Community Tip - Your Friends List is a way to easily have access to the community members that you interact with the most! X

- Community

- Creo+ and Creo Parametric

- Analysis

- Force measures for weld calculation

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Force measures for weld calculation

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Force measures for weld calculation

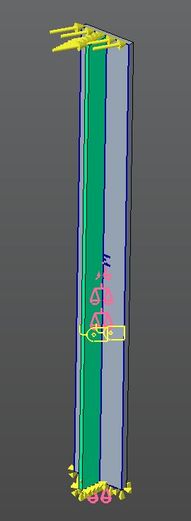

I want to try to extrapolate force (tension) from a welded structure to perform a calculus as prescribed by EN1993-1-8.

I want obtained the forces by measures of a simple truss loaded by transversally.

On each side of the green beam I want to simulate the presence of two filled weld with a=5mm.

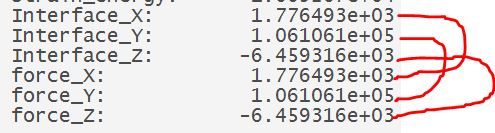

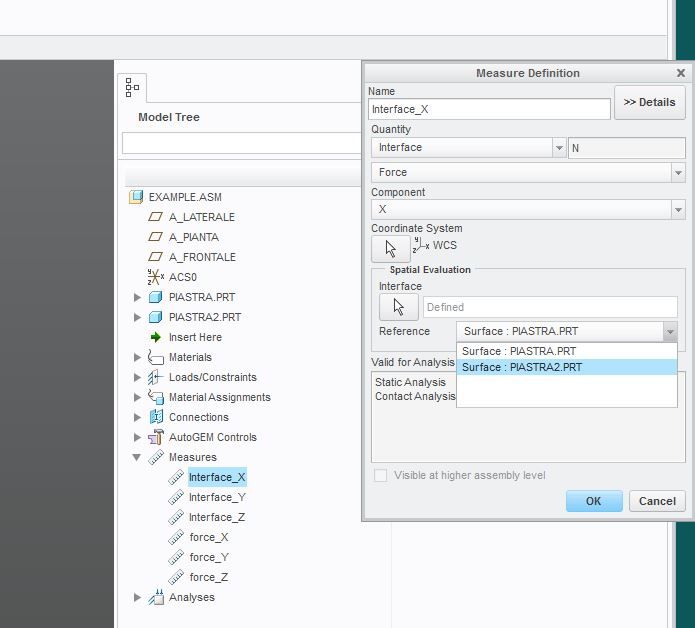

I used two kind of measure: Force and Interface.

Looking on the Help it seems the proper one should be the force measure, but, in this case, I think both should be right.

Exept that the results are different, so which are the right?

Thanks

Bye

Solved! Go to Solution.

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

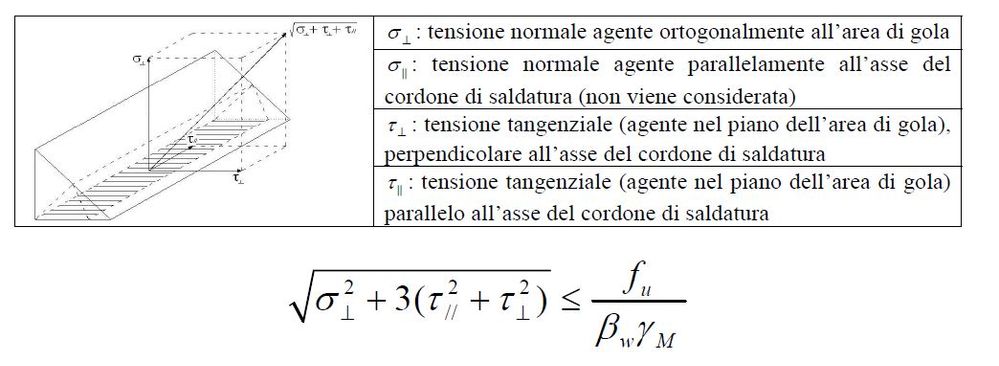

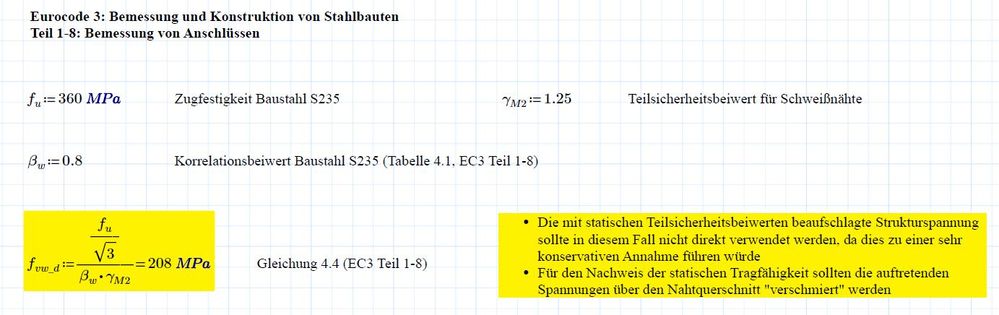

I think EC3-1-8 is not possible for FEA

my info (in german):

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks, after I'll try to translate from german.

Eurocode apart, I don't understand why there is difference between the two measure.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

your example is in creo 5...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Tomorrow I gonna attach a new one in Creo 3 ![]()

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

... you need force AND moment ...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

So what you've done is to change the reference in the interface measure definition.

Yeah, I had not seen this option in the measure.

But at least now it all adds up with my initial idea reasoning that the two measure must be egual.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I've translated from German your post regarding to the ability to use FEM's datas for EC calcs.

If I've well understood (...) your focus is not over the stress results taken from the measures, but it's about the use of coefficients imposed by the EC (that presume raws calcs of stress) togheter with precise stress results. All of this brings to be excessively conservative.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks a lot for the document. I'll read it asap!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The EC3's theory establishes the use of a "spreaded tension" all over the section of the weld.

This tension will be reworked through a serie of coefficients to take back the calculated stress to "the real one".

The coefficients that permit all of this are obtained by tests over welded samples, with a certain shape and material (especially construction material like S235). One must always try to trace it back to welded joints like these to maintain valid the calculations.

FEM permits to obtain tension punctuals evaluations over whatever welded links geometrie.; trace we back to the model of a normalized tension over the entire section means loosing much of FEM's potentialities.

However, I believe that, if one want really following the EC norm, the method of the normalized/"speaded" tension evaluation is applicable (through those measures which I've asked in the firstes posts of this thread).

By going back to FEM's potentialities, for welds it is proposed the FKM use, which they need:

- the punctual evaluation of max tension (sigma, tau) of the section;

question: I start by saying that I've not had access to the FKM-Guidelines yet, but in the example (by Paul Kloninger) one considers only the tau_yz and not the tau_xy. This last one should be 0 in the example (no torsion stress) but I would say it should be considered generally. In this case, should it be considered by this formula radq(sigma_z^2 + (tau_yz+tau_xy)^2) [as in the Paul's example at page 6] or this one radq(sigma_z^2 + 3(tau_yz+tau_xy)^2) ? - the definition of a rounded weld seam (so, the weld seams must be modeled and insert within the model)

- a dense mesh on the weld seams

From what I've understood, it doesn't need an elasto-plastic material neither for weld seams nor for the groun material (so the simulation remains in linear field) since one utilizes the plastic shape coefficient n_pl, if the structure's strain remains between 1-5%.

In the Paul's document it hasn't been written, but I would say that if the rule of 2*a>=t is respected, then you can consider the weld as a "full deep" (I don't know the right term in english...). So there is material continuity among plates and so you can avoind the use of a contact (non-linear analysis).

By utilizing other coefficients obtained by tabs (which I've not seen yet) like alpha_w, j_s, j_p, j_z, one arrives to the calculation of a global coefficient j_ges where:

j_ges > 1 OK

j_ges < 1 BAD

Do I understand correctly?

A personal curiosity

At the end of page 6 there is the term "stainless steel" as "rostfrei Edelstal". If I translate (from ENG to GER) the term "stainless steel" I have "rostfrei Stahl", while if I translate back to front (from GER to ENG) the term "Edelstahl" I have "stainless steel". So it seems like to say "stainless stainless-steel". Which is the right translation?

------------------------------------------------------------------------------------------------------------

Regarding welds, I take this opportunity for invite you to vote two ideas:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

So I have to take in account only sigma and tau orthogonal to the weld section?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

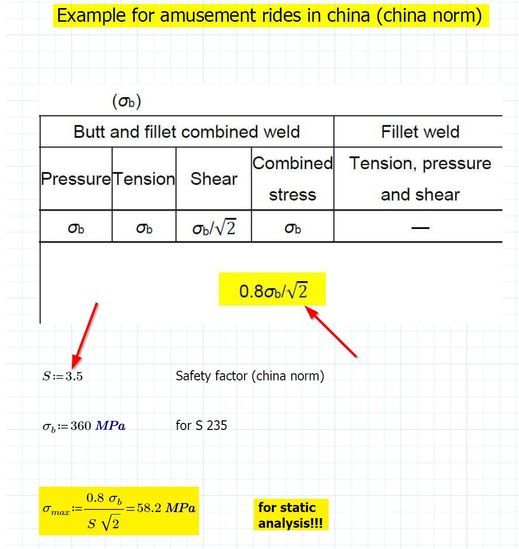

sigma "orthogonal" (normal stress) and

tau "parallel" (shear or torsion)

example att.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

stainless steel = in german:

- rostfreier Edelstahl or

- Edelstahl (simpler)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

"full deep" weld will be understood in English but it is more commonly called "full penetration"

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

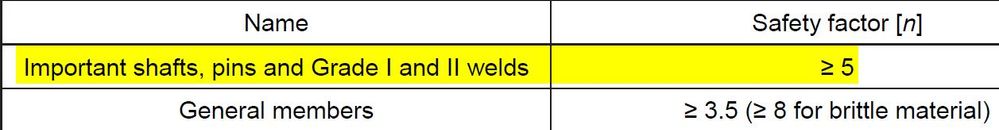

I believe we have a similar issue in many requirements / industries where higher safety factors were used to account for the real stress vs the stress found by simple hand calculations. For example do we still need 8X safety factor when we have calculated the stress 3X higher than hand calc. because of more accuracy with FEM? We still have so much in our modern world still based on empirical data "recipies", making the switch to FEM extra difficult when such things have been written into laws and regulations!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

yes, ec3 is very conservative..

but a most problems i have in CN:

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

sometimes

safety factor is 5 !!!