Community Tip - You can change your system assigned username to something more personal in your community settings. X

- Community

- Creo+ and Creo Parametric

- Customization

- Did you know about reference parts

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Did you know about reference parts

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Did you know about reference parts

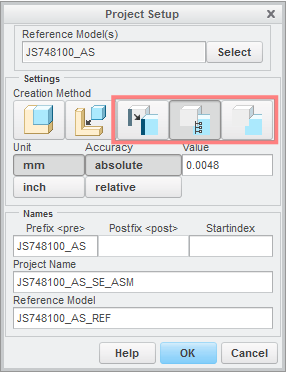

In many companies, electrode designers may not change released models of the tool design, but often a simplification of these models is desirably. The interactive creation of reference models is time consuming and a boring, repetitive task. SMARTElectrode provides a functionality to create a reference model in new assemblies. The reference model is a copy of the original models - like reference model in mold and Creo NC - and can be created in different ways:

- Copy geometry and solidify

- Inheritance

- Merge

If the reference model is created from an assembly, all selected models will be copied into the reference model.

The usage of reference models offers some advantages:

Simplify and prepare

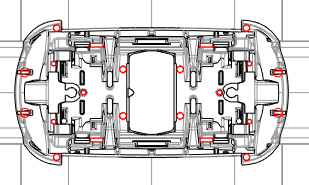

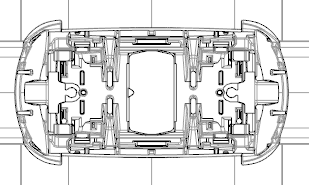

Inside the reference models all changes can be done without modifying original models. Ejectors and cooling can be suppressed (inheritance only) or removed, surfaces can be collected for easier electrode extraction and color codes can be used to separate different electrodes.

Reference model before and after suppressing ejector pins and inserts.

Make it independent

Manual update can be enabled for copied geometry to make sure that no changes of the sources are regenerated automatically . This ensures that electrodes remain unchanged until the designer wants to update the geometry. This avoids unintended failed features due geometry updates in the background.

We recommend to use independent reference models with inheritance for best user experience.

Related SMARTElectrode options

- SET_COPY_GEOM_INDEPENDENT - create reference model with manual update (=yes).

- REFERENCE_METHOD - method to be used for assembly creation (=3 - inheritance):

Use current model (for assemblies).

Use current model (for assemblies). Use original models.

Use original models. Use copy-geom and solidify for reference model.

Use copy-geom and solidify for reference model. Use inheritance feature for reference model.

Use inheritance feature for reference model. Use merge for reference model.

Use merge for reference model.

This thread is inactive and closed by the PTC Community Management Team. If you would like to provide a reply and re-open this thread, please notify the moderator and reference the thread. You may also use "Start a topic" button to ask a new question. Please be sure to include what version of the PTC product you are using so another community member knowledgeable about your version may be able to assist.

- Labels:

-

SMART Products