Community Tip - Learn all about PTC Community Badges. Engage with PTC and see how many you can earn! X

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Fatigue and Crack Growth

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fatigue and Crack Growth

Hi to all,

Looking for some help from anyone with experience in fatigue calculations.

I have the attached problems as part of an assignment but the supporting literature I have been given is not overly helpful. Essentially I think that I have either done some of the programming incorrectly or equally likely my units are wrong. As I suggest, the material I am working from is pretty light in explaining the units.

Any help appreciated.

Andy.

Solved! Go to Solution.

- Labels:

-

Math Homework

-

Mechanical_Engineering

Accepted Solutions

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes. You're basically doing a weighted average of stresses and cycles. Think of it as a percentage of fatigue "life." Each of the stress levels and number of cycles uses a certain percentage of life. (Miner's rule.) Each year there are (in your problem) six stress levels and each level has so many cycles. What would the equivalent stress be for one level for all the cycles in the year?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

PS I am using MCP3.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

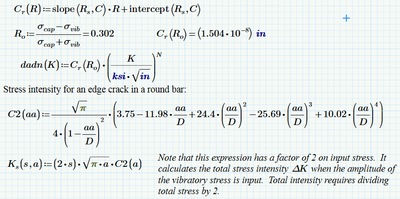

Think I have had a bit of time to reflect on this and think that the issue is the way I have set up the calculation. I think the cubing function in the Paris law formula i.e. (dK)^m which is (dK)^3 in this case is causing the units of dK to be cubed. This I don't think should be the case and it is just the value of dK which should be raised to the power of m? In which case I get a sensible crack growth figure but can anyone comment/ tell me if this is correct and if so what I should be doing differently in MC to get this to work properly?

Thanks

A

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

You've got it almost right.

I'd send your sheet, but I'm working in 4! See attached xps!

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fred,

Many thanks for that. I think I tend to agree with you on the units for C although it does not seem well documented...

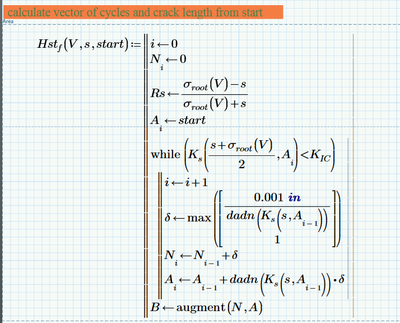

The last part of my problem is to calculate the size of the crack for each year.

As opposed to going through manually calculating each da and adding this to the current a i.e. a is the original crack length, da is the amount it increases in year 1 and then you would sum these to get the length of crack at the start of year 2 (a2).

Instead of doing this manually I am trying to think of a more sophisticated way of getting Mathcad to do this for me. I am thinking of a for loop in a programme but it is a bit mind boggling as in order to calculate da you need dK and to get dK you need da (as you need the current a for the previous year). Any thoughts on how to approach this cyclic argument?

Thanks,

Andy.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

K is a function of applied stress and a.

da/dN = C*K(a)

this is a differential equation in a as a function of n. suggest odesolve or rkadapt.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi again Fred,

I am not familiar with those functions in Mathcad.

I think the issue I have here is that as the crack gets larger the dK will change so the graph I will end up with will be similar to e^x i.e. the crack grows exponentially.

I also see that da/dN is the rate of crack growth.

In my problem, a (0.0005m) is the original crack size which increases after a year of stresses by da (0.004m) meaning the crack is ~0.005m at the end of year 1.

If I re-write dK as a function of a and da as a function of a you can create a manual method of getting the crack sizes each year with the next year's crack size being 0.141m

However, this is quite 'handryalic' and wonder if there is a way of automating this process in MC?

Cheers,

Andy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Although... Saying that, I may have the wrong end of the stick as following this routine, the crack increases by 20.4m in the following year which I can't see being correct...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

How to solve a differential equation.

The reason the crack doesn't grow that large is because K grows to be equal to K_IC, and the slow crack growth changes to abrupt brittle fracture.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi Fred,

I imagined you would have a very jazzy method for looking at this. Not sure I entirely follow it but not withstanding that, the regime I am to follow is attached taken from the rather confusing reference material I have been given.

Thanks,

Andy.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Andy,

Really isn't all that jazzy; the challenge is to determine when the crack converts from slow growth to abrupt fracture. For that reason, most of the time the change in cycles is taken in steps as your documentation suggests.

I've dealt with this. First with pressure vessel steel in thick sections (you're in ship building, so that's probably your area.) Second in high strength brittle steels and aluminum (helicopters and airplanes.) I've excerpted things from a real problem. (Sorry, proprietary info stops me from transmitting the actual document.) The calculation is cycles to crack rapid propagation. (Stress is a rather complex function of airspeed, so V is airspeed and I've left off the actual function.) I've also attached a working version 15 document for crack growth in aluminum. This was crack growth in aluminum, I found actual data and fit the curve rather than figure out the Paris Constants.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Thanks Fred,

All very useful background and I appreciate your experience in a variety of fields 'alien' to me in engineering.

As my problem is to plot crack length not growth rate against time, I think I will just opt for the iterative method in the material I sent through previously. I am going to try and work on a programme that does this for me and any examples of things similar to that you've done as always appreciated.

Andy.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

@awibroe wrote:

Thanks Fred,

All very useful background and I appreciate your experience in a variety of fields 'alien' to me in engineering.

As my problem is to plot crack length not growth rate against time, I think I will just opt for the iterative method in the material I sent through previously. I am going to try and work on a programme that does this for me and any examples of things similar to that you've done as always appreciated.

Andy.

If you look carefully, there are at least two "crack length" programs in what I sent you.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fred,

Good timing, I noticed that and have worked on the attached in the last hour and these are very much based on your programmes you sent so thanks!

What I do observe however, is that these suggest that by the end of ~8.301E+5 cycles the crack length has reached ~1.1m.

What I would say is this A seems odd and B this does not sit well with the problem I am attempting to solve. Either, my mathematics are wrong or this is a trick question (not inconceivable).

What do you recon is more likely?

Thanks,

Andy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

I think there's an error in your calculation for equivalent stress

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fred,

So what you are saying is in the attached where it says "if sigma r has N values" the N is not the number of different values of stress ranges (in this case 6) but is the number of cycles those 6 stress ranges experience?

Andy.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Yes. You're basically doing a weighted average of stresses and cycles. Think of it as a percentage of fatigue "life." Each of the stress levels and number of cycles uses a certain percentage of life. (Miner's rule.) Each year there are (in your problem) six stress levels and each level has so many cycles. What would the equivalent stress be for one level for all the cycles in the year?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fred,

I take your point. This is as usual with my learning bad course material.

My sincerest thanks for your help once again.

Andy

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

And if I had taken the weighted average correctly, there would be a different looking answer.

Attached is the corrected file.

Sorry for the error!

Fred

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

So in using the actual stress values the result is not overly different...

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Fred and all,

Sorry I have been going about this in drips and drabs.

I have tried two methods of this (all be it manually) both giving very different outcomes. In one method I have increased the number of cycles after each crack growth by 1E+6 and the other method by increasing the number of cycles by the yearly cycles i.e. ~3.5E+6 cycles. The outcomes are in the attached but in one case after a year the crack is up to 3.14m and the other it is only 0.005m.

I am left quite confused but assume this comes down to this methodology giving approximate outcomes. If anyone is a guru in this arena, appreciate some input.

Also appreciate anyone being able to suggest an automated way of doing this.

Thanks,

Andy