Community Tip - Want the oppurtunity to discuss enhancements to PTC products? Join a working group! X

- Community

- Creo+ and Creo Parametric

- Analysis

- Creo Flow Analysis - Simulate Rate of Increase in ...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Creo Flow Analysis - Simulate Rate of Increase in Pressure on a Piston

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Creo Flow Analysis - Simulate Rate of Increase in Pressure on a Piston

I am using PTC Creo 7.0 and want to analyse the behaviour of pressure in a braking system. I was thinking to use a simplified model consisting of a length of brake line (4.8mm bore) connected to a piston inside a cylinder. (35mm diameter with 0.5mm stroke)

I would then introduce restrictions in the brake line and analyse the effect on pressure build up behind the piston.

Does anyone have experience with a model similar to this?

As a starting point, I have created a transient flow analysis of a simple brake line with a restriction, but without the piston element: the brake line is set with 8000000Pa inlet pressure and 0Pa outlet pressure but this is not yielding the expected results (i.e. a ramp up in pressure from zero, finishing with the outlet pressure equaling the inlet pressure).

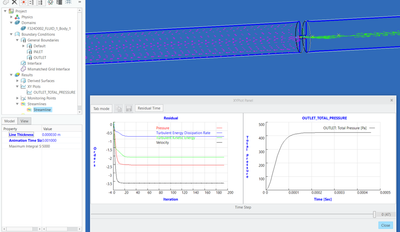

This is the result I obtain currently:

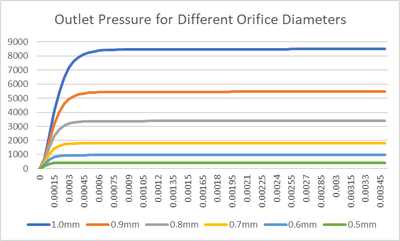

Looks o.k. so far, however if I simulate a number of different restriction diameters, I get this:

I would expect final outlet pressure to equal input pressure once the system reaches equilibrium if I have modelled it correctly - the results make me think my chosen model settings are wrong somewhere.

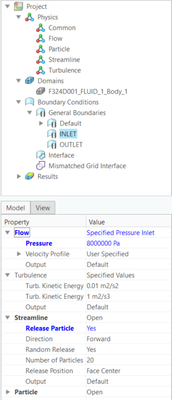

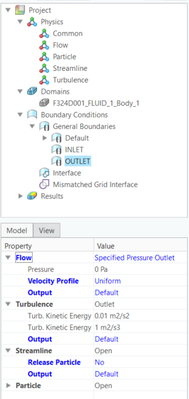

Inlet and Outlet settings are:

Inlet:

Outlet:

Any ideas where I might be able to improve this?

Thanks very much for any help!

- Labels:

-

Comput_Fluid Dynamic

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi this is a very interesting case, creo flow can simulate this. please contact ptc support or Simerics support directly if you want to get help. Basically you need to use moving/sliding mesh to model piston moving and add restriction to your brake line. Thanks

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you @cfdgeek - I think part of my issue was that my license would not allow creation of a moving/sliding mesh. I was trying to come up with a workaround without the need for the moving piston element by specifying appropriate boundary conditions for each end of the tube.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Got it. In this case, we can use expression to apply a transient boundary condition based on time steps.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you - would you have an example of how I'd specify that expression?