- Community

- Creo+ and Creo Parametric

- System Administration, Installation, and Licensing topics

- Re: Pro/E Learning Curve

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Pro/E Learning Curve

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Pro/E Learning Curve

There are those out there, not necessarily in the Pro/E realm, that view Pro/Engineer as a software that is difficult to learn with a steep learning curve. I have been using ProEngineer for about 17 years now, and It is my opinion that starting with the Wildfire release; and with each subsequent releases, that Pro/Engineer is becoming more user friendly and easier to learn. I understand that using the software and using the software correctly are two different things, but I feel that the learning curve has lessened with the Wildfire releases. I wanted to start this discussion to see what other users of the software feel about the ease of use and the steepness to the learning curve for Pro/Engineer Wildfire.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Greg. Great topic. I'm looking forward to hearing some responses on this.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Greg,

This is definitely an interesting topic. I am talking to a lot of different customers when writing case studies for/about Pro/ENGINEER and no two stories are the same. Some people have learned Pro/ENGINEER at school or university, others in their job - with or without formal training. Some come from 2D, some have worked with other 3D systems before.

I am attaching the most recent story we did since I think it fits nicely into this context. Coming from 2D and manual drawing, Steve, the teacher had to understand how 3D works first, then found the product easy to learn and he told us that for his young students, learning Pro/ENGINEER is fun.

I guess there are a ton of different scenarios and learning experiences and I look forward to hearing about them here.

Bettina

PS: ... and should anyone of you want to share his/her story in a formal case study like the attached, let me know 😉

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hello

I started using pro/e 3 three years ago, with no previous CAD experience, it was a lot of work, things start falling into place the more you work with it

patience and perseverance are key......don't give up.

I love pro/e now that I halfway understand it.

Rick........my first post in the new forum : )

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Rick schrieb:

I love pro/e now that I halfway understand it.

... like in any relationship. You need to understand someone in order to be able to really love him/her ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The problem is that resellers of other products talk about Pro/Engineer as difficult to learn even though they have never used it. Many have never seen it in action.

In my experience all the software out there can be quickly learned to a point. Very basic modelling and assembly creation is very simple to do in everything from Pro/E to SolidWorks. I've used most of the software currently available.

To properly utilize any tool to it's full potential requires: 1. experience 2. formal training. 3. more experience 4. more formal and online training.

Realistically to properly utilize any tool you need to delve into the depths of everything it can do and all it's functionality. You are not going to learn any software package properly without formal training. Documentation cannot teach technique and the miriad of recommended practices for a particular circumstance.

Many of the people that learn it in college learn very little about what Pro/E can really do. An application that truly has a vast array of functionality takes time to learn. There's no way around it. One can only learn so much on their own and the reality is there is a lot of trial an error involved. Agreed there is still a little trial and error involved after formal training but you at least have a basic foundation of what functionality exists.

I've dealt with many resellers of engineering software that don't even know their own product functionality. Pro/Engineer resellers are no exception to this. These people are sales people and their goal is to convince you their product is better.

I have taken a number of parts and given them to Solidworks, SolidEdge, Inventor resellers and get a response back stating, "Is this a go-nogo deal? We can't draw this."

The trick is to do your own home work and make them show you that it will in deed work for you. Many of the simple programs just don't have the functionality of Pro/Engineer. Maybe you don't need that functionality but if you don't know what your missing, it's a pretty big investment to change midstream and start learning all over again. Not to mention you may have an inventory of poorly drawn parts.

That's my 2 cents.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Very well put!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would say the learning curve is very high, it follows everything else in engineering and science,

it's abstract and complex. That's part of the fun, finding all the crazy(and very serious) things it will do.

Rick

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

In my opinion the learning curve varies depending on what you are trying to do. If you are creating extrudes, cuts, revolves, rounds and what not it is very straight forward and easy.

If you start getting into ribs and drafts that is more complex because you start having to think about order of creation and how different surfaces meet and alignment.

Then, when you are getting into sweeps you add more complexity

Surface blends are where it really starts getting difficult. You have to figure out how to create all the sketches and supporting geometry in such a way that Pro/E can create the new surface with smooth transisitions. I have been using Pro/E for 6 years and have not spent enough time creating surface geometry to make reliable parts. I cannot seem to make the geometry without S shapes and V shapes where two surfaces meet.

PTC has made great steps forward in useability, and I am looking forward to more with WF6. But, they need to figure out how to make geometry work more reliably. No matter what order the history is you should be able to create using what is there. You should never have to go back and recreate a different way and see if the new feature will work now.

I think that is where most of the usability issues come from. Not from how many clicks it takes to do something, but how much time you have to spend to create the geometry the way Pro/E wants it. You should be able to create it the way you want it the first time and Pro/E should be powerful enough to handle it.

Here we have people using Pro/E, some using SolidWorks and others using CoCreate. They are all supposed to move to Pro/E. I get different excusses from the SW people then I do from the CC people. The SW people talk about clicks, infrequent use and remembering, being able to design the part instead of fighting the software, and other stuff like that. The CC people talk about not being able to quickly create ideas, having to fight with the history instead of just cutting off what you don't like, a different mindset in the design technique and so on.

So to wrap up.

I think that Pro/E is a great tool and is loaded with functionality. It is extremely easy to use to do basic modeling tasks, but as you get in deeper the learning curve goes up exponentially. This learning curve is not because the functions are harder to understand, but because it is harder to get Pro/E to preform the way you want it to.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you for your input. This thread is becoming very interesting.

-Greg

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would argue that the "difficulty in learning the software" is directly proportionate to the available functionality of the software....of course the converse would be true as well.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Don't get me wrong. I think more functionality can add difficulty. But, so can not enough functionality. I have to hold that the root cause is how the geometry created is handled by the CAD system. If you have to do a lot of work to set the part up perfect to get the geometry you want that makes it harder to use. If you can do whatever you want and it just works it is easy no matter how many functions it has.

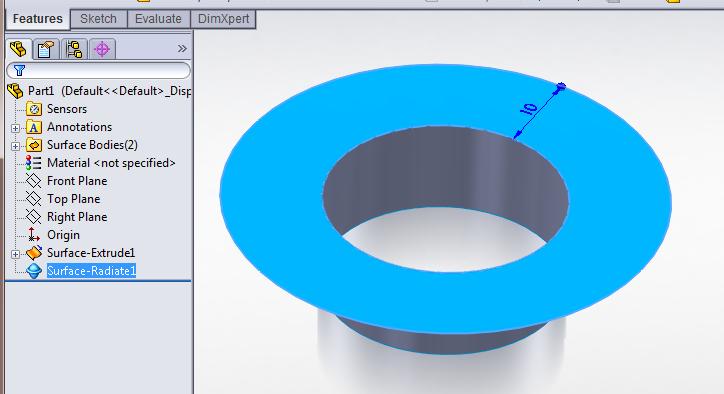

Here is an example. I am not trying to say any CAD package is better then another. This thread is only about Pro/E useability. But, this function came to mind when I was thinking about what could PTC add that would make the software easier to use, but add more functionality.

In SolidWorks surfacing there is a radiate function. It lets you pick an edge and a plane and radiate a surface out a set distance.

If PTC added this it would make Pro/E more complex but would not raise the learning curve as long as Pro/E could work properly with the geometry and you did not have to continually tweak it to get it to work.

So, I am going to hold to my original statement that it is all based on how hard it is to get the geometry you want while staying within what the Tool can handle.

Here is an example picture of radiate if you are unfamiliar:

I do understand that the more functionality there is the more you have to remember to use.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Paul,

You said,

So, I am going to hold to my original statement that it is all based on how hard it is to get the geometry you want while staying within what the Tool can handle.

I agree, but the more complex the geometry I want the more sophisticated tool I need to create the geometry, and again the more sophisticate (read more functionality), the more difficult the software will be to learn.

This isn't just a software issue. The more complex any task is, the more complex the tool will need be to achieve that task, and in turn the more difficult it will be to learn.

EDIT: FWIW - I think you're speaking in specifics and I'm speaking in generalities.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Impulse Product Development wrote:

EDIT: FWIW - I think you're speaking in specifics and I'm speaking in generalities.

That is probably true, I do agree that there is more to learn with a larger feature set. I was probably talking more about the product developement curve instead of the curve to learn Pro/E.

I don't know if we could actually say it is function count that effects difficulty. Nope that takes my thoughts right back to functions that do what I want them to do and the radiate example. One quick radiate feature with no sketch instead of 2 sketches and a fill.

I should probably step out of this for awhile and let someone else give some thoughts.

I liked that article about the teacher. That was good.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

For your radiate example the feature can be created with a single feature in ProE although it does require a sketch. Looking at the construction differently you can create the geometry with a single feature and they are probably created the same way in both programs (I'm making some assumptions here).

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

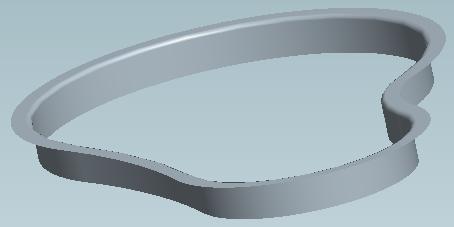

A sketched circle and then a VSS, or a Revolve

I want to see how these new attachments work, that's my excuse and I'm sticking with it, pretty nice actually

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

And if you start with the cylinder as in the example you can just use the edge as the trajectory.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes, I could also have done a nice surface sweep that follows a trajectory and makes the hole setup one feature and can be a complex shape. My point was more toward more functionality not nesecarily making it harder to learn.

Figuring out how to get the geometry your want with the functions available is the hard part. But, now I see how more functions can make that descission harder and maybe add more weight to the idea that more functions make the program harder to learn.

Either way I like having more options to do my work. That means I have more chance of ending up with the part I want.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I understood what you were getting at. My comment was just to point out that you don't necessarily need to create two sketches and a fill in ProE to get the same geometry that you get with the cylinder extrude and radiate feature you used in Solidworks. I've seen some read comments like that and come away thinking that that is the only way you can create the same geometry.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Looks like it could be a pipe with a flange on it, could you put a pattern of holes around the flange creating the flange like this.

(edit) dumb question, just wondering if the outer circle has an axis.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The tube part has the axis, so the outer circle does not need one. Just select the edge click radiate, set the parallel plan and specify the distance. I sure you could put a pattern around it using the center axis, but I already close SW without saving.

That was just an example of a function PTC could implement that would not make Pro/E harder to learn - might even make it easier.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I was originally trained in Autocad and when I got my first cad job with Pro E, I had a negative attitude toward pro-e, because it "made it so hard to do anything." It was true enough at the time, it IS harder to model in ProE when you are not used to parametric modeling. Now I find I only use Autocad for sketching, because of the benefits of using ProE and its related suite of tools. I like autocad if I need something quick, or pretty (although even this is changing as ProE's rendering has gotten better and easier while autocad's gettting less user friendly), or in 2d. Yet for serious engineering and manufacturing I only use ProE, because of the interoperability between ProE and Mathcad, and the nature of parametric modeling. The advantages of Proe in an engineering and/or manufacturing environment are pronounced. The most basic one being when I open a drawing I know that my models are acurate. We have a strict policy against created dimensions at my place of employment and it is a Godsend. Mathcad worksheets take care of most of my mechanics calcs straight from the source model, and if we were inclined it could assist in the modeling itself through parameters and relations. I try to do work in Autocad now and find myself frustrated by its lack of features, where once I held an extremely anti-ProE view. ProE is difficult at first, but in the long run, it's worth it. It's like the difference between an ax and a chainsaw. It's a lot easier to make, learn, maintain and use an ax. You'll still never see me using it unless I have only one or two small cuts to make and it's worth swinging the darn thing.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You can do this with "Fill" feature in pro/e ,when in sketcher select concentric circle it will make circle concentric to surface you just extruded.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We switched from a 2D tool to Pro/E and have found that very rarely do we use the old tool for anything. The only exception that we find is for very complex sketches. This is solely driven by the time factor, we can create very complex 2D profiles in our old product much faster than in Pro/E. With that being said all other work is done in Pro and we have found that since the Wildfire releases the learning curve to train our employees to be much shorter. Getting them comfortable and up to speed has dramatically dropped from the 2001 release. Getting people to understand what they need to do to create all the geometry that is required is easy, getting them to think about the order of creation that makes Pro happy is the hard part. This is what seems to add time to the learning curve, not finding what type of feature they need to create. But understanding what my downstream features and functions will be and what effect does the geometry creation play on that. The tool itself is easy to learn in terms of navigating the software, but the complexity seems to come from understanding what makes a robust model that can except the changes that always seem to come up.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The dreaded fail message, I've learned to pick undue changes when that happens, trying to fix the model always gets something deleted that I don't want deleted. Design intent and keeping a model from failing when you make revisions, takes a lot of experience. When you get to the point when you can resolve the fail message and keep working, you are almost a pro/e guru.

BTW I luv this new edit feature being the notoroius bad speller I am.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I have found that when you make a change and it causes other things to fail the eaiest thing to do is suppress the feature or a clip suppress. This allows you to get out of resolve mode. You can then see the full model tree and then go to the top suppressed feature and edit the deffinition. You can then try and resume all the supressed features and see if that fixed the problem. If not just supress again and edit the next feature.

The problem with resolve mode is that it sometimes takes you into edit the wrong feature or you might not be sure which feature you are editing.

Next, time you get into resolve mode give supress a try. I think you will like it better then undo and trying to redo your needed changes a different way.

WildFire 5 and the option to allow the features to fail is great functionality. It is similar to supressing the failed feature just more user friendly.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Interesting post!

Our engineers are very good at creating designs quickly in Pro/E during the initial phases of the design. The ability to create assembly cuts allow ideas to be created and shared quickly. It is also easy and intuitive. Unfortunately, as the design progresses, the memory needed keeps increasing. Large assembly management and processing speed is a really big issue. The engineers know what they want to create and document. Why is the usability of the design so dependent on how it was created? Designs can become too large to activate even on 64 bit computers. When the assemblies or drawings get too large to activate, then drastic steps in fixing the design occasionally need to be followed. It would be helpful to know if the resources to open the design is getting close to the a preferred set limit BEFORE it is activated and BEFORE the user makes plans to add a lot more information into it. Why should engineers be concerned about monitoring system resources? Their main purpose is supposed to be to come up with the design.

Engineers have also had to recreate designs from scratch when the user who created the design did not follow good design practices. For Pro/E to really reduce the learning curve, it has to allow engineers to be more concerned about processing their ideas then being very proficient with the tool. Many engineers spend a good majority of their time in meetings and coordinating the information about design with everyone in the team. There is just not enough time for many of the engineers to stumble around looking for icons or take extra time trying to remember the correct procedure to create their design ideas. If a user does not use a module for a few months, it often takes them a while to get started in it again. I do agree that Pro/E is becoming easier and improving in many ways with each release.

Don't get me wrong, I really do like the Pro/E tool. It is very capable at creating any kind of design you can imagine. These are just me thoughts (from my observations and discussions with users) on how to make Pro/E more user friendly and reduce the learning curve. We have been using Pro/E as our main design tool for over 15 years.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

View manager will let you create simplified reps of models, which lets you zero in on a specific area you are working in, without having the whole model open. You can save the view, then when you open the model you can open it as a simplified rep, this cuts memory usage way down.

Don't know if that's what you are refering too about memory usage becoming to large, but I thought I would throw it out there.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The most important thing is to learn,accept and follow the best practices when creating Parts, Assemblies & Drawings in ProE / or any other CAD Software program for that matter. That being said you need to find someone that can teach and demonstrate the importance of these. I have been using ProE since 1990.

When I 1st learned ProE I took a 40 hr basic class at PTC Headquarters in Boston, MA. The instructor was very good and stressed!!! the importance of starting with basic shapes, properly constraining sketches to the basic datum planes when possible. and using the dimension references and dimensining scheme you want to see "eventually" on the production drawing. Then as you work on creating your parts add the major features in a logical order refining the part as you go. As you create the details of the part !!!! always be aware of what you are refencing "always use the most basic stable references you can, 1st choice the 3 Base Datum Planes, 2nd major surfaces of the part, 3rd Created Datum Planes, points, axis ....

the above refers to creating basic machined parts, when creating plastic injected molded parts, casting or free-form surfaced parts it gets a little tricky but the same basic principles apply. That is to say choose your references and dimensioning scheme wisely ![]()

When creating drawings use default views, Front, Top, Right Side... use shown dimensions from the model whenever possible. There have been many "discussions / arguements" about this. The best practice in my opinion is to use the shown dimensions. I have heard all the aguments and I don't want to get into that here!

Building your assemblies, if you are not using Top Down Design: Start your assemblies with the most Stable components! parts that are not going to change drastically and assemble other components to them or to assembly level datum planes. Create logical sub-assemblies and assemble them.

If you have the Advanced Assy Design option are you using Top Down Design? I am all for it! if this approach is used properly it can save tremendous amounts of time. I will not go into the details of this at this time because if you are using this technique I'll assume you are somewhat of an advanced user and you know what you are doing.

Attached is a best practices document I have gathered from over the years, it was not totally written by me, but I have added to it and I agree with it for the most part.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I totally agree with what you say here. Knowing how to use the software and knowing how to use the software correctly are two different things. Design intent is always critical to a robust model.

-Greg