. To make it even easier, set up your MFG start part with Datum Points out in the Z direction at your clearance plane. I set up several arond the OD of a revolved part and also an ID point as well (this one would be useful for the internal bores.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello~~

I think your request only to define parameters then that can be reach you want of Z axis move.

Please take a look below procedure to define your lathe sequence.

I think you need to create a point for "Start" and "End" points reference which columns in Clearance of each sequence. Please follow below procedure.

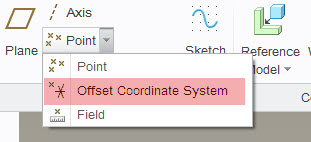

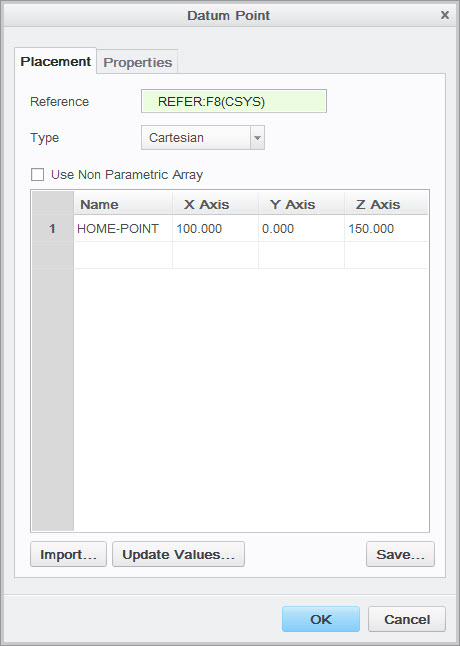

1, Please select point datum “Offset Coordinate System” to create a point (X100, Y0, Z150)

2, “Start point” and “End point” are refer that point in the sequence.

3, Please define “START_MOTION” and “END_MOTION” parameters in your sequence. My opinion is internal tool with “START_MOTION”= Z_LAST and “END_MOTION”= Z_FIRST, external tool with “START_MOTION”= Z_FIRST and “END_MOTION”= Z_LAST.

Have a good day!!

Mark Rao