Community Tip - Visit the PTCooler (the community lounge) to get to know your fellow community members and check out some of Dale's Friday Humor posts! X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Rectangular hole patterns for flanges

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Rectangular hole patterns for flanges

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Rectangular hole patterns for flanges

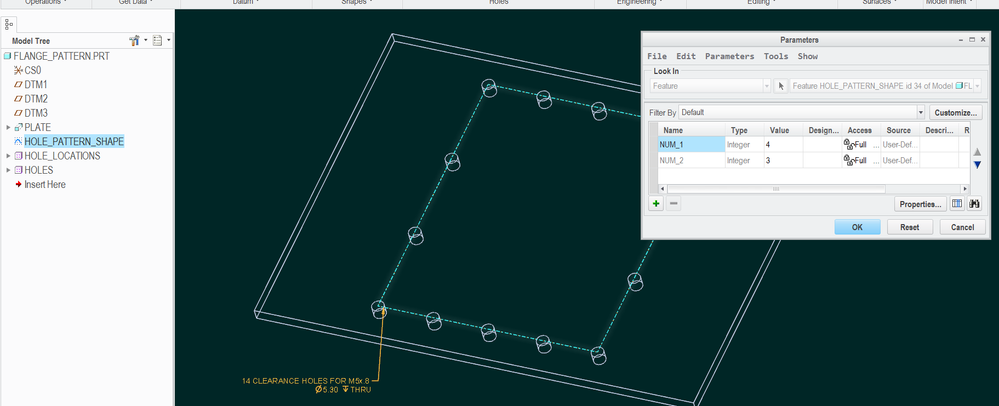

I have rectangular flanges that I have to create hole patterns for. I usually start with making a master cad file that has some automation to it, which allows me to make quick adjustments to the assembly for modified versions/sizes of the product. Rectangular hole patterns have been an issue for me.

My current method is this. I create a rectangular construction sketch, using the center of the hole/duct as a reference. I put a point or circle in one of the corners of the rectangle. I then pattern the sketch using directions, with a relation that takes the length of each side and the number of holes and drives the hole spacing for each direction separate. However, that gives me all of the holes in the middle that I don't want. I just need the outline, so I go in an deselect all the center holes by hand. It's tedious but it works. The problem is when I have to adjust the number of holes, then I have to go through and fix all the selected/deselected locations.

The outline pattern option doesn't work, as that only allows one value for hole spacing for both directions. Fill does not work either for the same reason.

Is there another relation or method I can use? I see that the pattern gives the X,Y position in the tree (HOLE [X, Y]). I should be able to use that to filter out any holes that aren't on an outline position, but I don't know how to access that parameter. I want to keep it all in one pattern, because that will let me use the reference pattern feature when adding hardware to the model in one shot.

Attached pictures are going from a good pattern, to adding additional holes and the resulting pattern afterwards.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

if you need "outline", only then create two separate patterns - first one for "X-direction", second one for "Y-direction".

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I know I can use two patterns. One pattern for horizontal direction. Then use a relation to space vertical direction seed in the right location and create a pattern for that. I was just hoping I could avoid using two patterns.

I don't see a way to obtain the grid position for pattern items. If it was a parameter I could find, it would be easy to write a relation to 'turn off' any point that didn't fall on the outside rows and columns.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

When I've had to do this in the past, I've used the curve driven pattern functionality. I create 4 patterns, one for each side.

Start with a sketch that's a single line for one edge. Make the ends of the line where you want the outer most holes on that edge. Pay attention to the start point of that line (the first end placed). Then create a point at the start point of that sketch. I like to use a sketch with a geometry point because it gives me more control of its position. Then you can pattern the point by curve using the equally spaced option.

Repeat the process for the opposite edge. When creating your curve sketch, make sure that you tie it to the first one so its length with change with it. Similarly, when you create the point sketch, alight the point with the first point in the first pattern. That way you should be able to reference pattern the opposite points.

Lastly, repeat it all for the other two edges. It's a bit cumbersome to set up but should be quite robust once complete.

You might be able to create all 4 curves in one sketch and elect one segment at a time for your point patterns. I'm not sure, it's been a while since I did this.

Another option is to create a sketch with all your geometry points in it. You can use sketcher constraints and construction geometry to keep even spacing, etc. Then you can create your hole features on the first point and use a point pattern to create all the holes at once. It means one pattern vs. four, but adding or subtracting holes means redefining that geometry point sketch, which could get tedious.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Well, your case intrigued me and I came up with this solution:

You can place a point at some distance along a curve. Then this can be turned into a dimension driven pattern of points. And pattern relations can be employed to produce different spacing for the different side lengths of the rectangle. The end result is a single hole pattern that is driven by the sketch feature:

Notes:

- in this implementation, couple of parameters defined in the sketch feature specify how many "spaces between holes" exist on the long and short sides of the rectangle

- there is still a need for 2 patterns because you can't use points on curve as the basis of hole placement.

Feel free to adapt the attached Creo 2.0 file to suit your needs - and if you can, please share any improvements.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Pausob,

That is a really clever solution, where do you define the segments in connection to the sketch? is there some kind of documentation on what params are available?

Best wishes,

Alex

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

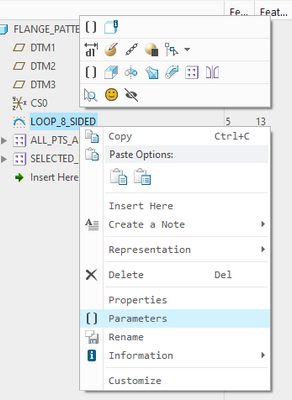

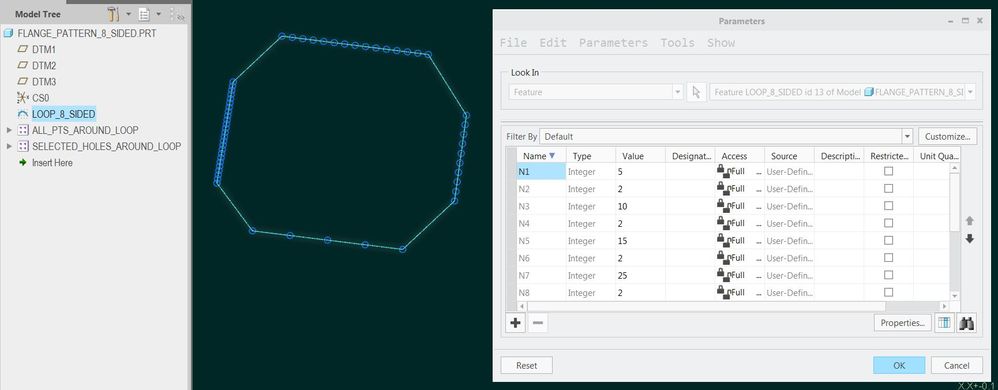

Hi @AlexK , I don't quite understand what you are asking, but with reference to my last post and the model flange_pattern_8_sided.zip,

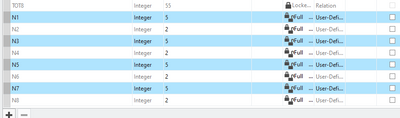

you can change the "LOOP_8_SIDED" feature parameters "N1" - "N8" to vary the # instances in the 8 segments of this sketch.

For example:

Generates this:

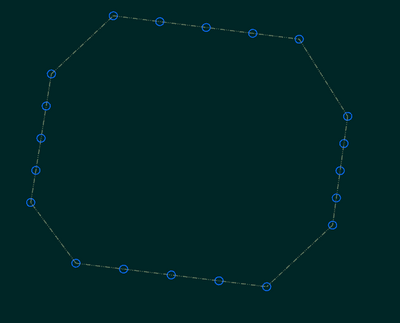

And you are also quite free to modify the shape of the sketch LOOP_8_SIDED

(by dragging the vertices of the polygon - do not delete entities or dimensions or the relations will break), e.g.:

If you are asking how it all works, examine the pattern relations inside "ALL_PTS_AROUND_LOOP" pattern feature and feature relations inside the "LOOP_8_SIDED" sketch.

Now that I look back at this critically, it is rather too complicated for its own good. Good luck!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Pausob,

Thanks for the reply, now I've understood how it works! Before I didn't see the relations inside the pattern feature.

Best wishes,

Alex

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

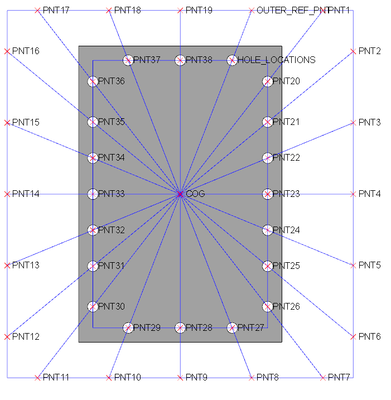

I often use the method using four patterns that @dgschaefer refereed to, but was looking for something to save on all the copygeom features when using top-down modelling. I really like the method @pausob described using relations, but can't figure out how to start the pattern a away from the corners (other than manually turning off each corner instance)

By using an outer reference sketch, the distribution of holes on each side can be controlled. I've attached an example part, but the images below shows what I mean. I tried the ellipse first, but think the reference rectangle gives more control. It's probably only worth it for top-down modelling.

Sam

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Another option to consider is to extend the 4-sided concept I demo'ed in previous post into an octagonal shape to handle the cases where you don't want the corner points. more control, so more dimensions to manage...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you, but to be honest, I kind of forgot how I did this. But turns out I had a 16-sided version that I could quickly trim down to be the octagon. The result is quite generic - each segment can have a different # of instances:

Edith the highlighted sketch to define placement. Edit the parameters of the sketch feature to drive the # of pattern instances along the edges of the loop. Edit the relations of the 1st pattern feature (not its pattern relations) to shift the entire hole pattern along the boundary.

Creo4 version file attached.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I would use a pattern table but put 2 datum planes in first one for X direction one for Y at the location of the first hole relate the first hole to the datum planes create you pattern table from that. Each hole gets an x-y coordinate from the datum planes. By moving the datum planes you can move the whole pattern.

Also you can save the pattern and re-use it in a mating part i.e. an aperture and cover.