Community Tip - Did you get an answer that solved your problem? Please mark it as an Accepted Solution so others with the same problem can find the answer easily. X

- Community

- Creo+ and Creo Parametric

- Customization

- CREO Parametric - Number of factets on an STL file

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

CREO Parametric - Number of factets on an STL file

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

CREO Parametric - Number of factets on an STL file

Hi,

I use CREO Parametric 9.0 Student Eddition as a Hobbyist. When creating an STL file (Save as STL) for a 3D printer, I observe that the number of facets on circular srfaces is relatively low.

My question is : How to increase the number of factets, in order to get more precise circular surfaces ?

I foud this article in the CREO support, but it seems to be valid for another software : https://support.ptc.com/help/creo/ced_modeling/r20.5.0.0/fr/index.html#page/ced_modeling/OSDM_Main/Parts_23.html

Is there a limitation of the Student Edition ?

Thanks for your help

Solved! Go to Solution.

- Labels:

-

General

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

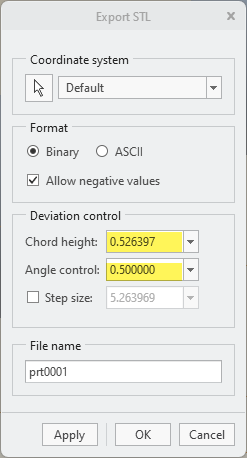

Chord height needs to be minimized to yield the best approximation of model geometry during tessellation. This will result in max number of facets when generating an STL.

Explanation of chord height:

Controlling the Quality of Export (ptc.com)

When exporting do the following:

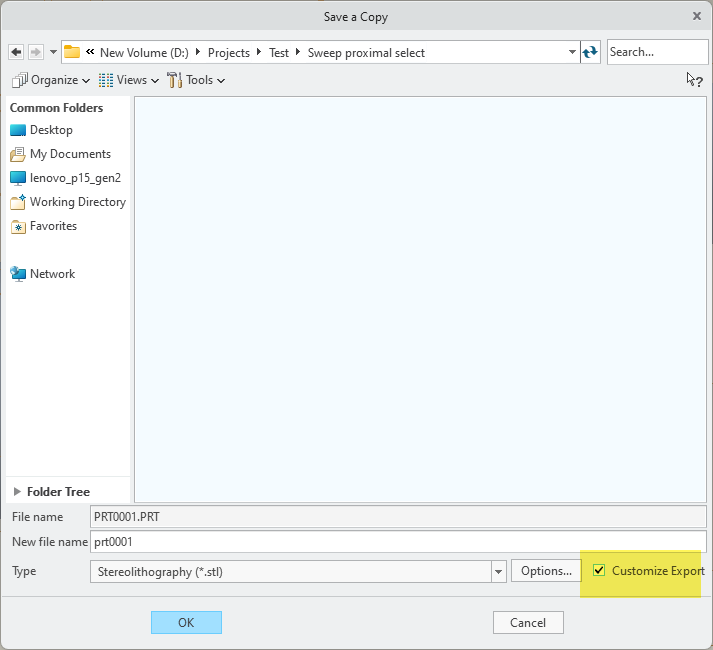

Select the customize export option

Set the chord height to zero and Creo will minimize it with the lowest possible value for the model.

Set angle control to 1

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

- set absolute accuracy in model

- set lower absolute accuracy value in model

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Changing the absolute accuracy of the model won't change the number of facets.

I have created a video to show you how you can change the way the facets are generated.

The video is made in Creo 10. However, it is the same in other versions of Creo.

You can watch the video through the following link

https://technologiecampusdiepenbeek.be/PTC_Community/STL_facets-Creo_10.mp4

I hope this will help you solve your problem.

Best regards,

John Bijnens

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi John,

Thank you very much for your help ! It works perfectly and I can now specify the accuracy of my STM models.

Thank you for your reactivity 👍

Best regards,

Yves

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

attached video shows that absolute accuracy value sets lower limit for STL export.

Martin Hanák

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@MartinHanak is correct in stating that the model accuracy can affect the tessellation as it sets the lower bound for chord height. If a given model had an accuracy that was so large it prevented features from tessellating with fidelity suitable for input to a process, then one would consider changing the accuracy of the model.

The lower bound for the chord height is a function of part accuracy while the upper bound corresponds to the model size.

In practice, I have never had to resort to changing model accuracy to get STL files suitable for even the highest end 3D printers. Our model accuracy is set such that it is tighter than the resolution of the printers so lowering accuracy would not yield better results from the printer.

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Chord height needs to be minimized to yield the best approximation of model geometry during tessellation. This will result in max number of facets when generating an STL.

Explanation of chord height:

Controlling the Quality of Export (ptc.com)

When exporting do the following:

Select the customize export option

Set the chord height to zero and Creo will minimize it with the lowest possible value for the model.

Set angle control to 1

Involute Development, LLC

Consulting Engineers

Specialists in Creo Parametric

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thank you so much for your tip abd your reactivity., It works perfectly and now, my STL model are very accurate 🙏

Best regards,

Yves

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Excellent answer I have this stored as a map key, and do it all the time.