Community Tip - When posting, your subject should be specific and summarize your question. Here are some additional tips on asking a great question. X

- Community

- Creo+ and Creo Parametric

- 3D Part & Assembly Design

- Re: Barrel Cam

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

Barrel Cam

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Barrel Cam

Hi,

I have tried to make a barrel cam. I have seen previous threads about this topic on this forum. I know that this is tricky geometry and I have tried different methods. I have attached files below with the cutter tool assemblied with a slot constraint to check for interference. There is very little interference but it is there and I want to see if I can model it with no interference. This part was previoulsy made by pattern a revolved cut in increments of .005. This way is not wrong but I wanted to see if I could do it another way. I had seen a previous response by Tim McLellan but I couldnt quite get his method to work. I think the sharper the corner the more the geometry gets distorted.

- Labels:

-

General

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Multiple separate cuts will give you a pretty accurate slot, but the model will be very heavy and useless for actual machining. I've been unable to find any other method that can accurately reproduce what is really happening between the slot and the follower (or cutter). At this point I've given up trying to produce a machinable model in Creo Parametric and have shifted to using software that can generate G-code based on the cam profile without needing an actual cad model.

Fundamentally, we need something like 3D sweep that can accurately create geometry from all interferences between the model and the cutter (or cam follower.)

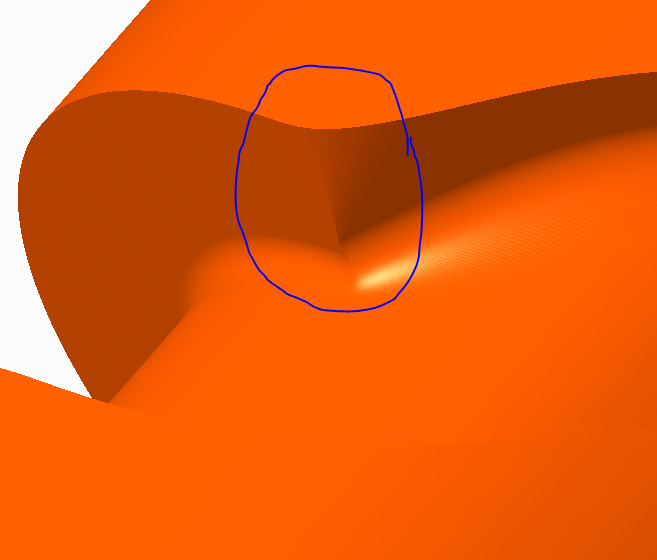

I have done some initial testing of a software called MechDesigner from PS Motion. It does appear that they can produce geometrically correct models in SolidWorks, as long as the transitions are not so sharp that the cam becomes undercut. For example, they can't accurately reproduce this area: (shown here in Creo with separate cuts every 0.5 degrees)

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

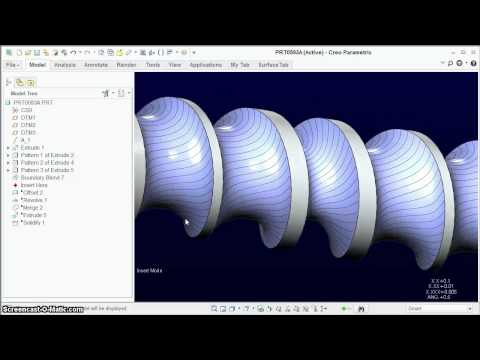

From what I can tell in Solidworks, they have codified the operation much the same way as I did in the linked video above and discussions. It is still an iterative series of revolves. How they actually finish up the operation is not immediately obvious. There is also the motion profile in Mechanism, but that is very crude and imprecise. The resulting element is a faceted body.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

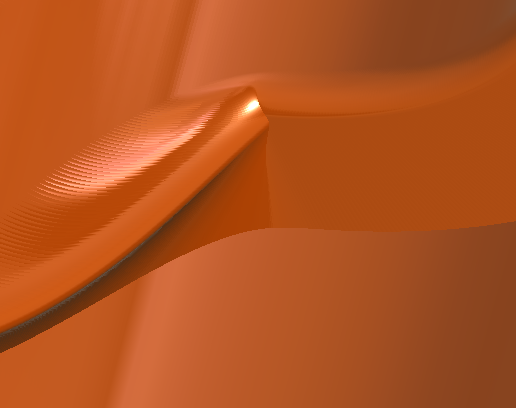

Thank you guys for the replies. I did check out those videos and they were really neat. I had seen the thread on the globoidal cam modelling. I tried to make a boundary blend between two curves and then offset from the mid boundary plane. It is close but not a 100% and I am unsure as to why.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Can you share where the deviation occured?

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi,

Thank you for the response. I have attached a zip file containing my model. It includes an assembly with the barrel cam and the "cutter tool" is assemblied with motion. When it goes through its motion there is interference. This happens on the turns. When you drag the motion highlights in red.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

The bottom of the groove also needs to be iterated, that will remove the "wrinkle".

There is nothing simple about this process. If I did this daily, I would know where to go, but this has been too long to be accurate without reviewing previous efforts. There are 10 wrongs ways to do this, and only one right way.

Use the analysis curvature tool to see if your edges are "in plane".

You will see the bottom of the cut twists while the cylinder edges follow the cylinder's curvature.

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

We've had a very lengthy discussion with a spherical version of this here:

https://community.ptc.com/t5/Creo-Modeling-Questions/Modeling-a-globoidal-cam/m-p/375584#M94825

I have also made a couple of video's related to the operation of mimicking this type of feature:

https://www.youtube.com/watch?v=3TGlKCftl4A

https://www.youtube.com/watch?v=S1258VXo2p4

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Notify Moderator

Hi, even if it has been passed a lot of time might you share the Creo File?